Top Answers Pack

-

CNC lathes provide high-precision turning for automotive, aerospace, and industrial parts.

-

Vertical lathes excel at large-diameter workpieces, while horizontal lathes handle long shafts and rods.

-

Standard delivery from China factories is approx. 30–50 days, depending on customization.

-

Most buyers require CNC-controlled lathes for automation and repeatability.

-

Warranty periods typically cover 12–24 months with spare parts support.

-

Remote installation guidance is available from most suppliers.

-

Energy consumption varies by spindle power, approx. 5–12 kWh per shift.

-

ROI is typically achieved within 12–24 months due to cost-effective sourcing.

-

CE and ISO certifications are standard for international compliance.

-

Custom tooling and software options are available to match specific production needs.

Sections

Section 1: Introduction to CNC Lathes

CNC lathes are essential for precision turning of metal parts in industries like automotive, aerospace, and machinery manufacturing. Choosing a reliable China CNC lathe manufacturer ensures competitive pricing, high performance, and robust after-sales support.

FAQ Block:

Q: What is a CNC lathe used for?

A: CNC lathes are used for turning, drilling, threading, and cutting metal workpieces with high precision.

Q: Are Chinese CNC lathes reliable for industrial production?

A: Yes, CE/ISO-certified machines with durable components are commonly supplied.

“Precision turning defines the quality of your metal components.”

