Why Crowning Is Critical in CNC Press Brake Accuracy

In sheet metal bending, achieving a consistent angle along the entire bend length is one of the most difficult challenges.

Even with a rigid frame and precise control system, machine deflection under load is unavoidable.

This is where the automatic crowning system becomes a core technology in modern CNC Press Brake design.

For manufacturers demanding high accuracy, repeatability, and long-term stability, an advanced crowning system is no longer optional—it is essential.

This article focuses on one key performance factor:

👉 How CNC Press Brake automatic crowning systems work, why they matter, and how they improve real production accuracy.

What Is Deflection in CNC Press Brake Bending?

During bending, the press brake applies massive force along the worktable and ram.

As tonnage increases, the machine frame and bed experience elastic deformation, commonly known as deflection.

Effects of deflection:

-

Middle section bends deeper than both ends

-

Inconsistent bend angles along the length

-

Higher scrap and rework rates

Without compensation, even a high-end CNC Press Brake cannot guarantee uniform bending across long parts.

What Is an Automatic Crowning System?

An automatic crowning system is a controlled compensation mechanism designed to counteract machine deflection during bending.

Instead of allowing the bed to deform naturally, the crowning system introduces a controlled counter-deformation, ensuring the ram applies equal pressure across the entire length.

In CNC Press Brakes, crowning is managed by:

-

CNC-controlled mechanical wedges, or

-

Servo-driven hydraulic compensation units

Both systems are dynamically adjusted based on bending force and material parameters.

4. Manual Crowning vs Automatic Crowning

| Feature | Manual Crowning | Automatic Crowning |

|---|---|---|

| Adjustment method | Hand-operated | CNC-controlled |

| Accuracy | Limited | High |

| Setup time | Long | Short |

| Repeatability | Low | Excellent |

| Suitability | Simple jobs | Precision production |

Automatic crowning allows the CNC Press Brake to adapt instantly to different materials, thicknesses, and bend lengths—without operator intervention.

How CNC Press Brake Automatic Crowning Works

Step-by-step process:

-

Operator inputs material thickness, length, and tooling data

-

CNC system calculates expected deflection

-

Crowning system applies calculated counter-force

-

Compensation adjusts dynamically during bending

This closed-loop control ensures uniform angle accuracy, even under varying load conditions.

