The CNC flat bed lathe is engineered for heavy-duty turning operations on large and long workpieces. Its robust flat bed structure ensures stability, minimizes vibration, and allows high-efficiency machining in industries such as energy, automotive, shipbuilding, and heavy machinery.

At Alpha, our CNC flat bed lathes combine rigid beds, high-torque spindles, and advanced CNC controls, providing precision and productivity for industrial-scale manufacturing.

Key Features of CNC Lathe Flat

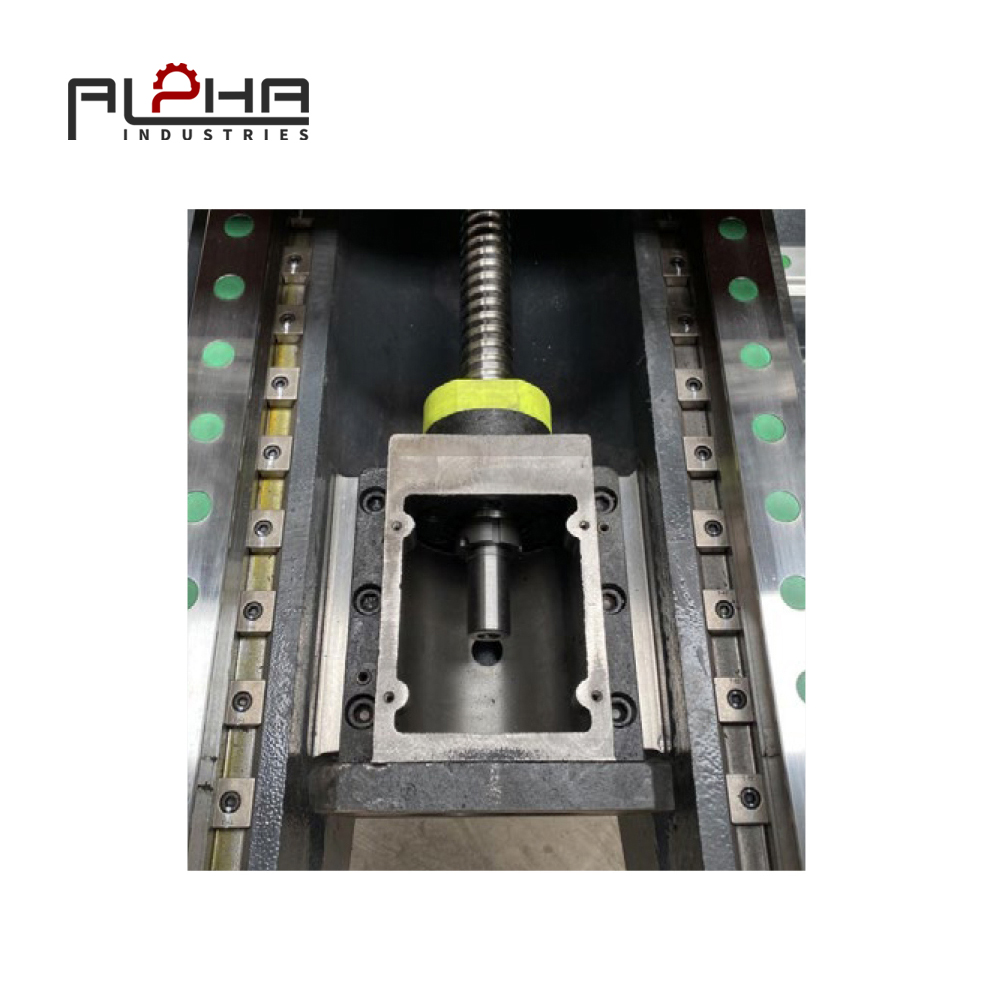

Heavy-Duty Flat Bed Design

The flat bed provides strong support for long or heavy workpieces, ensuring vibration-free machining for superior surface finish.

