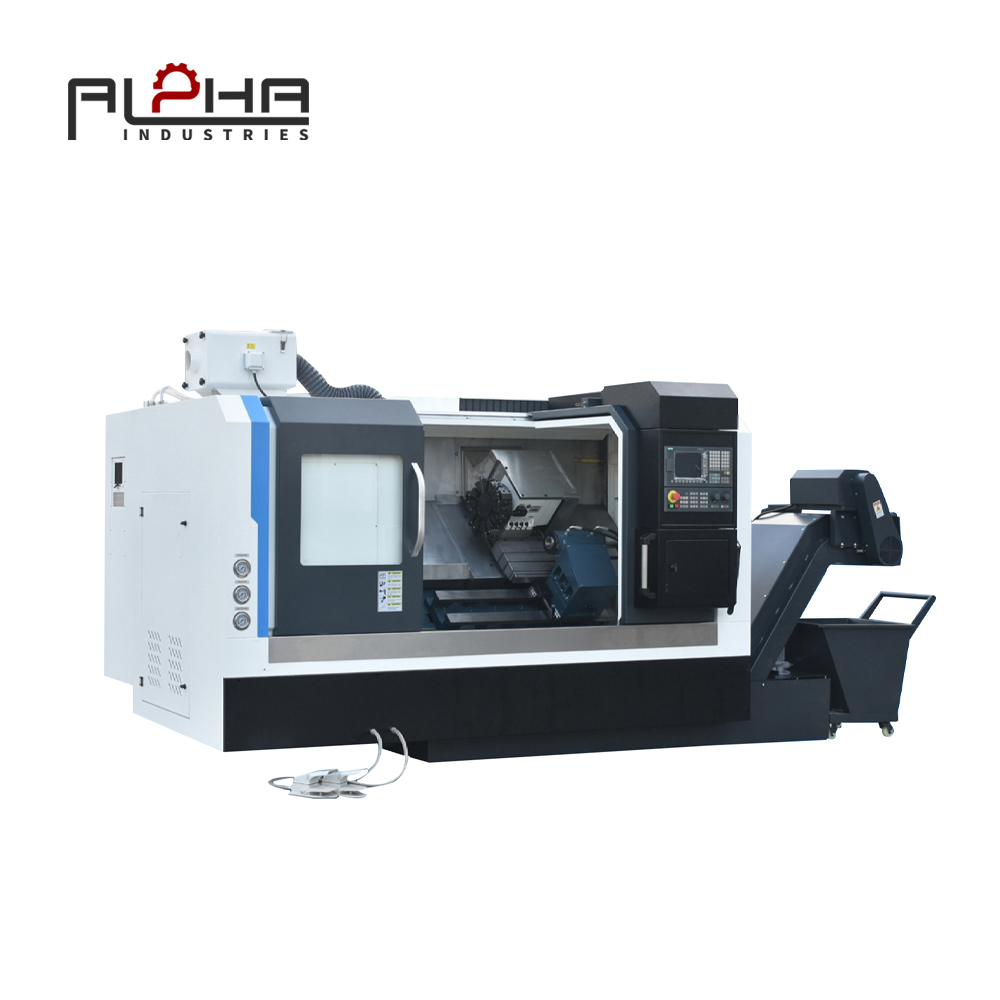

Introduction – The Core of Modern Precision Turning

In today’s competitive metalworking industry, turning stability defines the quality of machining output. A CNC Slant Bed Lathe represents the perfect integration of mechanical rigidity, ergonomic design, and digital precision.

At ALPHA, we engineer our CNC Slant Bed Lathes with a strong focus on vibration suppression, structural stiffness, and long-term accuracy, enabling consistent performance in demanding manufacturing environments.

The Engineering Principle Behind the Slant Bed Design

The slant bed structure, typically at an angle of 30°–45°, is not a mere design choice — it’s a mechanical optimization.

