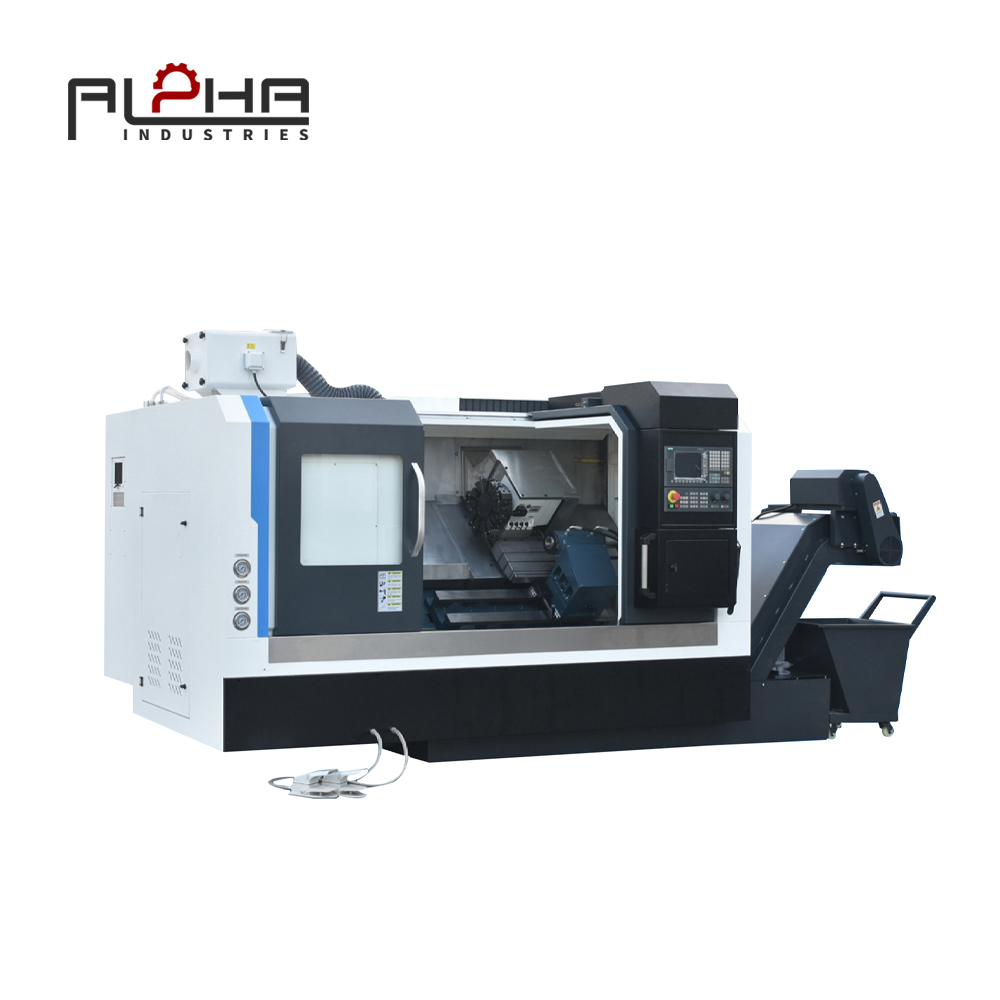

CNC LATHE SLANT Overview: Engineered for Thermal Stability

The CNC LATHE SLANT is a high-rigidity metal turning solution engineered specifically to solve one of the most critical problems in precision machining—thermal deformation. During continuous high-load cutting, heat accumulation directly affects dimensional accuracy, tool life, and surface consistency. Alpha’s Slant Bed CNC Lathe is structurally optimized to maintain stable geometry even under extreme thermal loads, ensuring micron-level precision over long production cycles.

Unlike flat-bed lathes, the slanted design naturally enhances heat dissipation, gravity-assisted chip evacuation, and structural symmetry, making it the preferred choice for automotive parts, shafts, hydraulic components, and aerospace fittings.

Why Thermal Stability Is Critical in CNC Turning

Thermal deformation is responsible for over 65% of precision drift in long-cycle CNC turning operations. As spindle speed increases, friction and cutting resistance generate continuous heat, causing:

-

Spindle axial expansion

-

Bed structural distortion

-

Tool center height deviation

-

Repeated dimensional drift

-

Surface roughness inconsistency

A thermally unstable CNC lathe directly increases scrap rates and rework cost. Therefore, modern high-end production lines demand thermally compensated CNC LATHE SLANT systems.

