Beam Quality and Focus Control in Laser Cutting for Ultra-Precision Manufacturing

In modern laser cutting, the most critical factor determining cutting accuracy, speed, and edge finish is laser beam quality combined with precise focus control. No matter how rigid the machine structure is, poor beam mode or unstable focal position will directly lead to burrs, wide kerf, slag adhesion, and inconsistent dimensional accuracy.

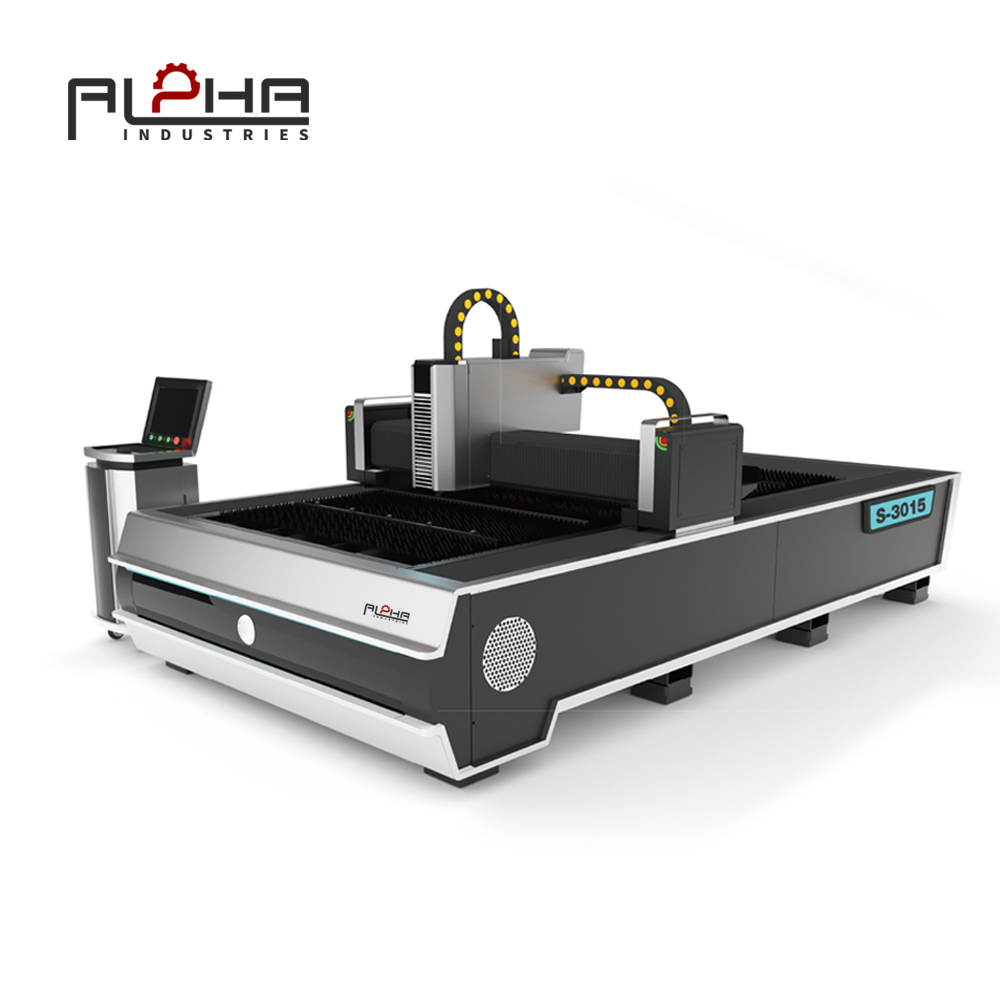

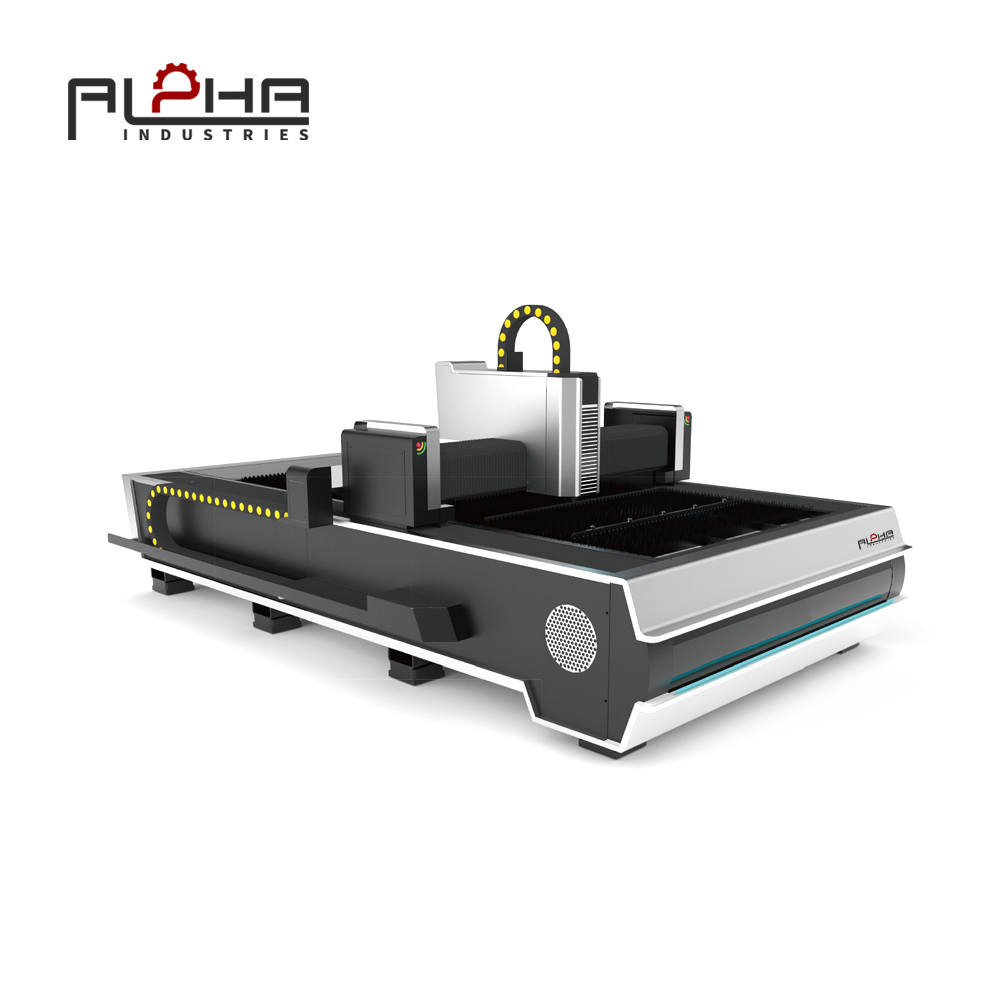

At Alpha, all industrial laser cutting machines are engineered with high-stability beam transmission systems and intelligent autofocus technology, ensuring micron-level cutting accuracy across thin sheet and thick plate applications.

This article provides a deep technical analysis of beam quality and focus control in laser cutting, explaining their direct influence on productivity, energy efficiency, and long-term machine stability.

What Is Beam Quality in Laser Cutting Machines?

Laser beam quality refers to the concentration ability, divergence angle, and energy distribution of the laser beam. It is usually described by the M² value:

-

M² ≈ 1.0 → Near-ideal Gaussian beam, best cutting precision

-

M² > 1.5 → Increased divergence, reduced cutting efficiency

A high-quality beam allows:

-

Smaller focused spot size

-

Higher energy density at the cutting point

-

Narrower kerf width

-

Smoother cut edges

In practical laser cutting operations, beam quality directly determines whether fine contours, micro-holes, and sharp corners can be processed without deformation or burning.

Why Focus Control Is the Core of Laser Cutting Accuracy

Focal Position vs Cutting Performance

The laser focus must stay exactly on or inside the material surface. If the focal point shifts:

-

Focus too high → Incomplete penetration, excessive slag

-

Focus too low → Over-burning, wide kerf, oxidation

With intelligent focus control, Alpha laser cutting systems keep the focal deviation within ±0.05 mm, ensuring consistent edge quality across the entire sheet.

Importance in Thick Plate Laser Cutting

During thick steel or stainless plate cutting, material surface height, thermal deformation, and sheet flatness change dynamically. Only real-time autofocus systems can maintain stable penetration and vertical cutting edges.

