Modern industrial landscapes are largely shaped by the capabilities of multi-purpose lathe machines (the cornerstone of manufacturing and manufacturing). From small workshops to large-scale production facilities, this equipment is crucial to shaping materials with incredible accuracy. With the development of technology, the evolution from manual lathe to complex CNC lathe models has completely changed what is possible, achieving complex geometry and unparalleled consistency. Achieve true precision machining starts with understanding the core components and operations of high-quality lathes.

Anatomy of high-performance lathe

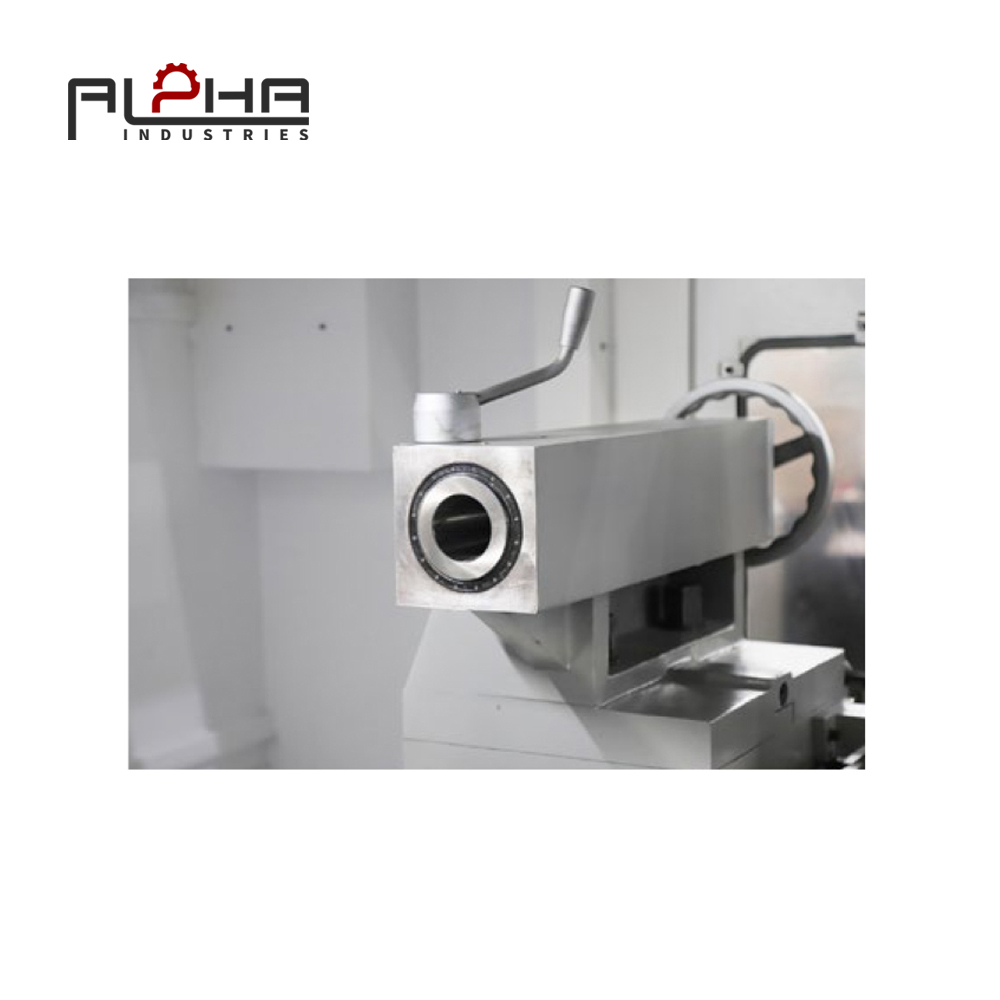

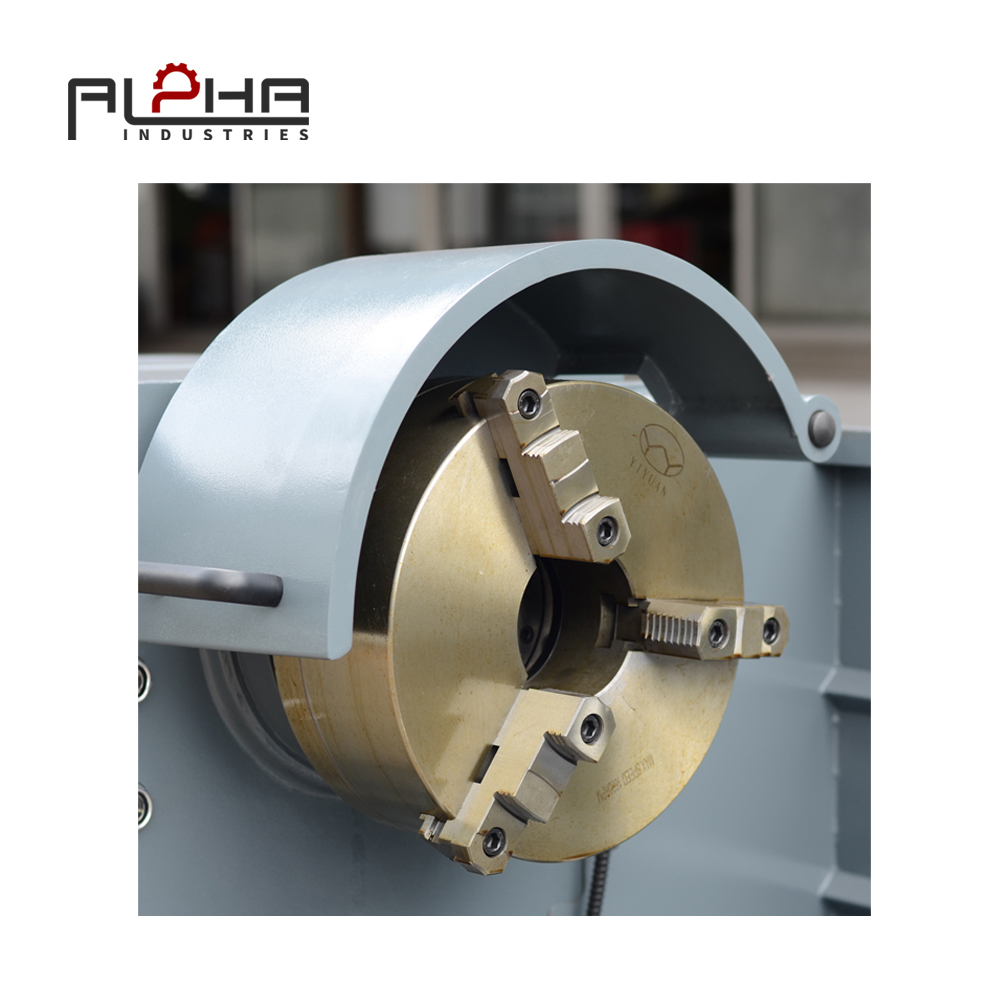

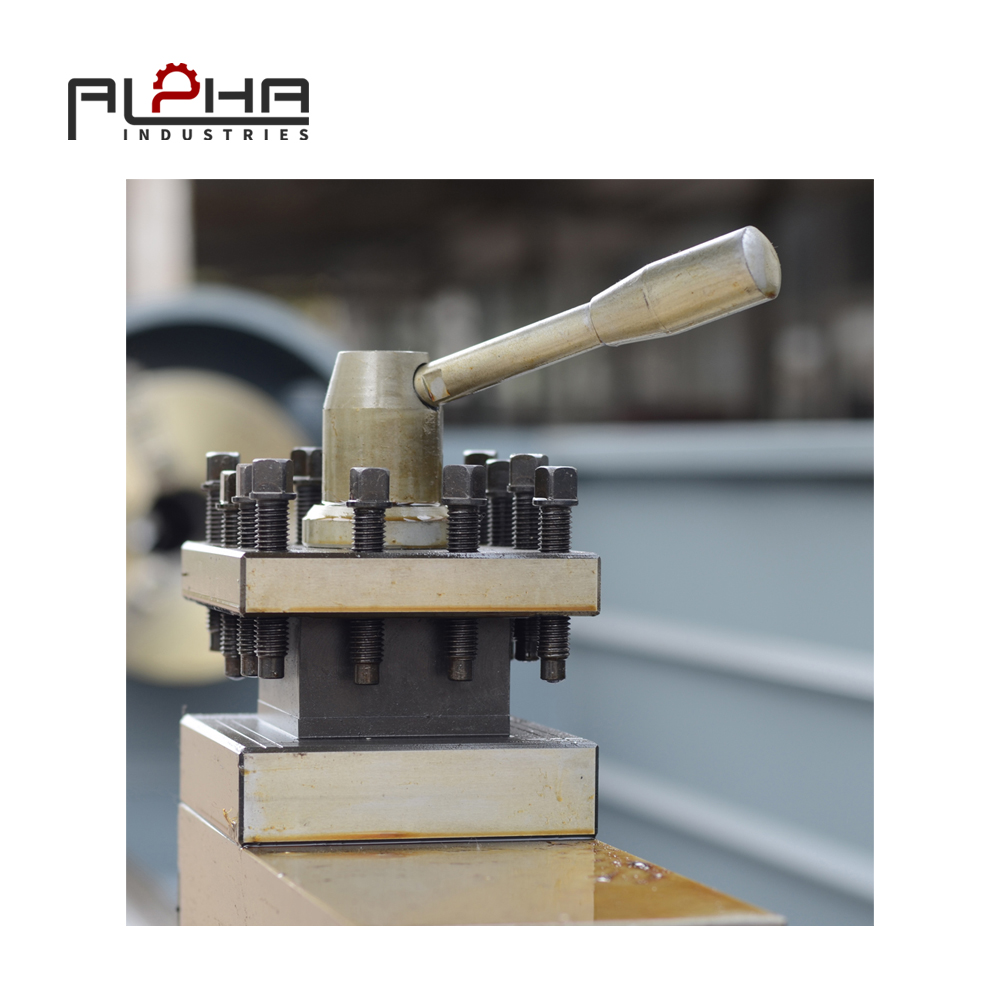

Advanced lathe machines are defined by the quality of their components and their robust structure. Critical lathe parts such as control dials, levers and measurement scales must be designed to ensure accuracy and durability. For example, carefully calibrated control dials and clear ratings allow technicians to make micron-scale adjustments, which is essential for high tolerance operations. Overall build quality is equally important; as found in Alpha's CR