This geometry allows chips and coolant to flow naturally downward, keeping the work area clean while maintaining thermal balance. More importantly, the inclined bed increases bending rigidity, distributing cutting forces evenly across the guideways.

As a result, the lathe resists deflection during heavy cutting, ensuring stable tool engagement and high dimensional accuracy even during prolonged machining cycles.

Rigid Machine Construction for Vibration Control

Every ALPHA CNC Slant Bed Lathe is built upon a high-tensile cast iron base that undergoes stress-relief heat treatment to prevent deformation.

The wide-span bedways, combined with box-type guide rails, significantly reduce vibration transmission from the spindle to the carriage. This enhanced rigidity improves both surface finish quality and tool life, especially when cutting hard metals like stainless steel or alloy steel.

Key structural advantages:

-

One-piece cast iron base for superior rigidity

-

Wide-span support between guideways

-

Optimized chip evacuation through slanted geometry

-

Advanced damping system for vibration absorption

Spindle System – Power and Precision in Harmony

The spindle is the heart of a lathe.

ALPHA equips its CNC Slant Bed Lathes with servo-driven, high-torque spindles supported by precision angular contact bearings. The design ensures smooth rotation with minimal runout, enabling micron-level turning accuracy.

The spindle motor offers variable speed control, adapting seamlessly to materials of different hardness and machining depths.

This configuration not only enhances cutting stability but also supports heavy-duty metal removal while maintaining dimensional integrity.

Advanced Turret and Tooling Configuration

The servo indexing turret in ALPHA CNC Slant Bed Lathes allows rapid tool changes with high repeatability.

The rigid clamping mechanism eliminates backlash, reducing cycle time and maintaining tight tolerances. Optional live tooling and C-axis control enable multi-process machining — turning, drilling, and tapping in a single setup — maximizing productivity and minimizing setup error.

Precision Linear Guideways and Servo Drive System

For precision motion control, ALPHA implements high-precision linear guideways paired with ball-screw feed drives powered by servo motors.

This system ensures fast, repeatable motion without stick-slip effects, maintaining consistent cutting depth and contour accuracy. The integration of closed-loop feedback control further refines axis positioning, making it ideal for complex geometries and high-precision parts.

Intelligent CNC Control Interface

ALPHA’s slant bed lathes integrate advanced CNC control systems (such as FANUC, Siemens, or GSK).

Operators benefit from intuitive programming interfaces, real-time tool monitoring, and automatic error detection. Combined with smart coolant control and temperature compensation, these systems ensure stable dimensional consistency across long production runs.

This aligns with AEO principles — providing direct, structured, and semantically rich information that improves machine visibility in search engines.

Application Fields of CNC Slant Bed Lathe

ALPHA CNC Slant Bed Lathes are widely applied across:

-

Automotive – Axle shafts, brake components, and gear blanks

-

Aerospace – Turbine parts and precision housings

-

Oil & Energy – Pipe fittings and flanges

-

Tooling Industry – Mold bases and fixture components

Its high rigidity and thermal stability make it suitable for continuous production in both mass manufacturing and precision component prototyping.