Structural Design of Alpha Beam Transmission System

High-Stability Optical Path

Alpha laser cutting systems adopt:

-

Fully enclosed dust-proof beam transmission paths

-

Anti-reflection coated optical lenses

-

Low-loss collimation modules

This minimizes:

-

Energy dispersion

-

Thermal distortion of optical components

-

Laser power loss during long operation cycles

Thermal Isolation of Optical Components

Independent cooling zones are applied to the lens group to prevent thermal focus drift during high-power continuous cutting.

Intelligent Autofocus Technology in Alpha Laser Cutting Machines

Alpha integrates servo-driven automatic focusing cutting heads, which offer:

-

High-speed focus response

-

Real-time height tracking

-

Adaptive focal length adjustment according to material type

During cutting:

-

Sensor detects material surface height

-

Controller calculates optimal focus depth

-

Servo motor adjusts cutting head position instantly

-

Laser spot remains stable at the optimal focal plane

This technology is essential for:

-

Mixed-thickness sheet processing

-

High-speed contour cutting

-

Automated production lines

The Relationship Between Beam Quality and Cutting Speed

High beam quality significantly improves:

-

Cutting speed

-

Pierce time

-

Energy utilization efficiency

For example, when cutting 3 mm carbon steel:

-

Standard beam system: ~3.5 m/min

-

High-quality beam system: 5.5–6.0 m/min

This represents over 60% productivity improvement, directly reducing per-unit manufacturing cost.

Beam Quality Influence on Edge Finish and Burr Formation

Poor beam quality leads to:

-

Irregular striation lines

-

Thick bottom burrs

-

Black oxidation zones on stainless steel

With optimized beam and focus control, Alpha laser cutting machines achieve:

-

Minimal burr formation

-

Uniform vertical kerf walls

-

Reduced secondary deburring requirement

This is particularly important for industries requiring direct assembly without post-processing.

Beam Quality Stability in Long-Time Industrial Operation

In continuous 24-hour production, beam quality degradation is usually caused by:

-

Optical lens contamination

-

Thermal lensing

-

Mechanical vibration of optical systems

Alpha prevents these issues through:

-

Automatic lens contamination monitoring

-

Constant-temperature optical cooling

-

Anti-vibration beam path design

This guarantees long-term beam stability even under full-load production.

Comparison – High-Quality Beam vs Conventional Beam in Laser Cutting

| Item | High-Quality Beam System | Conventional Beam System |

|---|---|---|

| Focus spot size | Smaller | Larger |

| Energy density | High | Medium |

| Cutting speed | Fast | Normal |

| Edge finish | Smooth | Rough |

| Burr generation | Minimal | Obvious |

| Power efficiency | High | Lower |

For high-precision metal laser cutting, beam quality is now a key purchasing decision factor.

Application Industries Highly Dependent on Beam Quality

High beam quality and stable focus control are critical for:

-

Automotive thin-sheet precision parts

-

Electrical cabinet and enclosure industries

-

Medical metal component manufacturing

-

Aerospace aluminum structure parts

-

High-end stainless steel decorative panels

In these industries, edge accuracy and appearance consistency directly affect product value and brand perception.

How Alpha Ensures Beam Quality in Every Laser Cutting Machine

Each Alpha laser cutting system undergoes:

-

Beam mode analysis and M² testing

-

Cutting head focal calibration

-

Optical transmission loss inspection

-

High-speed continuous cutting simulation

-

72-hour full-power stability testing

Only machines that meet industrial-grade beam quality standards are approved for shipment.

FAQ

Q1: What determines the accuracy of a laser cutting machine?

The laser beam quality and real-time focus control system are the most critical factors affecting cutting accuracy.

Q2: Why is autofocus important in laser cutting?

Autofocus ensures the laser stays at the optimal focal position despite material height variations, improving edge quality and penetration stability.

Q3: Does better beam quality improve cutting speed?

Yes. High-quality beam concentration significantly increases cutting speed and reduces pierce time.

Q4: How often should laser focusing systems be calibrated?

Under industrial use, focus calibration is recommended every 3–6 months to maintain stable cutting accuracy.

Explore our Press Brake for Precision Sheet Metal Bending

View our Industrial Lathe Machines for Shaft Turning

Discover our Vertical Machining Center for Complex Milling

Browse the full range of Metal Processing Machinery by Alpha