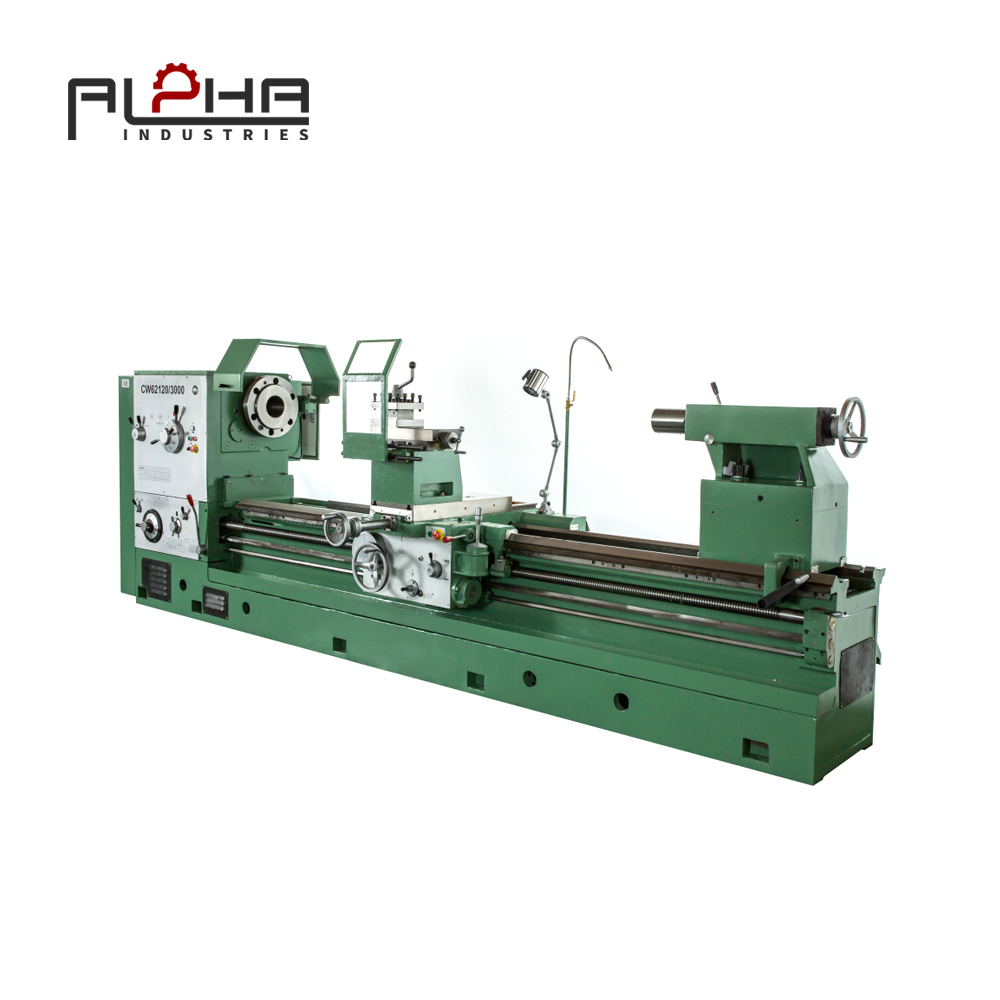

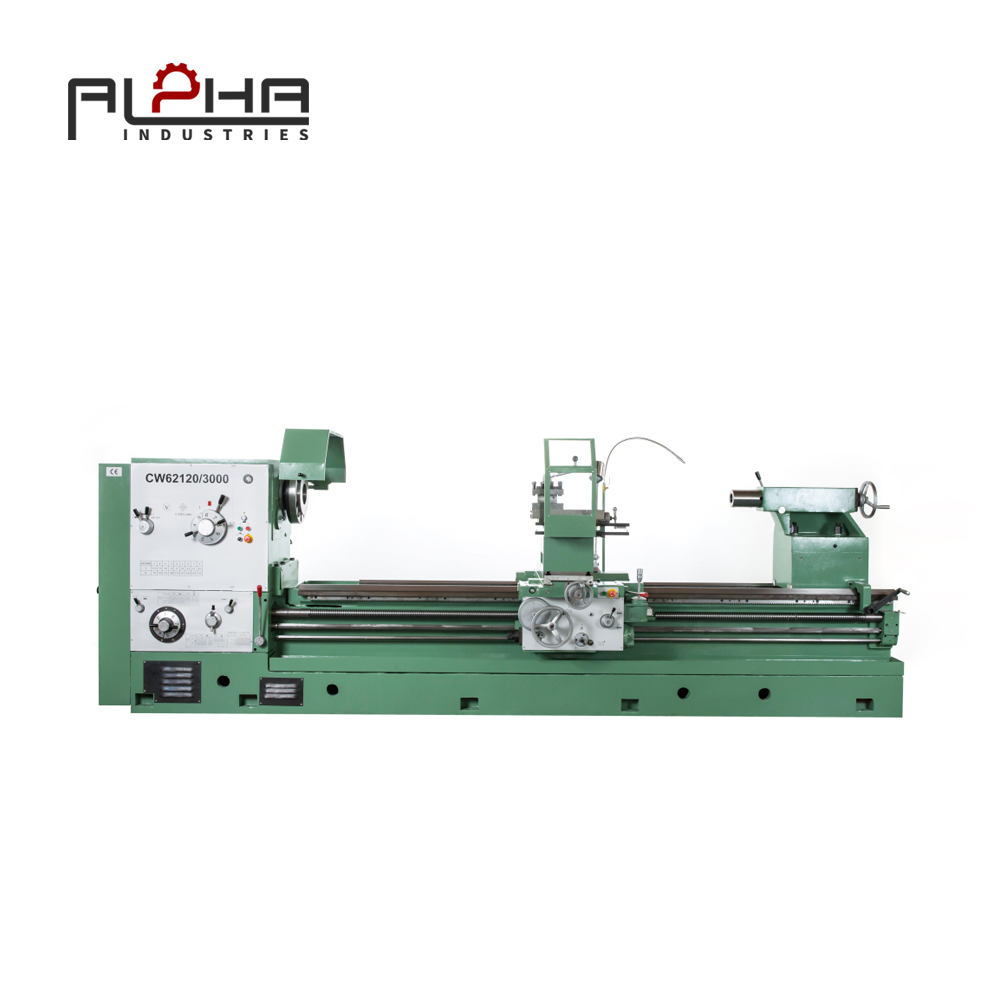

Section 2: Vertical vs Horizontal CNC Lathes

Vertical lathes are suitable for large-diameter workpieces like automotive discs or aerospace components. Horizontal lathes handle long shafts, rods, and cylinder parts. Selection depends on the part geometry, production volume, and required precision.

FAQ Block:

Q: When should I choose a vertical CNC lathe?

A: For large-diameter, heavy workpieces requiring precise circularity.

