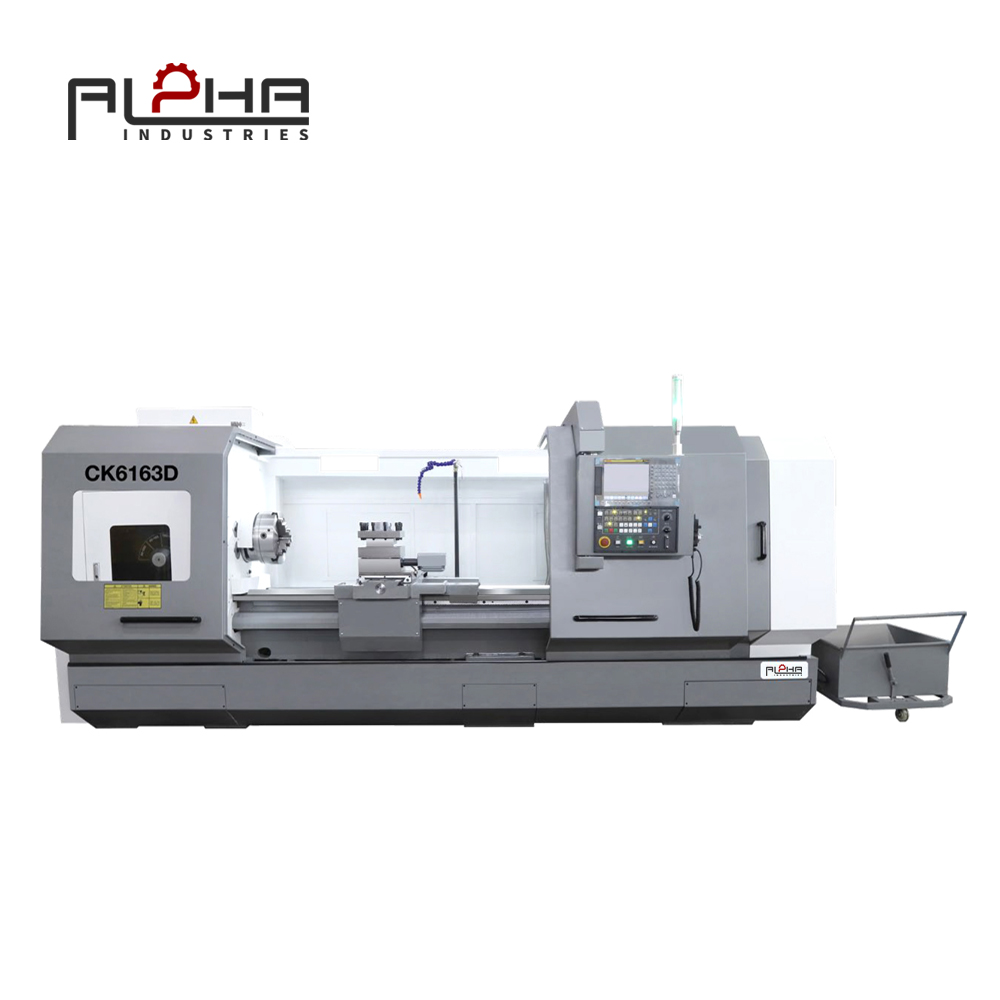

Industrial rolls, such as those used in steel mills, paper production, and rubber processing, require extreme precision in geometry and surface finish. Any deviation in roundness or surface quality can lead to production inefficiencies, product defects, and increased wear. Precision lathes designed for roll machining provide the structural rigidity, power, and control needed to process these heavy, large-diameter components while maintaining strict tolerances.

Machining Challenges of Industrial Rolls

Rolls are often several meters long and weigh multiple tons. Machining them requires overcoming:

-

Deflection Control:Preventing bending due to the roll’s own weight.

-

Surface Finish Precision:Achieving a flawless finish essential for downstream processes like coating or grinding.

-

Concentricity and Roundness:Ensuring the roll is perfectly centered to avoid imbalance at high rotational speeds.

