A CNC flat bed lathe is a precision machining tool designed for turning cylindrical or complex components with high accuracy and stability. It is widely used in automotive, aerospace, energy, and heavy machinery manufacturing.

At Alpha, our CNC flat bed lathes combine rigid bed structures, high-performance spindles, and advanced CNC control systems to deliver superior surface finish, tight tolerances, and reliable production efficiency.

Key Features of CNC Lathe Flat

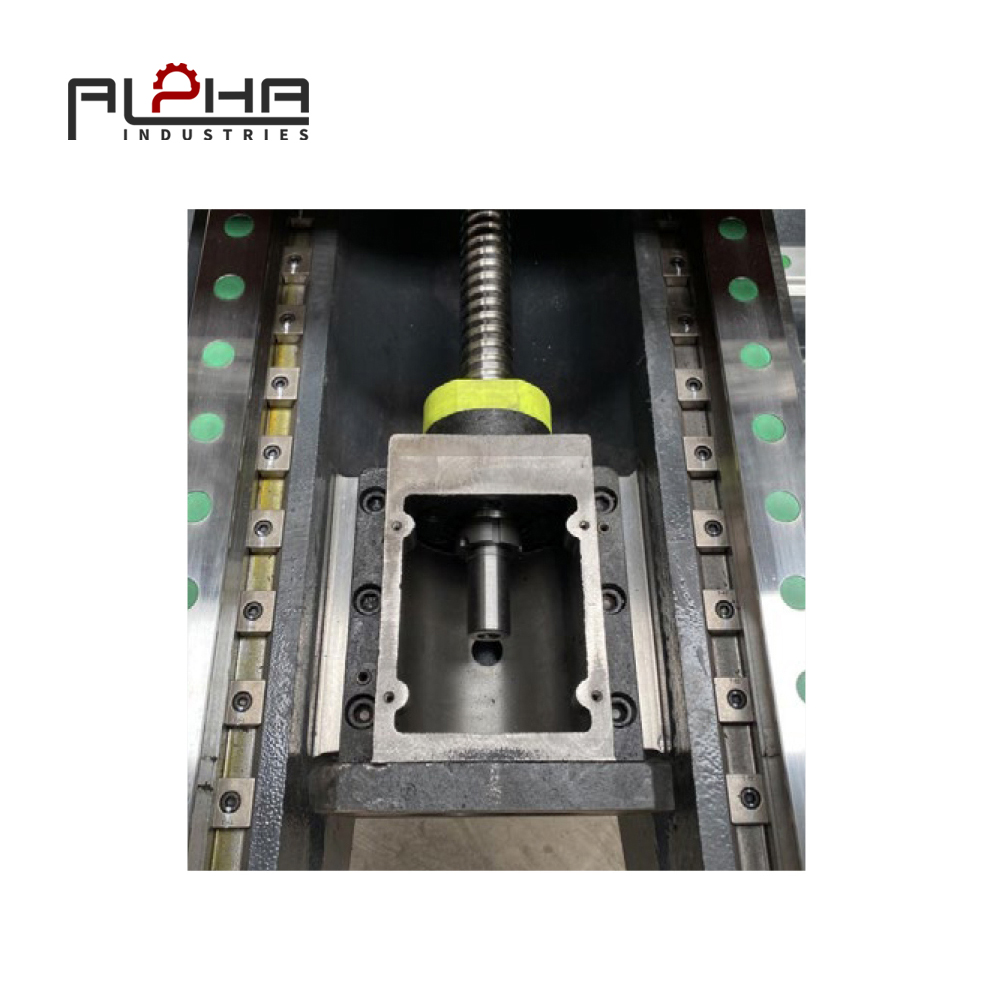

Rigid Flat Bed Design

The flat bed structure provides stability and vibration resistance, ensuring precise cutting even under heavy-duty machining.

