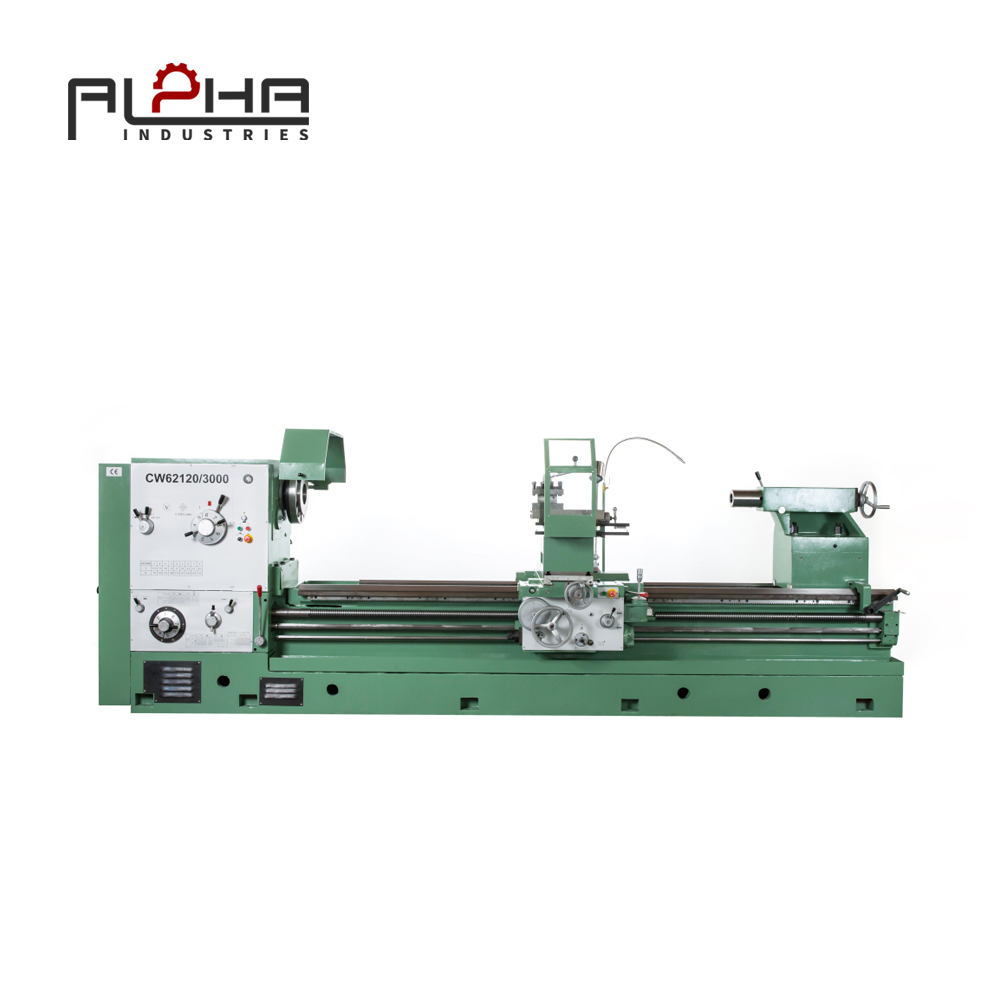

A lathe machine is one of the oldest and most versatile tools in metalworking, designed to rotate a workpiece against a cutting tool for shaping, drilling, threading, and finishing.

Unlike CNC lathes, manual lathes give operators direct control, making them suitable for workshops, repair facilities, and industries where customization and flexibility are essential.

