Precision Laser Cutting with Minimal Heat-Affected Zone

In modern metal fabrication, laser cutting machines have become essential for achieving complex shapes, fine details, and high repeatability. However, the key to professional performance is not just speed—it is cutting precision and control of the heat-affected zone (HAZ).

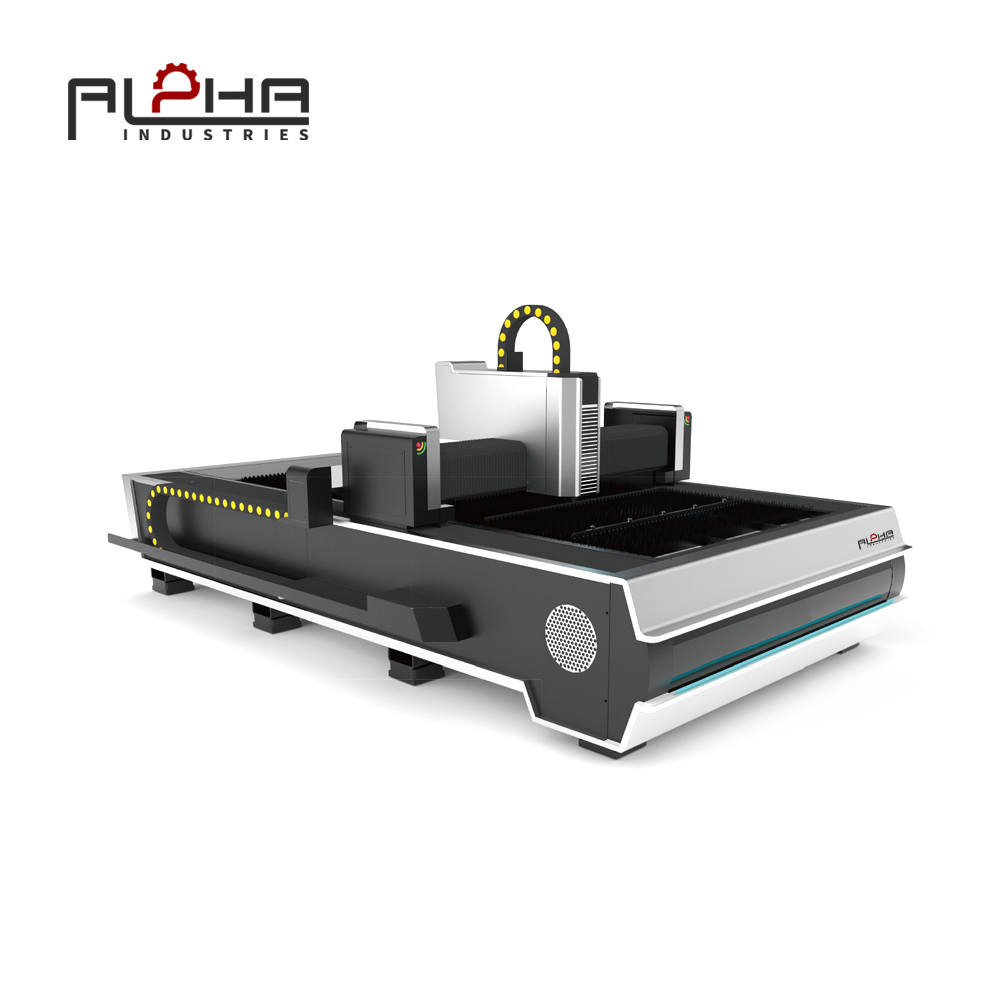

At Alpha, our laser cutting machines are engineered to deliver micron-level accuracy while minimizing thermal distortion. This article explores how precise laser control improves cutting quality, reduces post-processing, and enhances productivity.

Why Cutting Precision Matters in Laser Fabrication

Laser cutting precision determines the overall quality of metal parts. Even minor deviations can lead to:

-

Misaligned assemblies

-

Excess material waste

-

Additional finishing costs

-

Compromised mechanical performance

Alpha laser cutting machines use high-stability optical systems and advanced CNC control to maintain tight tolerances for industrial production, ensuring consistent and reliable results.

Understanding Heat-Affected Zone (HAZ) in Laser Cutting

The heat-affected zone is the area around the laser cut that experiences thermal impact, which may change the microstructure of the metal and cause:

-

Material warping

-

Surface discoloration

-

Reduced structural integrity

Minimizing HAZ is crucial for high-quality metal fabrication, especially for stainless steel, aluminum, and thin-gauge metals.

Technical Innovations in Alpha Laser Cutting Machines

1. High-Stability Laser Source

Our machines use fiber or CO₂ laser sources with:

-

Stable output power

-

Minimal beam divergence

-

Consistent focus across varying thicknesses

This ensures cuts are precise without excessive heat penetration.

2. Advanced Motion Control

Alpha integrates high-speed servo motors and linear guideways to:

-

Maintain smooth cutting trajectories

-

Reduce positioning errors

-

Allow complex 2D and 3D cutting with micron-level precision

3. Intelligent Focus and Speed Adjustment

Dynamic control of laser focus and cutting speed reduces HAZ by:

-

Matching energy density to material thickness

-

Preventing overburning

-

Maintaining clean edges with no slag

4. Optimized Assist Gas System

Correct gas type, pressure, and nozzle positioning help:

-

Remove molten material efficiently

-

Reduce oxidation

-

Minimize heat transfer to surrounding areas

Benefits of Minimal Heat-Affected Zone

-

Cleaner Edges and Reduced Finishing

High-precision cuts with minimal HAZ require less deburring and polishing. -

Higher Mechanical Integrity

Parts maintain strength and microstructure without thermal distortion. -

Greater Material Utilization

Reduced warping and distortion lowers scrap rate, saving material cost. -

Faster Production and Automation

Consistent quality enables higher-speed production for industrial batches.

Alpha Laser Cutting Machine Advantages

-

Micron-level cutting precision across various metals

-

Minimal HAZ for stainless steel, aluminum, carbon steel, and alloys

-

Optimized beam quality with advanced fiber laser or CO₂ systems

-

Intelligent CNC control with automated parameter adjustment

-

Durable structure for long-term industrial performance

With these innovations, Alpha laser cutting machines help manufacturers improve productivity, reduce post-processing, and achieve superior finished parts.

FAQ

Q1: What is the heat-affected zone in laser cutting?

A: The area around a cut affected by heat, which can alter metal microstructure and cause distortion.

Q2: How does laser cutting precision impact production?

A: Higher precision reduces scrap, improves assembly accuracy, and minimizes finishing work.

Q3: Which materials benefit most from minimal HAZ?

A: Stainless steel, aluminum, thin-gauge metals, and high-strength alloys.

Q4: Can laser cutting speed affect HAZ?

A: Yes, higher speed with correct focus reduces heat input and thermal distortion.

Q5: Why choose Alpha laser cutting machines?

A: They combine high-precision lasers, CNC control, and optimized thermal management for consistent, industrial-grade results.

Conclusion

Cutting precision and heat-affected zone control are critical for high-quality laser cutting. Alpha laser cutting machines provide stable performance, micron-level accuracy, and minimal thermal distortion, making them ideal for industrial metal fabrication.