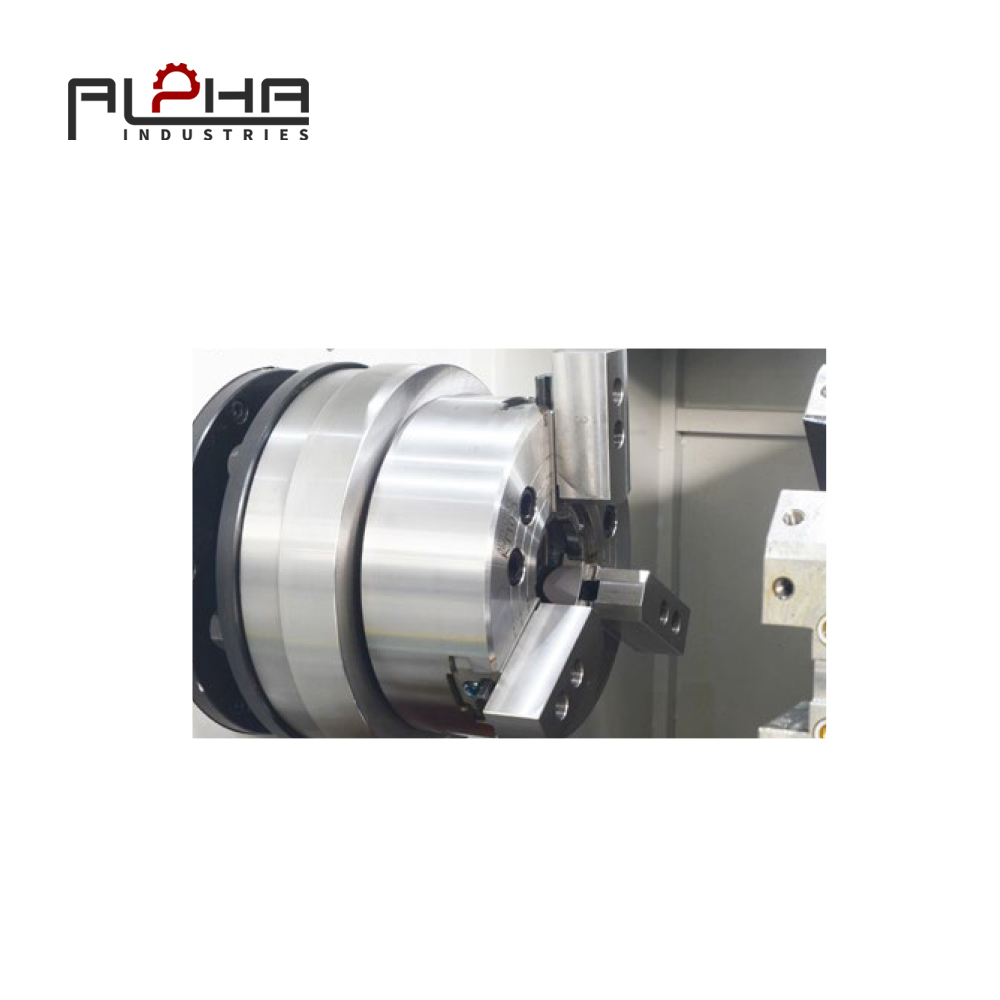

High-Precision Spindle System

Equipped with precision bearings and high-speed spindles, Alpha’s flat bed lathes achieve excellent rotational accuracy for fine turning and threading operations.

Advanced CNC Control

Integrated CNC controllers allow programmable tool paths, repeatable operations, and automated cycles, improving productivity and reducing human error.

Versatile Tooling Options

Supports multiple tool turrets and live tooling, enabling complex operations like grooving, threading, drilling, and facing in a single setup.

Working Principle of CNC Flat Bed Lathe

The workpiece is mounted on the spindle and rotates while the cutting tool moves along linear axes. Controlled by the CNC system, the tool performs precise turning, facing, and threading.

-

Linear X and Z axes provide high accuracy and smooth surface finish.

-

Automated tool change reduces setup time for batch production.

-

Optional live tooling allows multi-operation machining without repositioning.

Applications of CNC Flat Bed Lathe

-

Automotive – shafts, gears, and engine components.

-

Aerospace – structural components and precision connectors.

-

Energy – turbine shafts, pump rotors, and valve components.

-

Heavy Machinery – rollers, pins, and structural parts.

-

General Manufacturing – customized metal components requiring high precision.

Advantages of Choosing Alpha CNC Lathe Flat

-

High machining accuracy and surface finish

-

Robust flat bed structure for vibration-free operation

-

Automation for repeatable production and reduced labor

-

Customizable spindle speed and tooling configuration

-

Global after-sales service and CE-certified quality

Frequently Asked Questions (FAQ) on CNC Lathe Flat

What is a CNC flat bed lathe used for?

It is used to machine cylindrical, conical, and complex metal components with high precision and repeatability.

How do I select the right CNC flat bed lathe?

Consider workpiece size, spindle speed, bed length, tooling options, and automation level based on your production needs.

What is the difference between flat bed and slant bed CNC lathes?

-

Flat bed: offers robust stability for long or heavy workpieces, ideal for heavy-duty machining.

-

Slant bed: allows better chip removal and easier access, suited for high-speed turning of smaller parts.

Can Alpha CNC flat bed lathes handle multi-operation machining?

Yes, with multi-tool turrets, live tooling, and automated cycles, the machine can perform turning, threading, drilling, and grooving in a single setup.

Which industries benefit most from CNC flat bed lathes?

Industries including automotive, aerospace, energy, heavy machinery, and precision manufacturing benefit from the machine’s high accuracy and repeatability.

Partner with Alpha for CNC Flat Bed Turning

Alpha provides high-performance CNC flat bed lathes designed for precision, efficiency, and long-term reliability. Whether for industrial batch production or custom machining, our solutions meet global quality standards.

Contact our team today: Contact Us