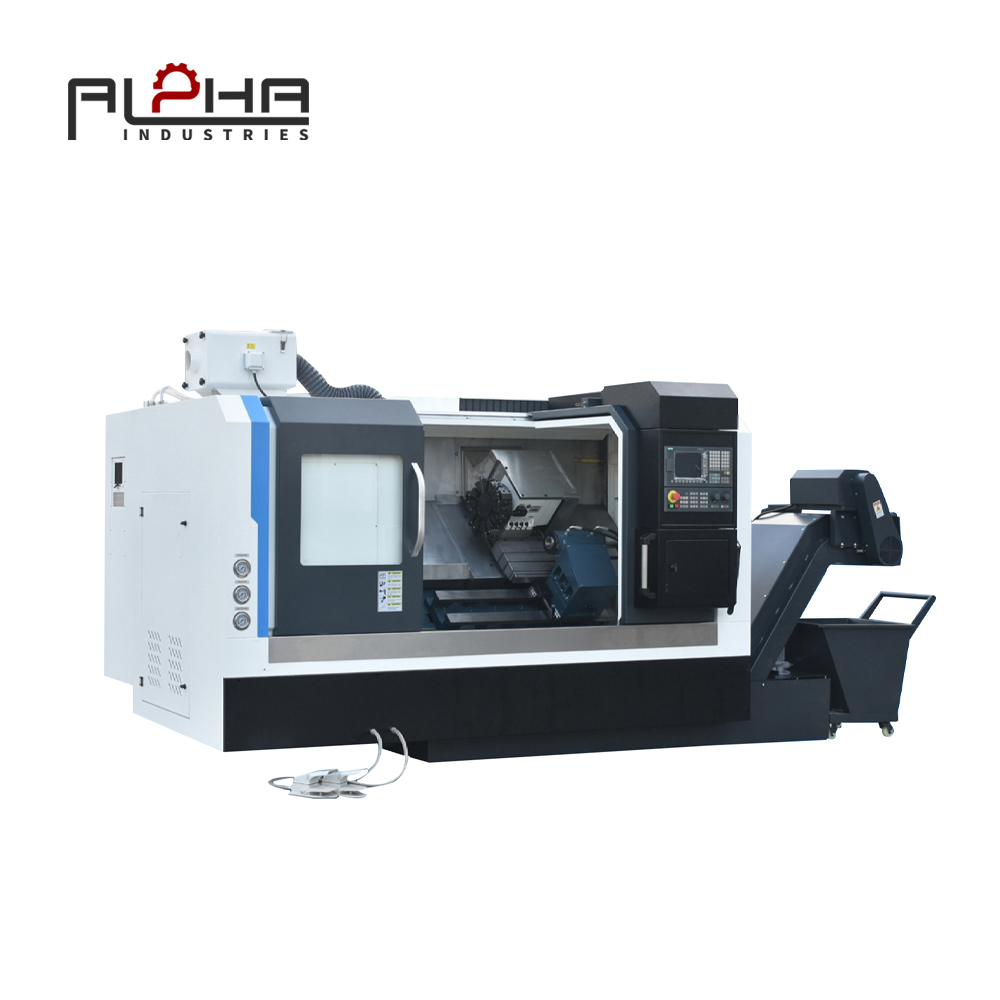

The slant bed structure in a CNC lathe is engineered to offer superior rigidity, chip control, and cutting accuracy—features crucial in high-precision turning applications. ALPHA’s CNC Lathe Slant Bed is specifically designed for industries requiring consistent surface finish and tight dimensional tolerance, such as aerospace, automotive, and general precision engineering.

Structural Advantages of Slant Bed CNC Lathe

Slant bed design provides a natural advantage in structural rigidity and thermal stability. The inclined carriage reduces the span between tool post and guideways, minimizing vibration and deflection during heavy cutting. The one-piece heavy-duty casting is internally ribbed to resist torsional distortion, ensuring the machine maintains accuracy under load.

The angled bed also improves the distribution of cutting forces, offering better dynamic rigidity for operations involving high cutting forces, such as deep grooving or heavy-duty roughing.

Optimal Chip Evacuation for Uninterrupted Machining

One of the significant benefits of a slant bed is its gravity-assisted chip evacuation. Chips fall naturally away from the cutting zone, reducing the chance of recutting and preventing thermal buildup on the part or tooling. ALPHA’s machine integrates an automatic chip conveyor system, which complements the slant structure to ensure clean and efficient operation over long runs.

Integrated Turret and Spindle System for Versatile Machining

Equipped with a high-torque spindle and servo-indexing turret, the CNC Lathe Slant Bed can support multiple operations without repositioning the workpiece. The turret’s rapid indexing and rigid locking mechanism reduce tool change time and maintain consistent tool alignment.

The spindle features high concentricity and is supported by precision bearings to maintain roundness during turning. A dual-range gearbox or belt drive configuration is used depending on the torque-speed requirement, suitable for shaft, flange, and complex contour turning.

Control System and Automation Interface

ALPHA integrates intuitive, customizable CNC controllers with support for G-code programming, automatic tool compensation, and remote monitoring. Options for bar feeders, tailstocks, parts catchers, and robotic loading interfaces are available, making the slant bed CNC lathe compatible with Industry 4.0 smart manufacturing environments.