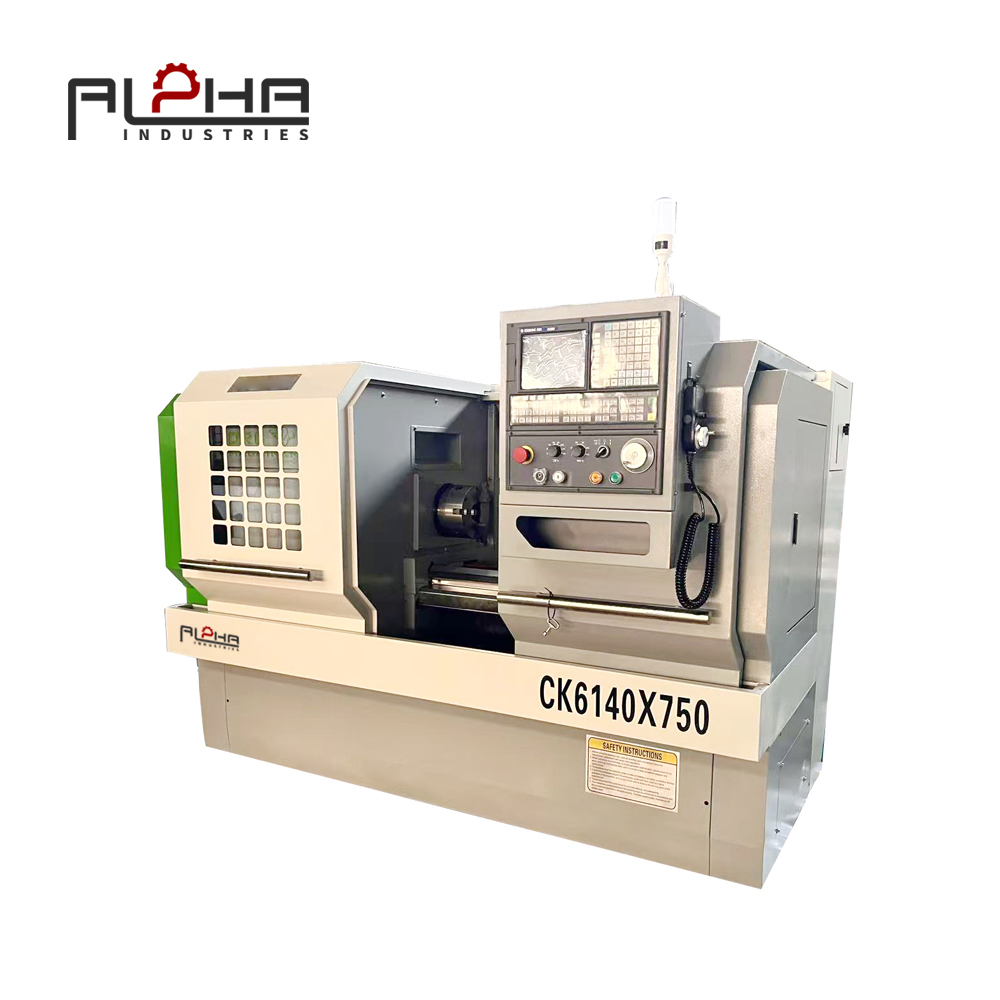

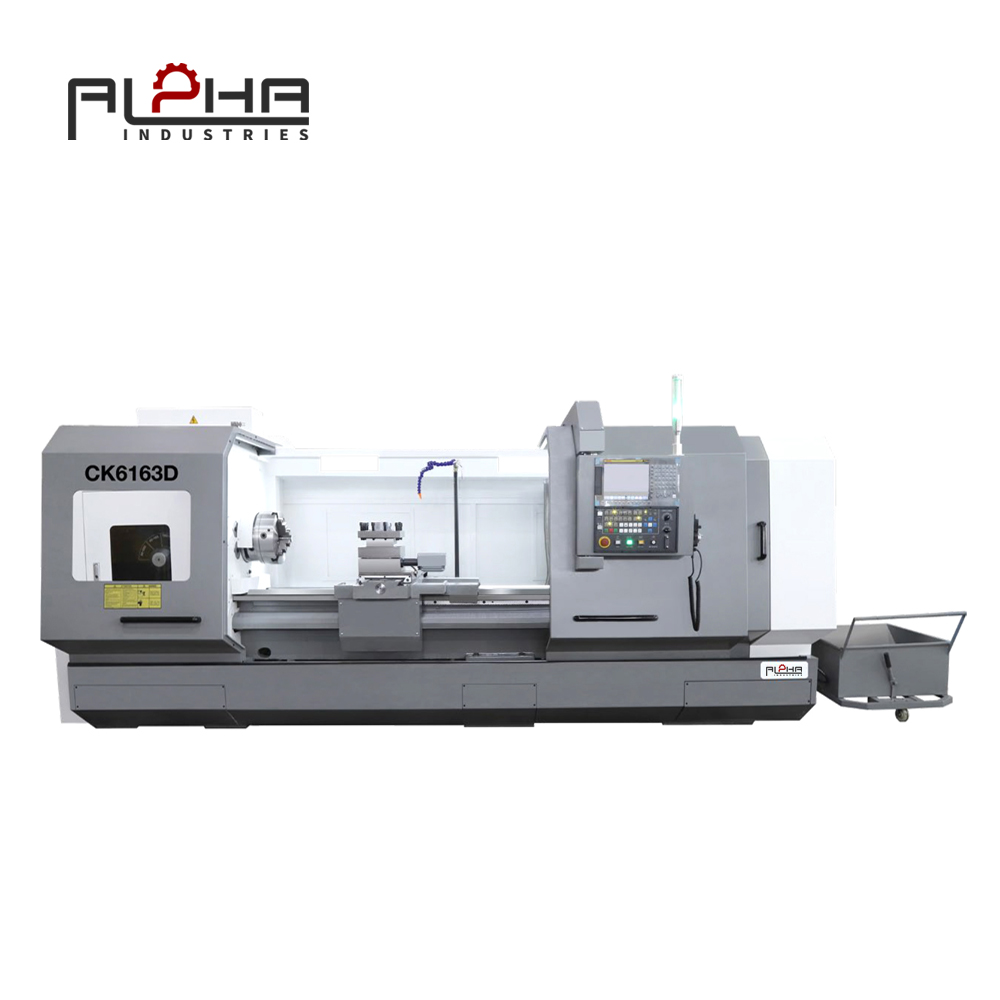

Explore the ALPHA Lathe Machine product range to find the right solution for your operations.

Key Features of ALPHA Lathe Machines

-

Heavy-Duty Construction – Built with rigid frames for stability during turning operations.

-

Versatile Applications – Capable of facing, tapering, drilling, threading, and grooving.

-

High Precision – Accurate turning with minimal vibration.

-

User Control – Manual feed and speed adjustments provide flexibility for complex tasks.

-

Durability – Designed for long service life and reliable operation.

Check our ALPHA product page for detailed specifications.

Applications of Lathe Machines

Lathe machines are widely used across industries for producing both standard and customized parts:

-

Automotive industry: Shafts, bushings, and gear components

-

Aerospace manufacturing: Precision cylindrical parts

-

Maintenance workshops: Repairing and refurbishing worn parts

-

General metal fabrication: Thread cutting, drilling, and grooving

See more real-world uses in our Lathe Machine applications article.

Common Problems with Lathe Machines and Solutions

Even the best machines can encounter issues. Here are typical problems and how to fix them:

1. Poor Surface Finish

Cause: Worn cutting tools or incorrect feed rate.

Solution:

-