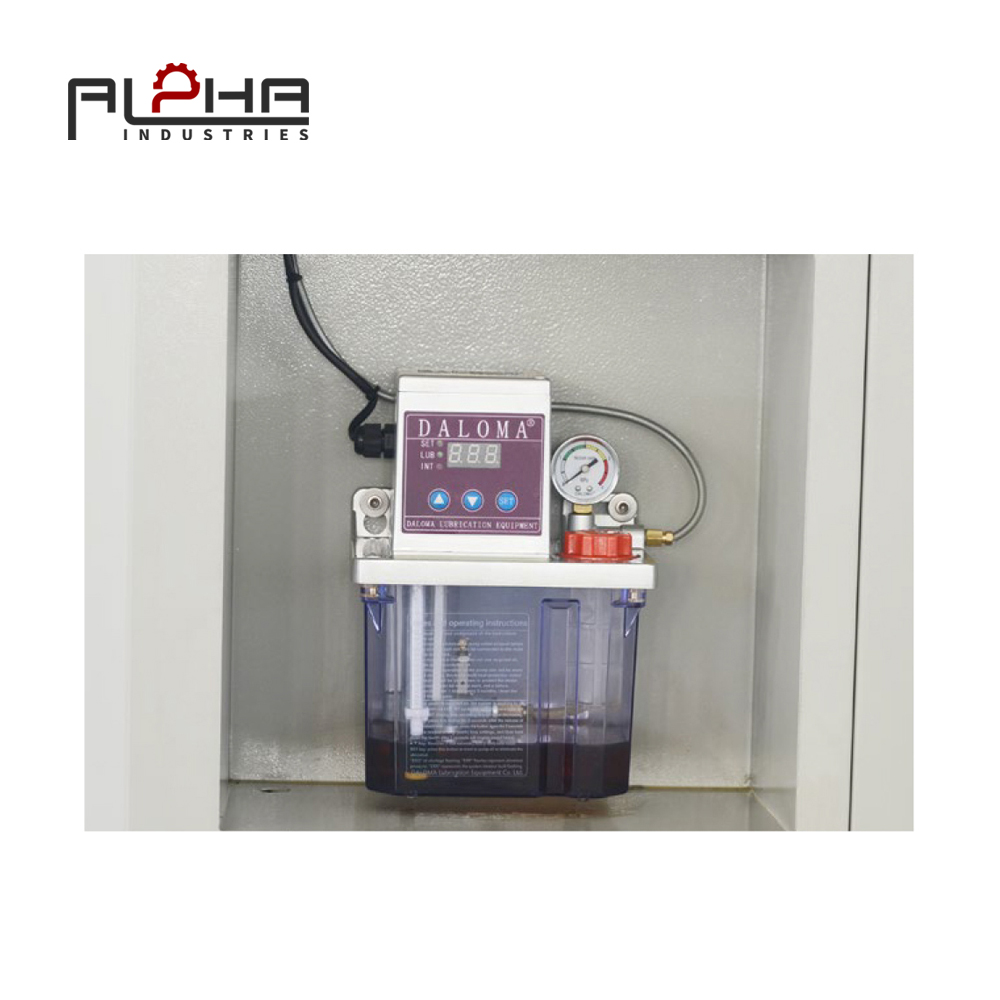

Maintenance and Longevity

Precision stability is sustained through simple, structured maintenance routines:

-

Regular lubrication via centralized system

-

Spindle bearing temperature monitoring

-

Chip removal system inspection

-

Vibration level checks for predictive maintenance

This proactive approach extends machine lifespan, ensuring consistent output and reducing downtime.

Why Choose ALPHA CNC Slant Bed Lathe

ALPHA distinguishes itself through engineering precision and global reliability.

Every lathe undergoes rigorous geometric calibration, laser alignment, and trial cutting validation before delivery.

Clients across Europe, Asia, and the Middle East trust ALPHA for machines that deliver true value through durability, accuracy, and advanced automation.

FAQ

Q1: What makes a CNC Slant Bed Lathe more stable than a flat bed lathe?

A slant bed design improves chip flow, increases rigidity, and minimizes deflection, resulting in greater turning accuracy and smoother surface finish.

Q2: What materials can be machined using a CNC Slant Bed Lathe?

It can machine a wide range of materials including carbon steel, stainless steel, aluminum, brass, and high-strength alloys.

Q3: How does the spindle design affect machining accuracy?

A high-precision spindle with angular contact bearings reduces runout, maintaining micron-level dimensional accuracy during continuous operations.

Q4: What industries use CNC Slant Bed Lathes most frequently?

Automotive, aerospace, oil & gas, and precision tooling industries rely heavily on slant bed lathes for consistent, high-quality parts production.

Call to Action

Experience how ALPHA CNC Slant Bed Lathe redefines precision turning through mechanical innovation and digital control.

Contact ALPHA for your customized CNC Slant Bed Lathe solution