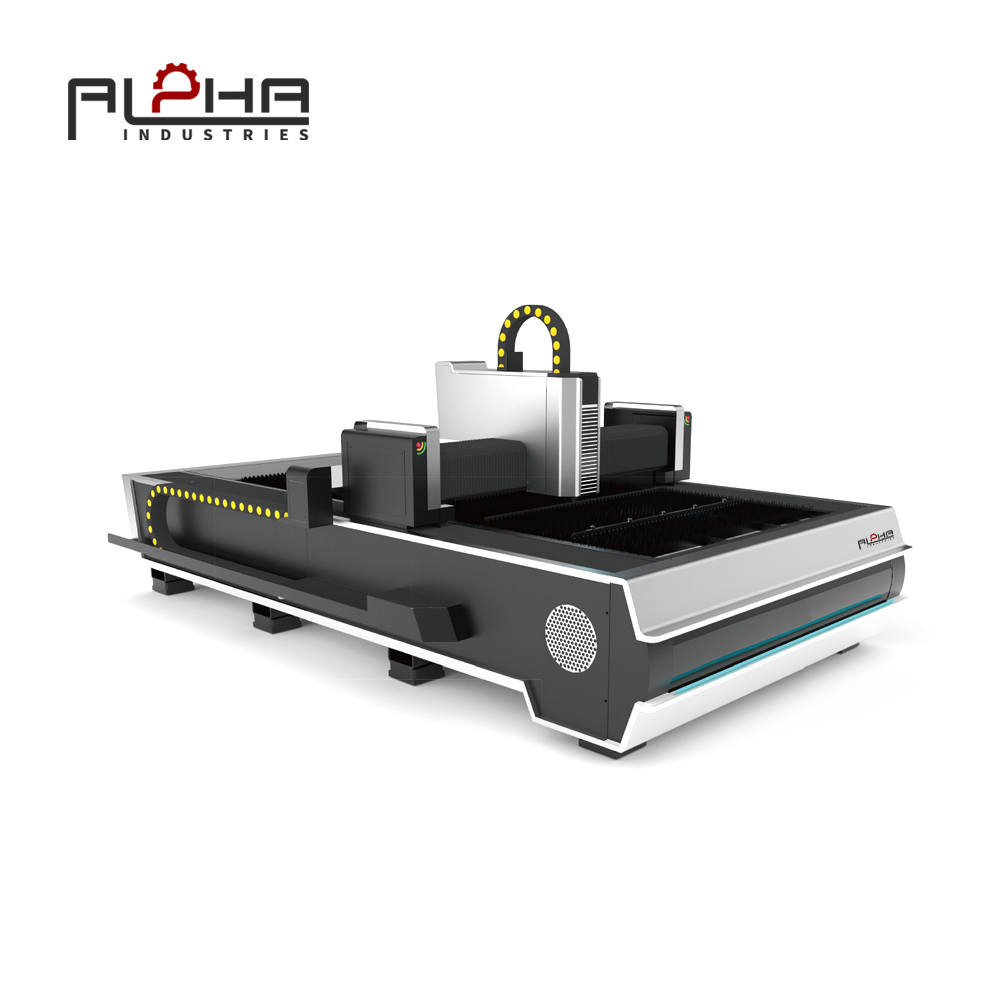

What is a Single-Platform Laser Cutting Machine?

A Single-Platform Laser Cutting Machine is a high-precision, computer-controlled equipment designed for cutting, engraving, and contouring sheet metals using a focused laser beam. Unlike dual-exchange systems, the single-platform structure features a fixed working table, which improves stability, accuracy, and consistency — especially in environments demanding micron-level precision.

At Alpha, our Single-Platform Laser Cutting Machines are engineered with a focus on rigid structure design, advanced optical systems, and motion synchronization to meet the evolving needs of industries like aerospace, automotive, precision electronics, and fabrication workshops.

Core Focus: Cutting Bed Stability — The Foundation of Optical Precision

In laser cutting, bed stability defines the cutting result. Every micron of vibration or thermal drift affects the path of the laser beam, impacting edge smoothness and dimensional accuracy. Alpha engineers the cutting platform as a structural precision system — not just a support surface.

1. One-Piece Welded Frame for Absolute Rigidity

Alpha’s single-platform machines utilize a one-piece welded frame, stress-relieved through annealing and vibration aging to eliminate residual stress.

This ensures:

-

Uniform rigidity across the entire platform.

-

No deflection under heavy sheets or rapid head movement.

-

Long-term alignment of the optical path and gantry system.

Technical Benefit:

Even during high-speed cutting at 140 m/min, vibration amplitude remains below 0.005 mm, guaranteeing ultra-stable beam accuracy.