Replace or sharpen cutting tools.

-

Adjust feed rate and cutting speed according to material.

2. Excessive Vibration

Cause: Workpiece not properly clamped or imbalance in the chuck.

Solution:

-

Re-clamp the workpiece securely.

-

Inspect chuck alignment and balance.

3. Inaccurate Dimensions

Cause: Tool deflection or improper calibration.

Solution:

-

Use sharp, rigid cutting tools.

-

Regularly calibrate and align the machine.

4. Overheating of Cutting Tool

Cause: Insufficient cooling or incorrect cutting speed.

Solution:

-

Apply cutting fluids.

-

Reduce spindle speed for hard materials.

Maintenance Tips for ALPHA Lathe Machines

-

Daily Cleaning: Remove chips and lubricate slides.

-

Regular Inspection: Check spindle bearings and tool posts.

-

Lubrication: Apply oil to gears and moving parts.

-

Alignment Check: Ensure tailstock and headstock alignment for precision.

For maintenance support, reach us via ALPHA contact page.

Why Choose ALPHA Lathe Machines

-

Strong and reliable performance

-

Wide range of turning operations

-

Durable construction for industrial use

-

Full technical support and spare parts availability

Explore the complete ALPHA Lathe product line for more details.

Get Your ALPHA Lathe Machine Product Brochure

For specifications, available models, and detailed technical information, download the ALPHA Lathe brochure here.