Slant Bed Structure: The Core of Thermal Control

The 45° or 30° slant bed angle in Alpha’s CNC LATHE SLANT creates three direct thermal advantages:

Uniform Heat Distribution

The inclined bed distributes internal thermal stress evenly, preventing localized distortion.

Natural Convection Cooling

The slanted geometry accelerates air circulation around the bed and spindle casting.

Lower Thermal Gradient

Heat migrates downward rather than accumulating near spindle bearings.

This results in stable spindle alignment even during 24/7 operations.

High-Rigidity Cast Iron Bed for Heat Resistance

Alpha’s Slant Bed CNC Lathe uses high-density Meehanite cast iron, stress-relieved through triple aging treatment. This provides:

-

Low thermal expansion coefficient

-

High vibration damping

-

Long-term dimensional stability

-

Resistance to seasonal temperature variation

This bed structure ensures that machine geometry remains unchanged even after years of heavy-duty cutting.

Spindle Thermal Compensation System

Alpha CNC LATHE SLANT integrates:

-

Spindle temperature sensors

-

Real-time thermal compensation algorithms

-

Dynamic servo correction

This allows the control system to automatically adjust the tool position based on spindle heat expansion, ensuring:

-

Stable axial positioning

-

Consistent bore accuracy

-

Repeatable turning tolerances within ±0.003 mm

Chip Evacuation & Heat Dissipation Synergy

Efficient chip removal is essential for thermal stability. The slanted bed CNC lathe automatically utilizes gravity-assisted chip flow, which:

-

Prevents chip accumulation on guideways

-

Eliminates secondary heat concentration

-

Protects linear rails from thermal contamination

-

Extends lubrication film stability

This design directly improves machine longevity and positioning accuracy.

Guideway & Ball Screw Thermal Isolation

Alpha applies thermal isolation chambers between:

-

Ball screw & bed casting

-

Linear guide blocks & base structure

This prevents heat transfer from rapid feed movements into the machine framework, maintaining feed accuracy under high-speed positioning.