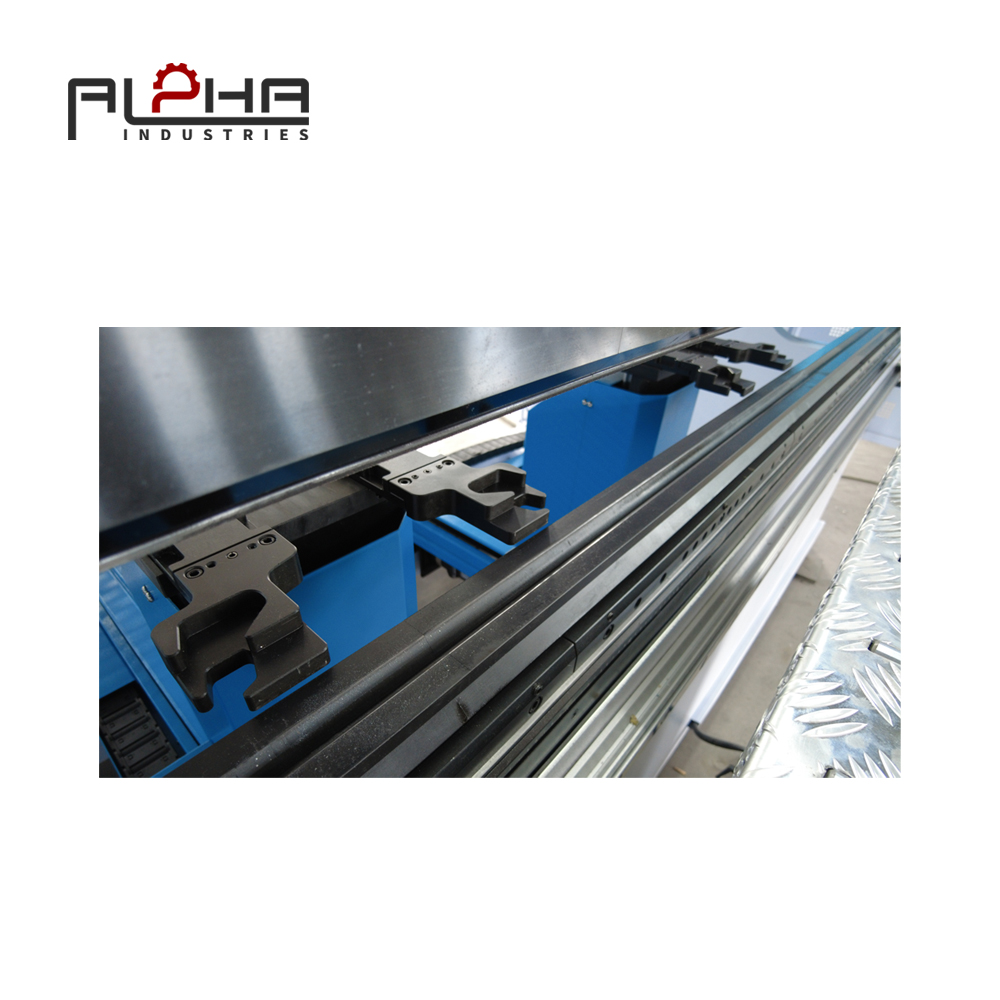

Mechanical Crowning Systems: Structure and Advantages

Mechanical crowning systems typically use:

-

Precision-ground wedges

-

CNC-controlled adjustment motors

-

High-strength steel components

Advantages:

-

Stable and durable structure

-

High positioning accuracy

-

Minimal maintenance

Mechanical crowning is widely used in heavy-duty CNC Press Brakes due to its reliability and long service life.

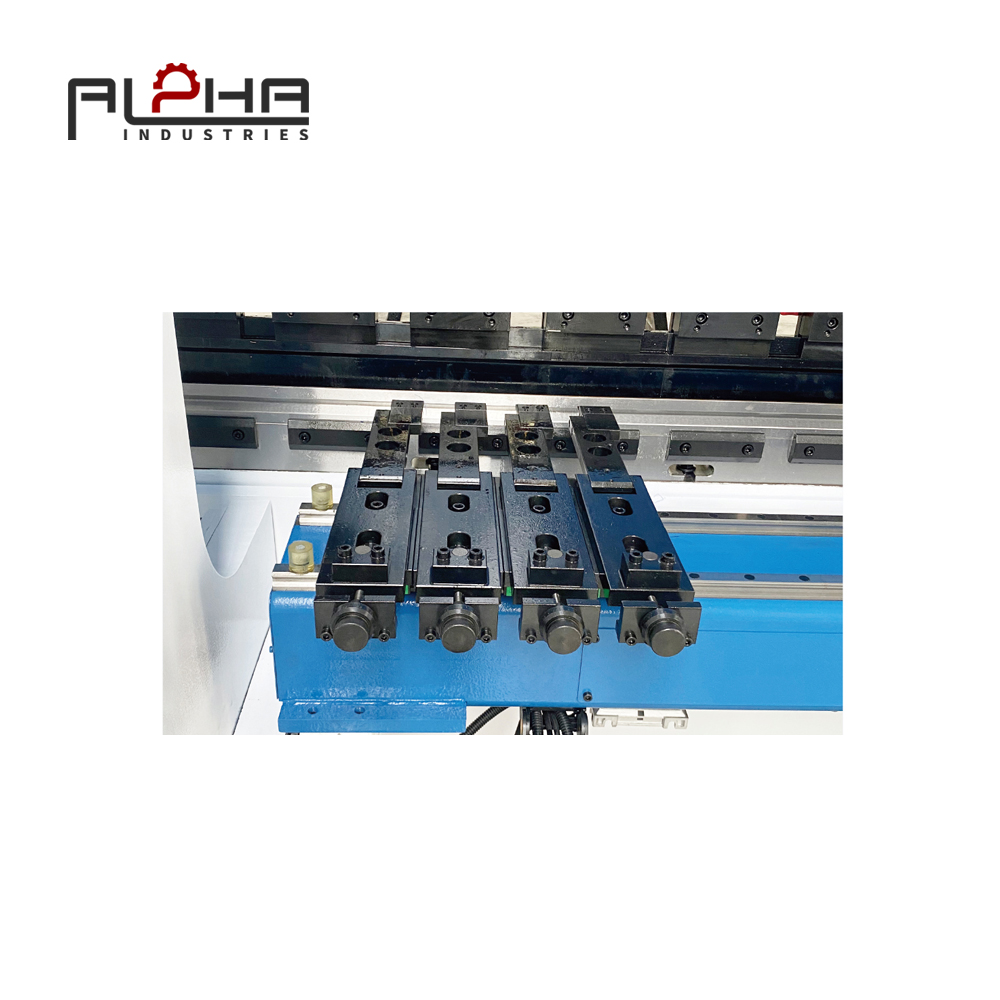

Hydraulic Crowning Systems: Dynamic Compensation

Hydraulic crowning systems use:

-

Multiple hydraulic cylinders

-

Pressure sensors

-

CNC-controlled proportional valves

Advantages:

-

Real-time dynamic adjustment

-

Excellent response to load changes

-

Ideal for variable thickness production

This system is especially effective for high-mix, low-volume manufacturing environments.