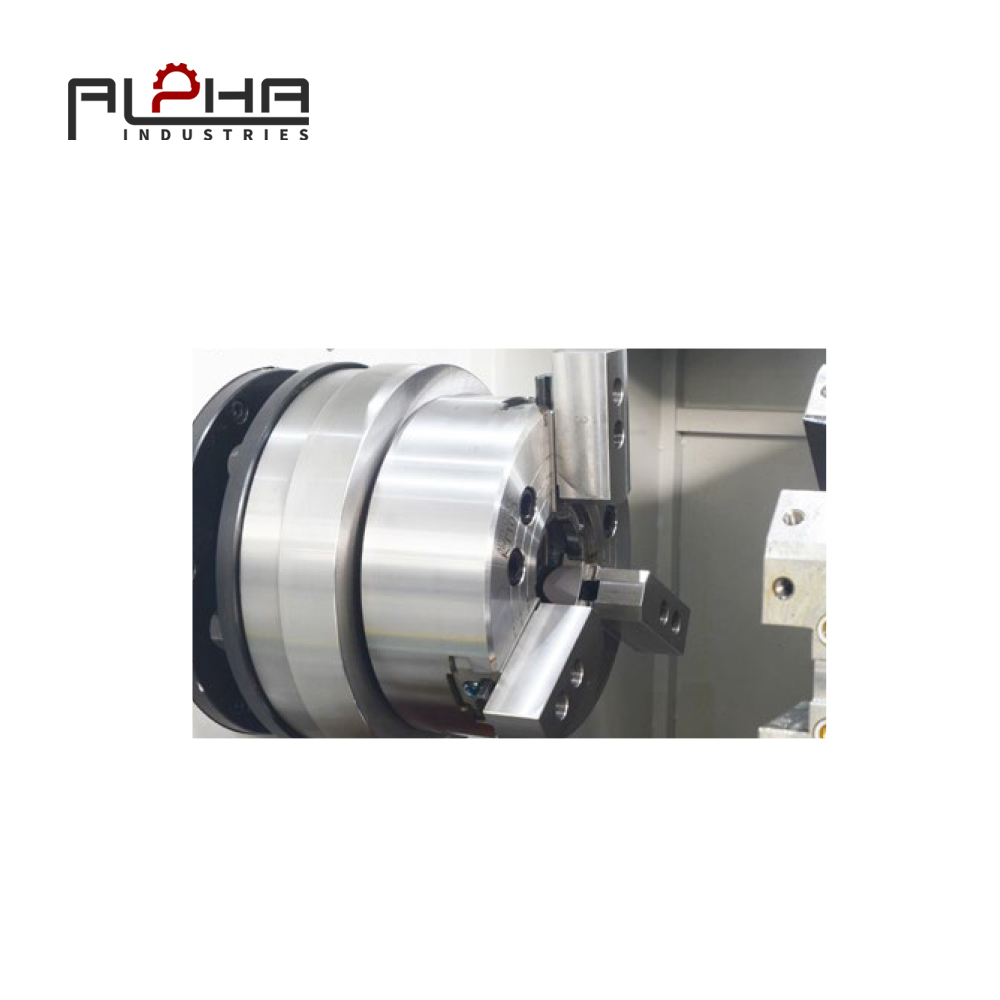

High-Torque Spindle

Equipped with robust spindles and precision bearings, Alpha’s flat bed lathes handle high cutting forces while maintaining dimensional accuracy.

Advanced CNC System

Programmable CNC controls allow repeatable operations, multi-axis machining, and automated cycles, significantly improving efficiency and reducing operator workload.

Flexible Tooling

Supports multi-turret and live tooling, enabling operations such as turning, threading, grooving, and drilling in a single setup.

Working Principle of CNC Flat Bed Lathe

The workpiece rotates on the spindle while the cutting tool moves along the linear X and Z axes, performing turning, facing, and threading. CNC control ensures precise tool paths, angle accuracy, and repeatable production.

-

Heavy-duty clamping ensures stability during long or large-diameter workpiece machining.

-

Automated turret and tool change reduce setup time.

-

Optional live tooling enables complex multi-operation machining.

Applications of CNC Flat Bed Lathe

-

Energy Industry – turbine shafts, pump rotors, and valve components.

-

Automotive – crankshafts, camshafts, and axles.

-

Shipbuilding – propeller shafts, rollers, and structural components.

-

Heavy Machinery – rollers, pins, cylinders, and structural parts.

-

General Manufacturing – precision industrial components for metalworking.

Advantages of Choosing Alpha CNC Lathe Flat

-

Stable operation for long and heavy workpieces

-

High productivity with automated CNC programming

-

Multi-operation capability in a single setup

-

Customizable spindle, tooling, and automation options

-

Global service and CE-certified quality

Frequently Asked Questions (FAQ) on CNC Lathe Flat

What types of workpieces can a CNC flat bed lathe handle?

It can machine long, heavy, or large-diameter workpieces, including shafts, rollers, and structural components.

How does a flat bed CNC lathe differ from a slant bed CNC lathe?

-

Flat bed: ideal for heavy-duty and long workpieces; provides maximum rigidity.

-

Slant bed: better for high-speed small part turning; facilitates chip removal and tool access.

Can CNC flat bed lathes perform multi-operation machining?

Yes, with multi-turret systems, live tooling, and CNC automation, the machine can perform turning, threading, drilling, and grooving in one setup.

Which industries benefit most from CNC flat bed lathes?

Industries such as energy, automotive, shipbuilding, heavy machinery, and industrial manufacturing benefit from stability, precision, and heavy-duty capability.

Does Alpha offer customized CNC flat bed lathes?

Yes, Alpha provides customized bed length, spindle speed, tooling, and automation options according to client requirements.

Partner with Alpha for Heavy-Duty Flat Bed Turning

Alpha delivers high-performance CNC flat bed lathes engineered for stability, efficiency, and heavy-duty applications. Our machines ensure precision, productivity, and long-term reliability for industrial-scale manufacturing.

Contact our experts today: Contact Us