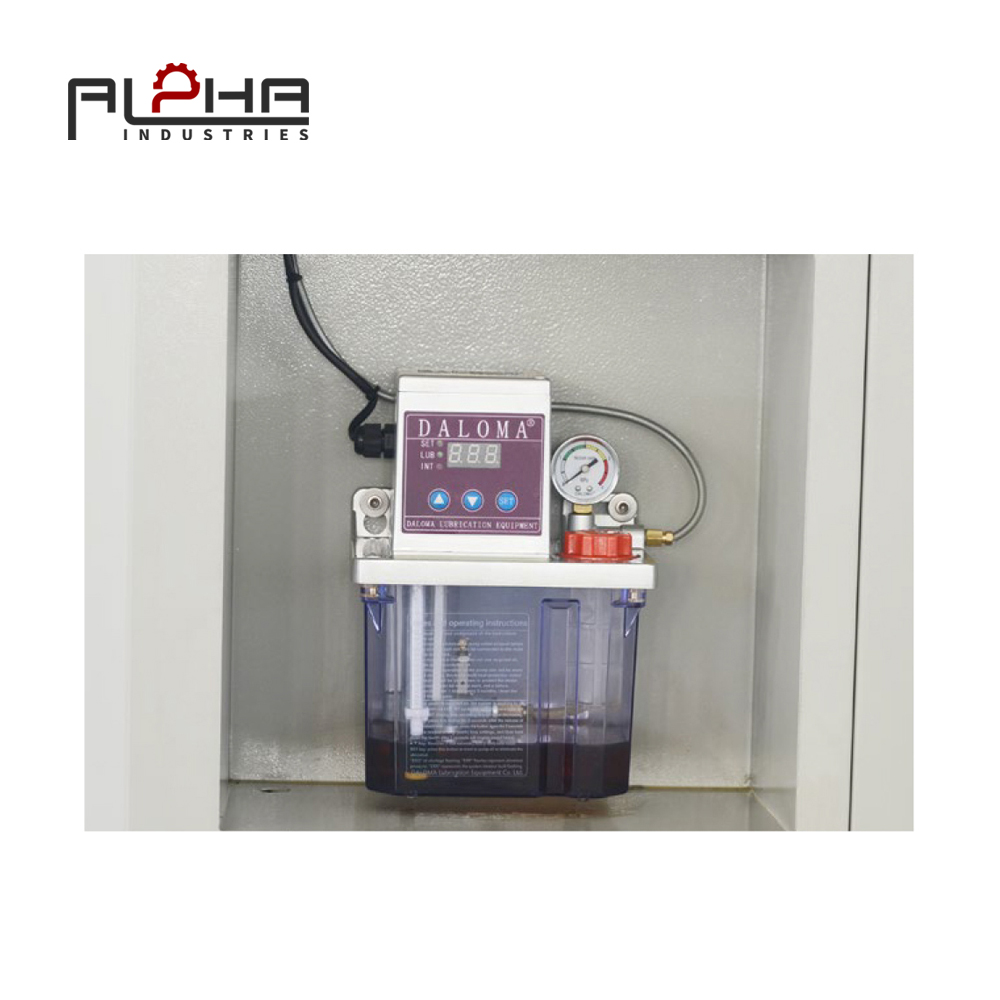

Cooling System Design for Long-Cycle Accuracy

Alpha CNC LATHE SLANT is equipped with:

-

Independent spindle oil cooling

-

Servo motor cooling circuits

-

Enclosed coolant circulation tank with temperature stabilization

This fully integrated cooling architecture prevents thermal accumulation during:

-

High-RPM finishing cycles

-

Heavy rough turning

-

Continuous multi-shift production

Thermal Stability Impact on Cutting Accuracy

With stable thermal control, Alpha CNC LATHE SLANT delivers:

-

Constant tool nose radius positioning

-

Stable surface roughness (Ra ≤ 1.6 μm)

-

Consistent roundness and cylindricity

-

Reduced tool offset recalibration frequency by 60%

This directly increases production yield and process automation reliability.

Application Scenarios Requiring High Thermal Stability

Industries that demand thermally stable CNC LATHE SLANT systems include:

-

Automotive transmission shafts

-

Precision hydraulic cylinders

-

Aerospace fasteners

-

Medical stainless steel components

-

High-speed motor shafts

-

Oil & gas valve cores

In these sectors, thermal drift tolerance is below 5 microns, making slant bed technology essential.

CNC LATHE SLANT vs Flat Bed: Thermal Comparison

| Feature | Slant Bed CNC Lathe | Flat Bed CNC Lathe |

|---|---|---|

| Heat Dissipation | Excellent | Moderate |

| Chip Accumulation | Minimal | High |

| Thermal Deformation | Very Low | Moderate |

| Continuous Stability | High | Medium |

| Precision Retention | Long-term | Short-term |

This confirms that slant bed CNC lathes are structurally superior for thermal-sensitive precision turning.

Product Quality & Process Control at Alpha

Every Alpha CNC LATHE SLANT undergoes:

-

72-hour continuous thermal drift testing

-

Spindle heat rise verification

-

Laser interferometer geometry calibration

-

Load-based thermal displacement simulation

This ensures each machine meets international precision stability standards before shipment.

FAQ

Q1: What makes CNC LATHE SLANT more thermally stable than flat bed lathes?

The slanted bed structure improves heat distribution, chip evacuation, and natural cooling, reducing localized thermal deformation.

Q2: Does spindle heat affect turning accuracy?

Yes. Spindle heat causes axial expansion, which shifts tool position. Alpha machines use real-time thermal compensation.

Q3: Can CNC LATHE SLANT maintain accuracy in 24-hour production?

Yes. With integrated cooling and thermal isolation, dimensional drift is minimized even under continuous operation.

Q4: How often does the tool offset need recalibration?

On thermally stable systems, offset recalibration frequency is reduced by over 60%.

Q5: Is thermal stability important for hard material turning?

Absolutely. Hard materials generate higher cutting temperatures, making thermal stability essential for precision.

If your production requires long-term precision, heavy-duty cutting, and zero thermal drift, Alpha’s CNC LATHE SLANT is engineered to exceed industrial accuracy standards.

👉 Explore More Alpha Metal Machines:

-

Vertical Machining Center – High-speed precision milling

-

Press Brake Machine – Sheet metal bending automation

-

Drilling & Milling Machine – Multi-process machining solution

-

Surface Grinder – Ultra-fine finishing system

-

Laser Cutting Machine – High-speed sheet processing system