How Automatic Crowning Improves Bending Accuracy

Automatic crowning directly improves:

-

Full-length angle consistency

-

Dimensional stability

-

Surface quality

With proper crowning:

-

Angle deviation is reduced significantly

-

First-piece accuracy improves

-

Rework is minimized

For precision parts, crowning accuracy often determines final product acceptance.

Impact on Production Efficiency and Cost

Beyond quality, automatic crowning improves operational efficiency.

Key benefits:

-

Faster setup times

-

Less trial bending

-

Reduced scrap material

-

Lower operator skill dependency

Over time, a CNC Press Brake with automatic crowning delivers lower cost per part.

Key Crowning Parameters Buyers Should Evaluate

When selecting a CNC Press Brake, buyers should examine:

-

Crowning adjustment range

-

Control resolution

-

Response speed

-

Integration with CNC system

A well-designed crowning system must match the machine’s tonnage and working length.

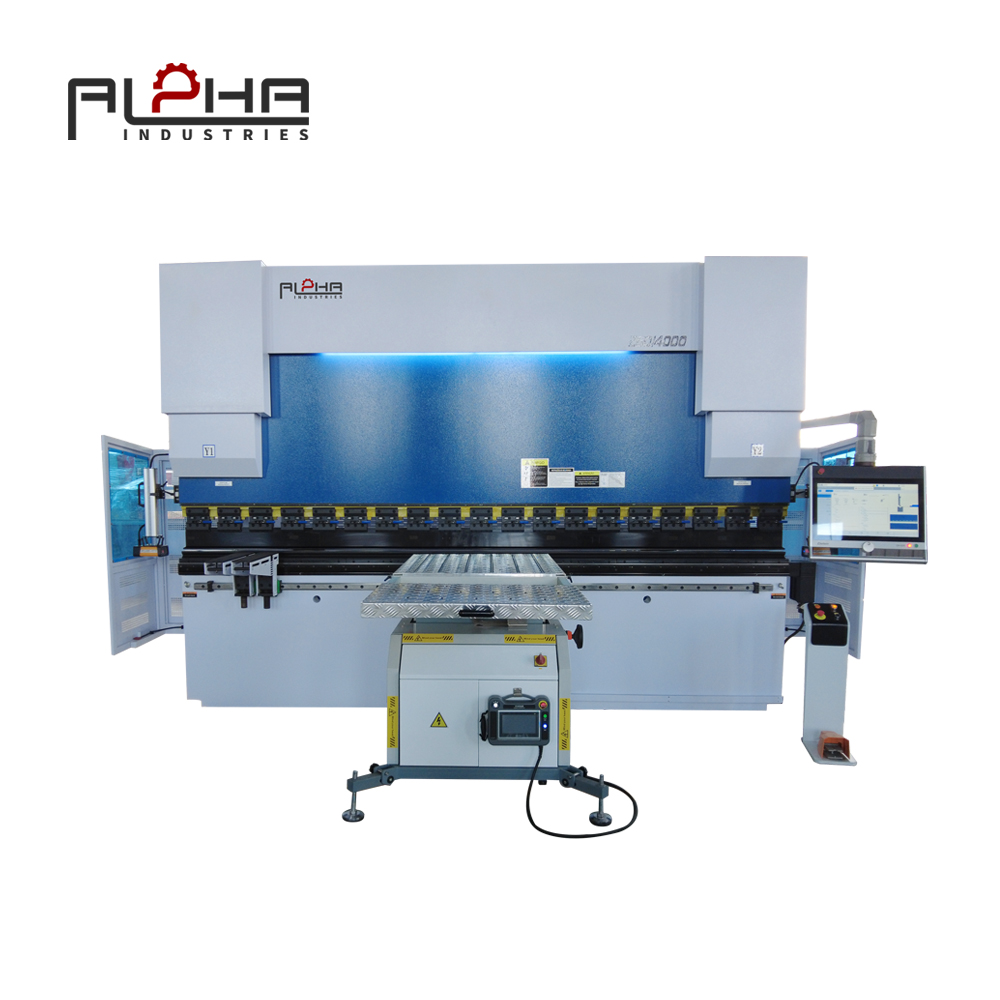

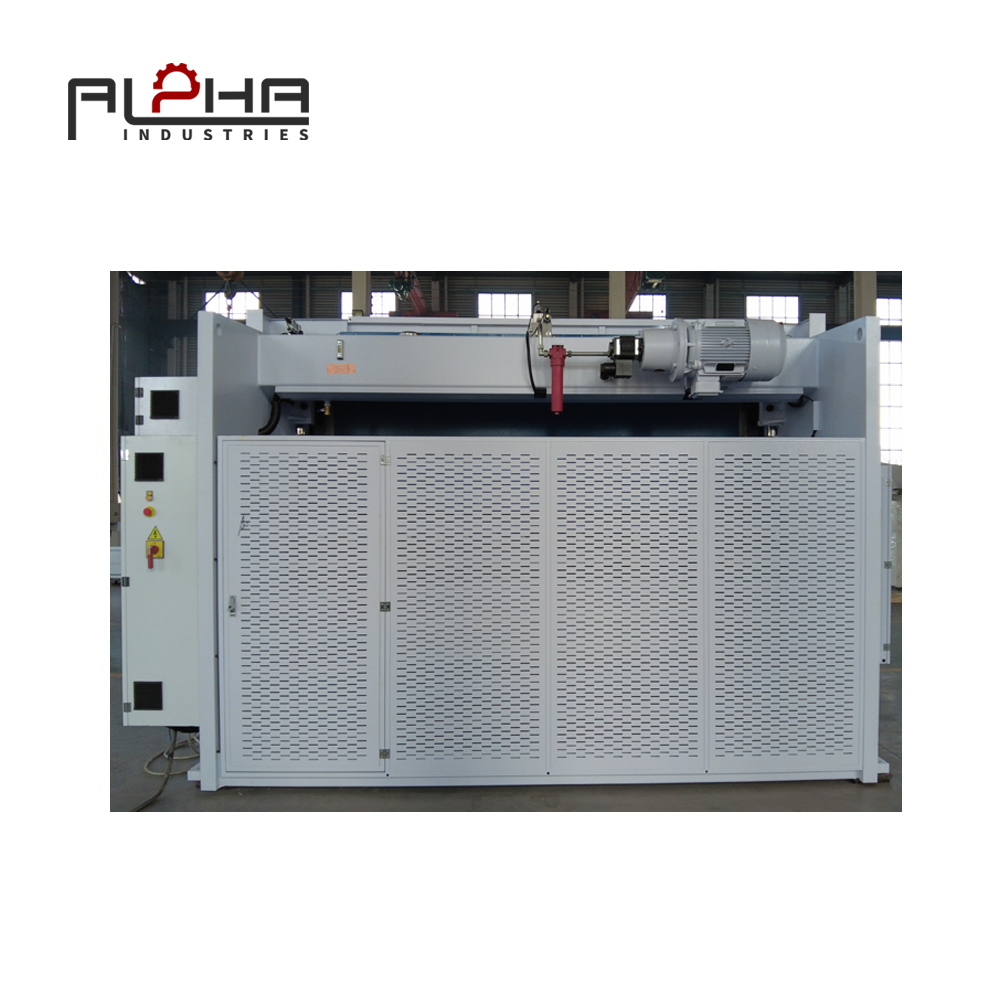

Alpha CNC Press Brake Crowning Technology

At Alpha, CNC Press Brakes are designed with integrated automatic crowning systems to ensure long-term accuracy.

Key design highlights:

-

High-rigidity frame structures

-

CNC-synchronized crowning control

-

Precision-machined crowning components

-

Stable performance under continuous load