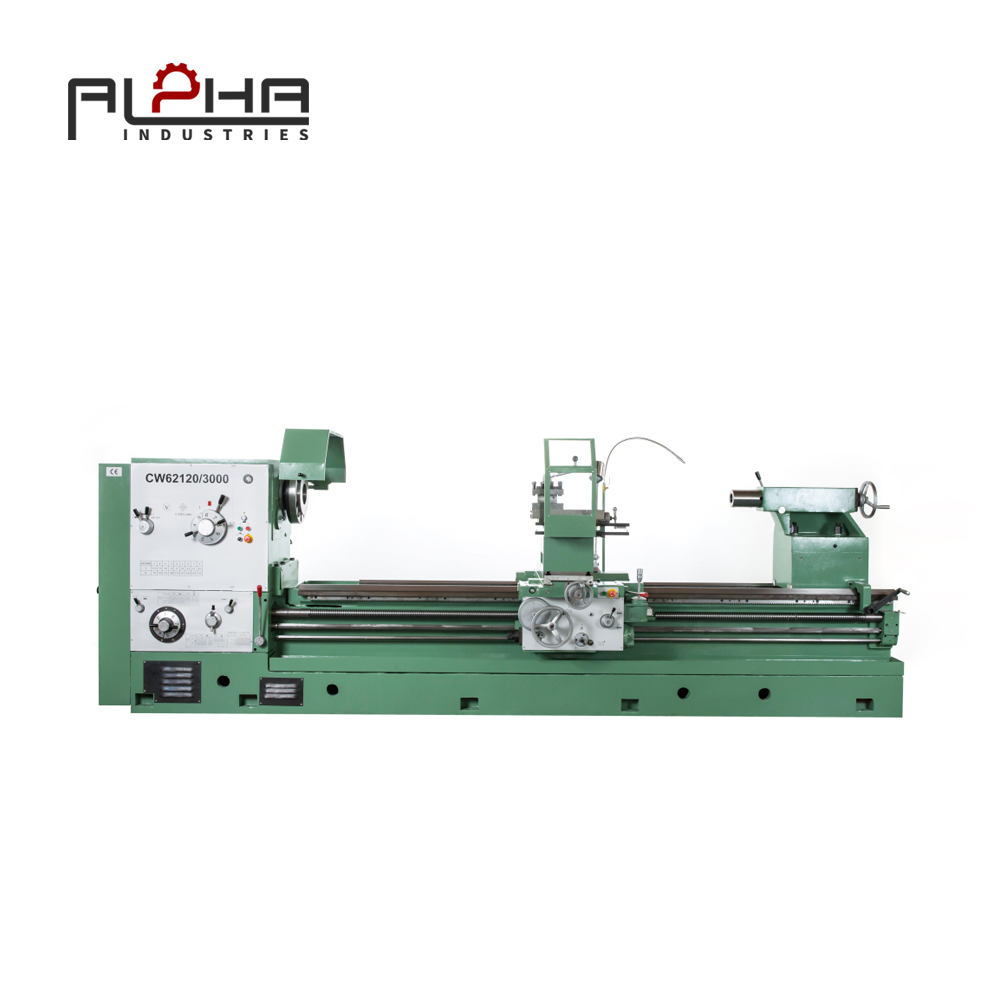

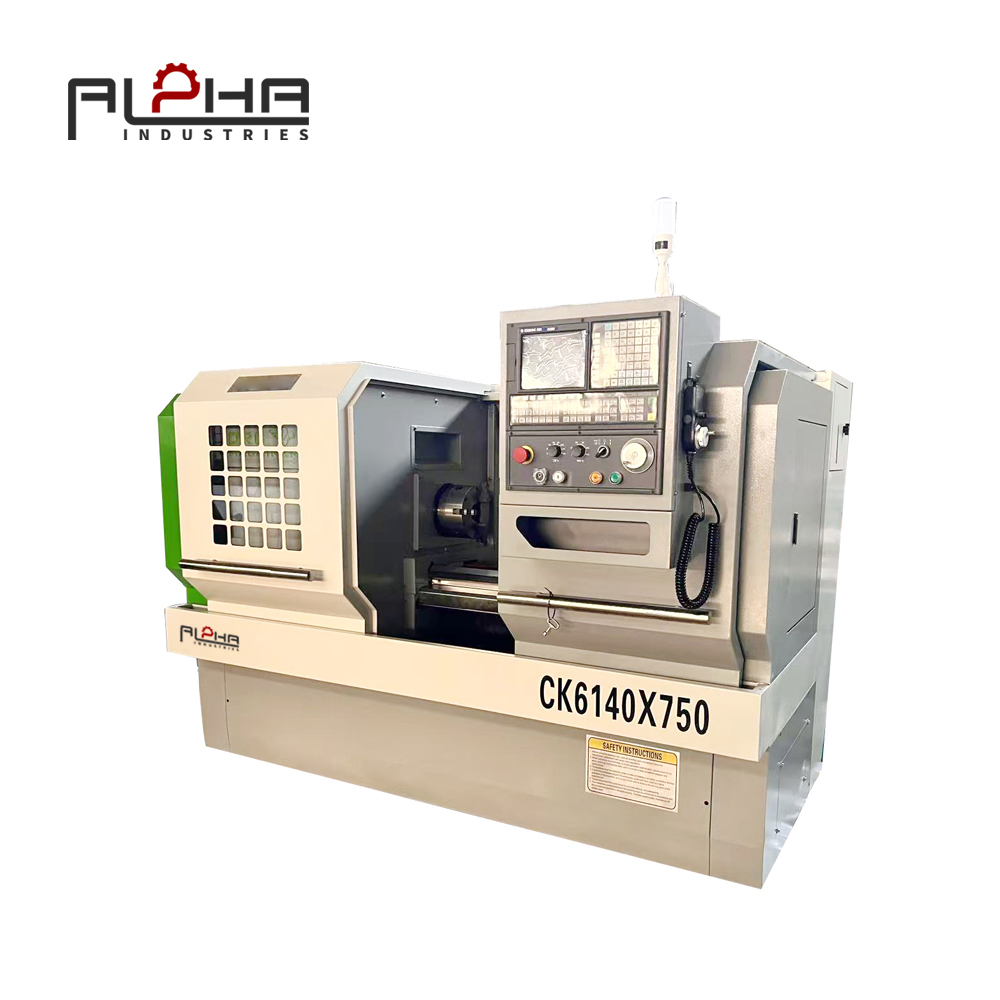

Key Features of Roll Machining Lathes

-

Ultra-Heavy-Duty Bed:Fabricated from high-strength cast iron with deep ribbing to suppress vibration and support high static loads.

-

High-Power Spindle Motors:Deliver torque sufficient to rotate and cut massive rolls with consistent speed control.

-

Customizable Steady Rests:Provide intermediate support along the roll length to prevent sagging during machining.

-

Hydraulic Tailstocks:Offer adjustable pressure to align and support the roll's ends with minimal axial displacement.

-

Precision Linear Scales:Enable micron-level positioning for consistent diameter control across the entire length of the roll.

Process Capabilities

-

OD Turning:Achieves uniform diameter across the roll’s length with strict roundness tolerances.

-

Face Machining:Ensures flat, perpendicular faces for proper assembly in rolling stands or mills.

-

Grooving and Contouring:For rolls that require specific surface profiles, such as those in paper or textile processing.

-

Pre-Grinding Preparation:Produces the ideal surface geometry before final grinding operations.

Material Compatibility

Precision roll lathes handle a variety of materials including:

-

Forged and Cast Steel:Common in heavy industry and steel rolling applications.

-

Chilled Cast Iron:Ideal for paper mill rolls with wear-resistant surfaces.

-

Alloyed Materials:For specialized applications requiring corrosion resistance or specific hardness levels.

Surface Finish and Geometry Control

Lathes for roll machining are capable of achieving:

-

Roundness Tolerance:Often within 10 microns for critical applications.

-

Surface Roughness:Typically Ra ≤ 0.8μm, ensuring compatibility with subsequent grinding or coating processes.

-

Straightness:Essential for long rolls to prevent process misalignment in end-use machinery.

Integrated Measurement and Quality Control

-

On-Machine Probing Systems:For real-time verification of diameter and profile consistency.

-

