The foundation of modern manufacturing

In the world of manufacturing and manufacturing, lathe machines are the cornerstone of innovation and precision. For centuries, this basic tool has been used to shape materials such as metal and wood with obvious precision and perform operations such as cutting, grinding, shaking, exercising, drilling and turning. This evolution of basic equipment directly reflects advances in industrial technology, leading to the highly complex and automated systems we see today. Achieve superior results on any workshop or production line start with understanding the capabilities and nuances of high-quality lathes, a tool that truly brings engineering design to life.

The evolution of automation: CNC lathe

Although manual lathes require skilled operators for each movement, the emergence of computer numerical control (CNC) lathes has revolutionized the industry. CNC lathes integrate a computer to automate the entire process, performing pre-programmed designs with perfect repetition and speed. This changes the precisely processed landscape, making complex geometry and tight tolerances easier to achieve than ever. Lathe operation becomes a problem with digital programming rather than constant manual intervention, which not only improves efficiency and output, but also greatly reduces the edge of human error. This leap in technology allows companies to consistently produce complex components, ensuring that each piece meets the exact specifications.

Excellent Anatomy: Key Lathe Parts and Tools

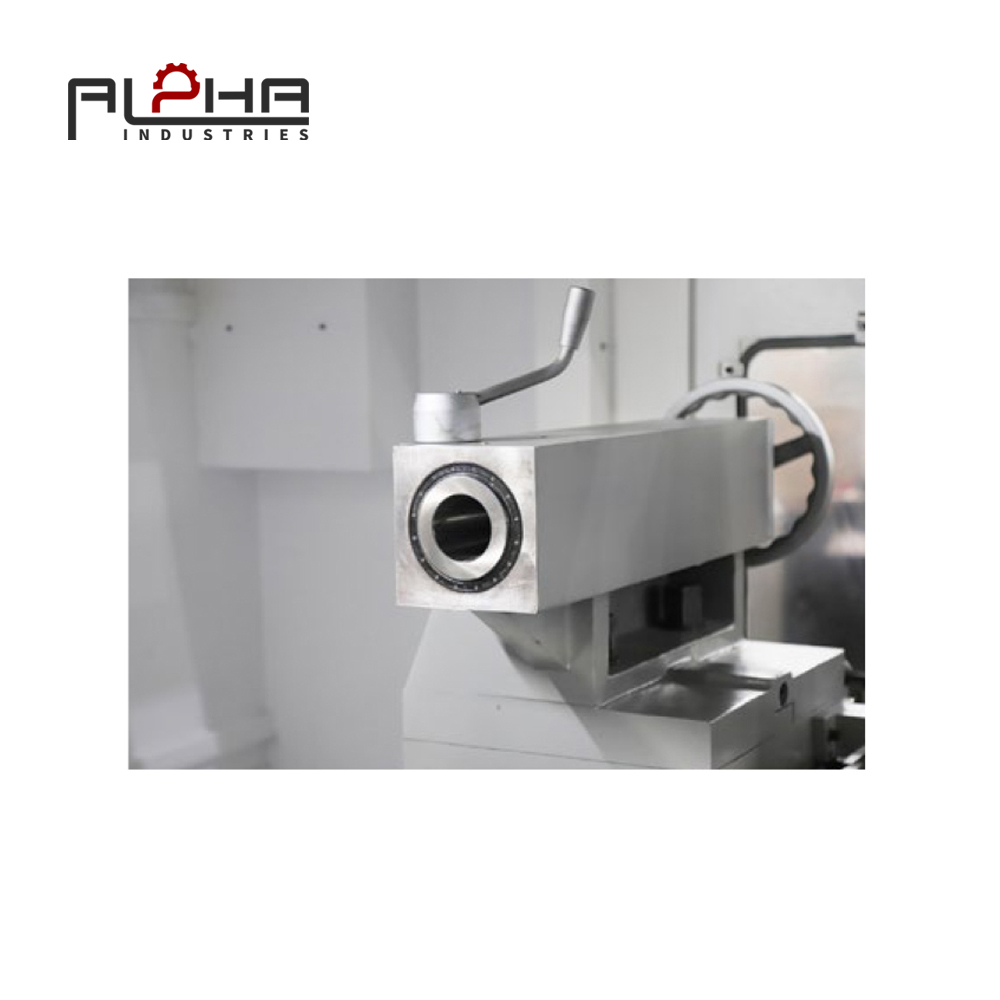

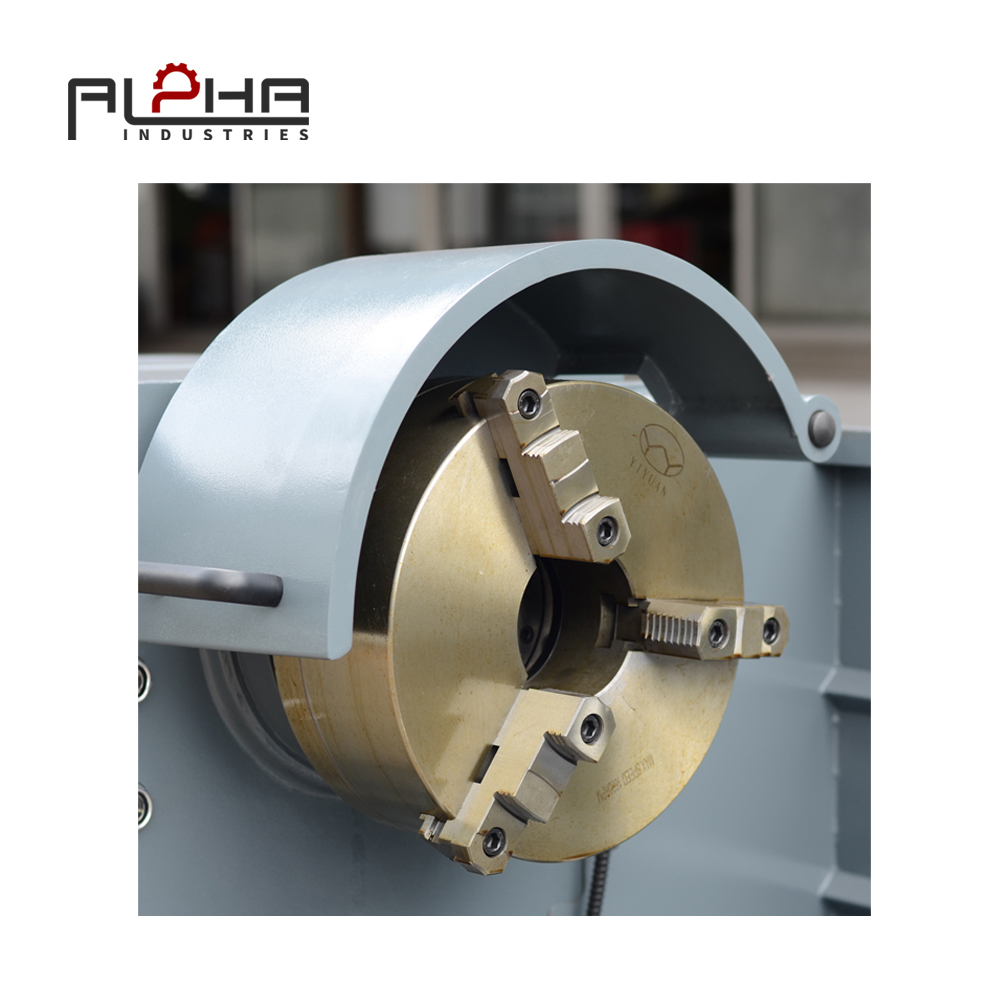

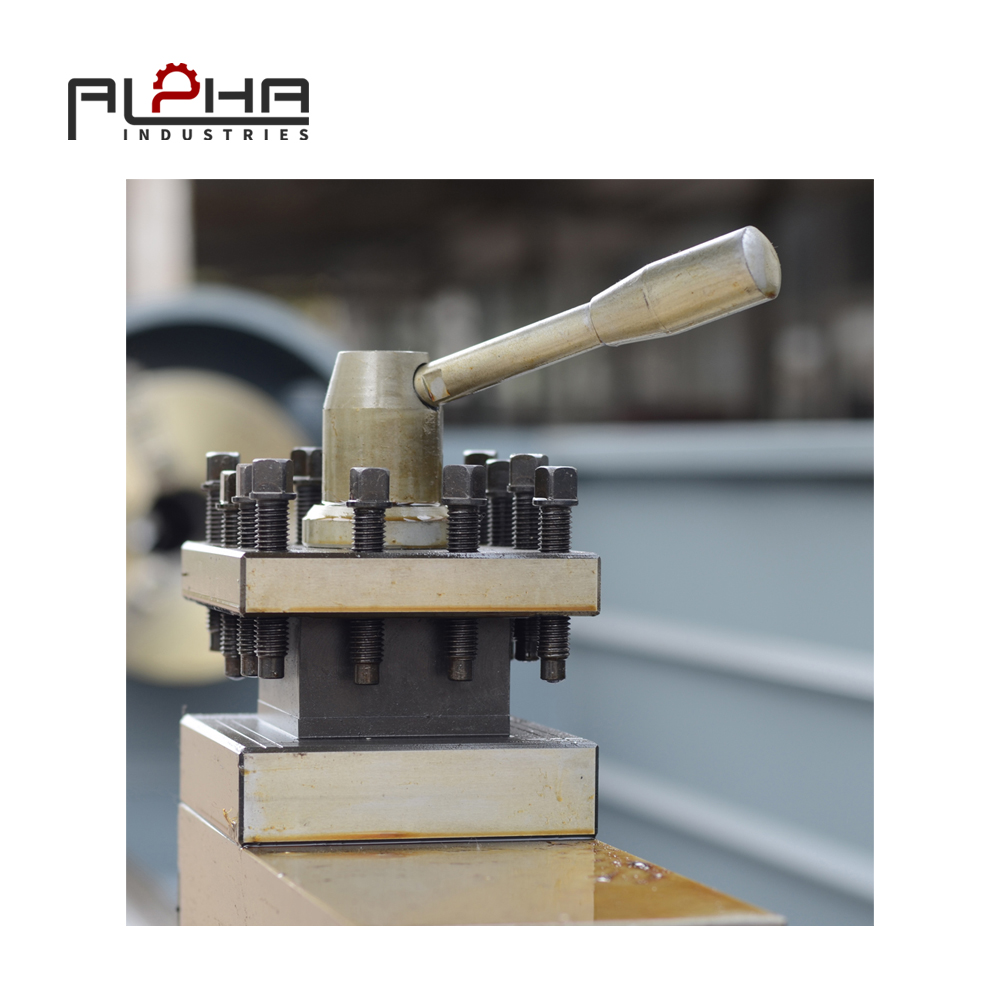

The overall performance of a lathe directly depends on the quality of its individual components and the lathe tools used. Basic lathe parts, such as head warehouses, tailgate, carriage and beds, must be designed to handle the strong workload for fixation and durability. Alpha's lathes, for example, demonstrate commitment to quality with its sophisticated precision dialing system, ergonomic controls, and powerful brass and steel materials. The right lathe tools are equally important because they interact directly with the workpiece. From cutting inserts to boring rods, using advanced tools ensures clean cuts, excellent surface surfaces, and extended operating life of the tools and the machine itself. Investing in machines with excellent parts is an investment in reliability and long-term performance.

Find a partner: Choose the right lathe supplier

In addition to the technical specifications of the machine, the lathe supplier you choose can greatly influence your success. A great supplier not only needs to sell equipment, but also can do more. They provide comprehensive support and expertise. Companies such as Nanjing Alpha CNC Co., Ltd position themselves as true solutions providers, from the choice of a single machine to the design of a complete production line. Through a professional R&D team driving innovation and commitment to responsive customer service, the right partners can receive not only products but also a complete support system. They help browse the complexity of transportation and provide ongoing help, making it a valuable asset to your business and a true partner in growth.