2. Finite Element Optimized Bed Structure

Using finite element analysis (FEA), Alpha engineers refine every section of the platform. Reinforced ribs and lattice geometry ensure equal load distribution.

Key Performance Outcomes:

-

Natural frequency above 130 Hz, minimizing resonance.

-

Stable thermal behavior under continuous operation.

-

Improved laser kerf uniformity across full sheet size.

This makes Alpha’s single-platform design ideal for fine cutting, where accuracy and repeatability outweigh speed.

Optical Precision Control — The Intelligence Behind the Beam

The optical system is the “brain” of a laser cutting machine. Alpha’s precision laser cutting technology centers on optical alignment, beam consistency, and dynamic focus tracking.

1. Collimation and Focus Consistency

Alpha integrates automated optical calibration systems that maintain perfect beam alignment between collimator, focus lens, and nozzle.

Technical Highlights:

-

Auto-focus range: ±20 mm

-

Focus accuracy: ±0.01 mm

-

Automatic lens contamination detection

-

Active focal length compensation during Z-axis motion

This ensures smooth transitions when cutting materials with varying thicknesses — from 0.5 mm stainless steel to 20 mm carbon steel.

2. Intelligent Motion Synchronization

The precision of laser cutting relies not only on optics but also on synchronized motion between the X-Y gantry and cutting head. Alpha’s machine integrates:

-

Linear servo drives with nanometer resolution encoders.

-

Dual-side drive gantry synchronization using torque-balance control.

-

Real-time path correction algorithms minimizing corner burn or overshoot.

Result: contour deviation under ±0.02 mm, even during high-speed complex profiles.

3. Adaptive Gas Control System

Cutting quality is directly linked to assist gas flow (O₂, N₂, or air). Alpha’s single-platform systems employ adaptive pressure regulation that automatically adjusts gas flow to match cutting thickness and speed.

This enhances:

-

Edge smoothness for stainless steel and aluminum.

-

Cutting efficiency with reduced gas consumption.

-

Reduced oxidation and burr formation.

Thermal Stability — Protecting Accuracy in Long Cycles

Thermal expansion is a key challenge in single-platform systems since the working bed remains stationary throughout operation.

Alpha integrates multi-zone temperature sensors and closed-loop thermal compensation, ensuring:

-

Constant table flatness within ±0.01 mm.

-

Controlled laser head height, preventing focus drift.

-

Longer machine uptime without manual recalibration.

This precision thermal management ensures that even after 8-hour continuous cutting, dimensional accuracy remains consistent.

User-Centric CNC Control System

Alpha’s control interface is designed for industrial operators and smart factory integration alike. The CNC laser controller provides:

-

3D cutting path simulation and error detection.

-

Real-time feedback on laser head position and power output.

-

Auto-edge detection and nesting optimization.

-

Remote monitoring and diagnostic reporting for Industry 4.0 environments.

Supported systems include FSCUT, Beckhoff, or Precitec, with open communication protocols for MES/ERP connectivity.

Energy Efficiency and Sustainability

Alpha integrates energy-regenerative drives and auto-sleep fiber laser sources, which reduce standby power by 25% and overall energy usage by 30%.

The air-assist cutting option further minimizes dependence on high-cost nitrogen, contributing to low-carbon and sustainable manufacturing goals.

Applications of Alpha Single-Platform Laser Cutting Machine

| Industry | Typical Application |

|---|---|

| Aerospace | High-precision alloy panels, structural frames |

| Automotive | Stainless steel body parts, exhaust systems |

| Fabrication | Custom enclosures, sheet frames, supports |

| Electronics | Thin copper and aluminum parts |

| Appliance Manufacturing | Decorative panels, metal housings |

Every sector benefits from stable bed design, optical precision, and smart control integration — making Alpha machines synonymous with reliability.

FAQ:

Q1: What are the advantages of a single-platform laser cutting machine?

It provides superior stability, accuracy, and cost efficiency by minimizing structural vibration and maintenance complexity.

Q2: How does Alpha ensure precision in single-platform machines?

Through rigid frame design, thermal control, and auto-focus optical alignment, ensuring consistent cutting accuracy across long runs.

Q3: What materials can Alpha’s laser cutting machines process?

They can cut carbon steel, stainless steel, aluminum, copper, and alloy materials up to 25 mm thickness, depending on laser power.

Q4: Why choose a single-platform over an exchange table design?

Single-platform systems offer higher rigidity and simpler structure, making them ideal for precision applications where accuracy outweighs throughput.

Call to Action (CTA)

Experience precision redefined with Alpha’s Single-Platform Laser Cutting Machine — engineered for optical stability, structural rigidity, and lasting accuracy.

Explore Alpha Laser Cutting Machines

Learn more about Metal Processing Solutions