Laser Measurement Systems:Enable continuous monitoring of straightness and concentricity during turning.

-

Dynamic Balancing Preparations:Pre-machining provisions to facilitate easier balancing in later production stages.

Industrial Applications

-

Steel Mills:Work rolls, backup rolls, and intermediate rolls for hot and cold rolling lines.

-

Paper Mills:Calendar rolls and press rolls demanding smooth, precise surfaces.

-

Rubber and Plastic Industries:Processing rolls for extrusion and calendaring lines.

-

Textile Industry:Rolls for fabric finishing and treatment machinery.

Conclusion

Precision lathes for roll machining are engineered to meet the exacting requirements of industries where component mass, length, and surface quality are critical to operational efficiency. Investing in these machines ensures the production of high-performance rolls with reliable geometry, surface precision, and structural integrity.

FAQs:

1. Why is concentricity important in roll machining?

Concentricity ensures that the roll rotates evenly, preventing vibration, product inconsistencies, and premature bearing wear in high-speed industrial machinery.

2. How do steady rests enhance roll machining accuracy?

Steady rests provide critical mid-span support to long rolls, preventing deflection due to weight and cutting forces. This maintains diameter uniformity and surface integrity.

3. Can roll machining lathes handle profile and groove turning?

Yes, advanced precision lathes can perform grooving, contouring, and profiling operations, enabling the creation of specialized roll surfaces for paper, rubber, and textile industries.

4. What post-processing is common after roll turning?

After precision turning, rolls often undergo grinding to achieve ultra-fine surface finishes and dynamic balancing to ensure vibration-free performance during use.

5. What materials are commonly machined on roll lathes?

Materials include forged steel, cast iron, alloy steel, and composite materials depending on the application’s wear, hardness, and corrosion resistance requirements.