series, the sturdy industrial-grade frame resists vibration and wear, ensuring long-term operational stability. Functions such as advanced precision nozzles and heavy cylindrical interfaces further enhance the versatility of the machine, adapting it to a wide range of professional industrial processes.

Master lathe operation and tools

Effective lathe operation is a fusion of operator skills and machine capabilities. When the machine provides power and accuracy, the operator uses a variety of lathe tools to guide the process to cut, sand, nose, drill holes, or deform workpieces. The design of the machine can significantly affect this process. Ergonomic handbars and intuitively marked control switches minimize set time and reduce operator fatigue, resulting in higher productivity and fewer errors. Smooth and responsive lathe operation allows craftsmen to convert their vision into finished products with confidence, whether it is making complex components or handling heavy tasks. The right tools combined with a well-designed machine enable a perfect finish.

Find the right partner: not just lathe supplier

When investing in critical equipment, choosing from many available lathe suppliers is a crucial decision, which goes beyond the initial purchase. The best partners are not only machine sellers; they are solutions providers. Companies like Nanjing Alpha CNC Co., Ltd embody this philosophy by providing customers with everything from choosing a machine to designing a complete production line. Suppliers of professional R&D teams can provide world-class design and manufacturing capabilities to ensure that the equipment meets your business-specific needs. This partnership is especially important when upgrading to a modern CNC lathe, as it often requires integrated support and expert guidance to maximize your ROI.

Improve production through the right choice

Ultimately, the right lathe machine is a powerful asset that improves your production capacity, improves efficiency and ensures the highest quality of your product. By focusing on advanced lathe parts, user-friendly operation, and supportive supplier relationships, you can gain a competitive advantage in the demanding world of precision machining. Investing in reliable, accurate machines from trusted providers like Alpha CNC is an investment in the future success and growth of your business, ensuring you have the technology and support you need for Excel.