Q: What is the advantage of a horizontal CNC lathe?

A: Ideal for long workpieces and high-volume production with stable machining.

“Vertical for diameter, horizontal for length—match your lathe to the part.”

Section 3: Technical Features to Evaluate

Key factors include spindle power, rotational speed, CNC control software, tool compatibility, and bed size. Chinese suppliers offer customizable options to fit specific industrial applications.

FAQ Block:

Q: Can spindle speed and tooling be customized?

A: Yes, most manufacturers allow variable spindle speeds and tool holders.

Q: Are CNC control systems included?

A: Yes, CNC control is standard for automated and repeatable operations.

“Specifications are the backbone of precision and productivity.”

Section 4: Cost, ROI, and Efficiency

Evaluating total cost of ownership is critical. CNC lathes reduce labor, improve material utilization, and enhance production efficiency. ROI is often achieved within 12–24 months when compared to manual alternatives.

FAQ Block:

Q: How do I calculate ROI for a CNC lathe?

A: Consider purchase cost, labor savings, material efficiency, and production throughput.

Q: Are CNC lathes more cost-effective than conventional lathes?

A: Yes, automation reduces errors, rework, and operational costs.

“Invest in precision today to save cost tomorrow.”

Section 5: Delivery, Installation, and After-Sales Support

China CNC lathe manufacturers typically ship within 30–50 days. Remote installation guidance, operator training, and spare parts support ensure smooth integration into global production lines.

FAQ Block:

Q: Is remote installation guidance provided?

A: Yes, remote guidance and technical training are standard.

Q: What warranty coverage is typical?

A: 12–24 months depending on machine type and supplier.

“Reliable after-sales support ensures long-term operational uptime.”

Section 6: Comparing Suppliers

When selecting a CNC lathe supplier, buyers should evaluate machine specifications, certifications, delivery times, warranty, and after-sales support. Visiting the factory or requesting video demonstrations helps assess machine quality.

FAQ Block:

Q: How do I compare different CNC lathe manufacturers?

A: Check specifications, certifications, warranty, lead time, and customer references.

Q: Can suppliers provide customized options for automation or tooling?

A: Yes, most factories offer customization to match production needs.

“Supplier selection is as important as machine selection.”

Section 7: Integration with Other Machines

CNC lathes often operate alongside milling machines and press brakes to form integrated machining lines. This improves workflow efficiency and reduces manual handling.

FAQ Block:

Q: Can CNC lathes work in a production line with milling machines?

A: Yes, integration enhances efficiency and precision across operations.

Q: Are press brakes compatible with lathe operations?

A: Yes, combining lathes with press brakes allows complete metal part fabrication.

“Integrated machinery boosts productivity and ensures consistent quality.”

Conclusion

China CNC lathe manufacturers provide cost-effective, high-precision turning solutions for global industrial buyers. Vertical and horizontal CNC lathes are suitable for diverse workpiece sizes and applications.

Explore complementary equipment like Milling Machines and Press Brakes to complete your machining workflow. For quotations, detailed specs, and expert guidance, visit our Contact Us page.

FAQ

Q: What is the difference between vertical and horizontal CNC lathes?

A: Vertical lathes handle large diameters; horizontal lathes handle long shafts efficiently.

Q: How long is the typical delivery from China?

A: Approx. 30–50 days depending on customization.

Q: Are CNC control systems included?

A: Yes, most machines come with full CNC control for automation.

Q: What is the warranty period?

A: 12–24 months depending on supplier and machine type.

Q: Can machines be customized?

A: Yes, spindle power, diameter, and tooling can be customized.

Q: Is remote installation guidance available?

A: Yes, manufacturers provide online setup and operator training.

Q: What industries commonly use CNC lathes?

A: Automotive, aerospace, industrial components, and mold making.

Q: How do I calculate ROI for a CNC lathe?

A: Consider purchase cost, labor savings, material utilization, and throughput.

Q: Are spare parts available?

A: Yes, suppliers provide critical spare parts for long-term operation.

Q: Can CNC lathes integrate with other machines?

A: Yes, combined with milling machines and press brakes for complete production lines.