This ensures consistent bending accuracy across diverse production scenarios.

Typical Applications Requiring Automatic Crowning

Automatic crowning is critical in:

-

Electrical cabinets

-

Sheet metal enclosures

-

Elevator panels

-

Long structural components

-

Precision industrial housings

In these applications, angle deviation across length is unacceptable.

FAQ

Q1: What does crowning do on a CNC Press Brake?

Crowning compensates machine deflection to ensure uniform bending angle across the entire workpiece length.

Q2: Is automatic crowning necessary for all CNC Press Brakes?

It is essential for long parts, thick materials, and high-precision applications.

Q3: Can automatic crowning adjust during bending?

Yes. CNC-controlled systems adjust compensation dynamically based on load conditions.

Q4: Does crowning reduce operator adjustment?

Yes. Automatic crowning significantly reduces manual correction and trial bending.

Automatic Crowning Defines Precision CNC Press Brakes

Automatic crowning is a defining feature of high-performance CNC Press Brakes.

By compensating deflection in real time, it ensures consistent accuracy, higher efficiency, and reliable bending quality.

For manufacturers seeking precision and productivity, a CNC Press Brake with advanced automatic crowning is a long-term competitive advantage.

👉 Learn more about Alpha CNC Press Brake solutions:

https://alpha-cnc.com/