Common Applications Across Industries

The CNC Lathe Slant Bed is ideal for:

-

High-precision shaft machining

-

Thread cutting and contouring

-

Production of cylindrical components

-

Fine-finishing operations in small to medium batches

ALPHA’s machine is used in sectors demanding accuracy, such as:

-

Automotive powertrain manufacturing

-

Aerospace component machining

-

Hydraulic cylinder turning

-

Industrial equipment shaft production

Built for Durability and Accuracy

Key design elements for consistent performance include:

-

Hardened and precision-ground linear guideways

-

Direct drive or belt-driven spindle with thermal compensation

-

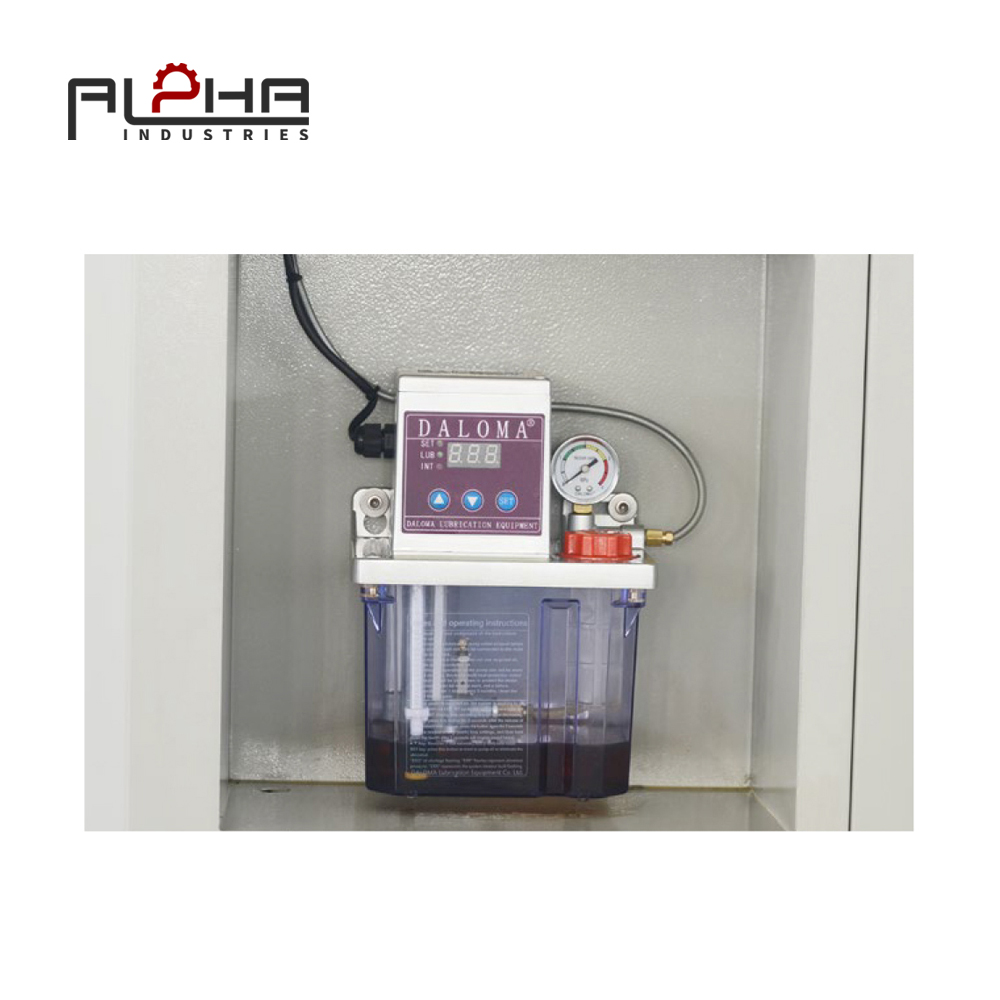

Automatic lubrication for all moving axes

-

Enclosed guarding for operator safety and coolant control

Every ALPHA machine undergoes dynamic testing, precision alignment, and electronic compensation for pitch error and backlash to meet strict tolerances.

FAQs

What is the advantage of using a slant bed in CNC lathes?

The slant bed increases rigidity, enhances chip removal, and reduces vibration, making it ideal for high-precision and high-speed machining.

Is a CNC Lathe Slant Bed suitable for long shaft machining?

Yes. The inclined structure ensures straight-line rigidity and better support for tailstock or steady rest integration, which is critical for long workpieces.

How does the slant bed design affect tool life?

By reducing vibration and improving chip evacuation, the slant bed reduces tool wear and maintains consistent cutting performance, extending tool life.

Can CNC Lathe Slant Beds handle interrupted cutting?

Yes. The stable bed structure and reinforced turret system make the machine capable of interrupted or heavy cuts without losing positioning accuracy.

What kind of materials can be machined with a slant bed lathe?

This type of lathe is suitable for a wide range of materials including carbon steel, stainless steel, cast iron, aluminum, and various alloys used in precision industries.