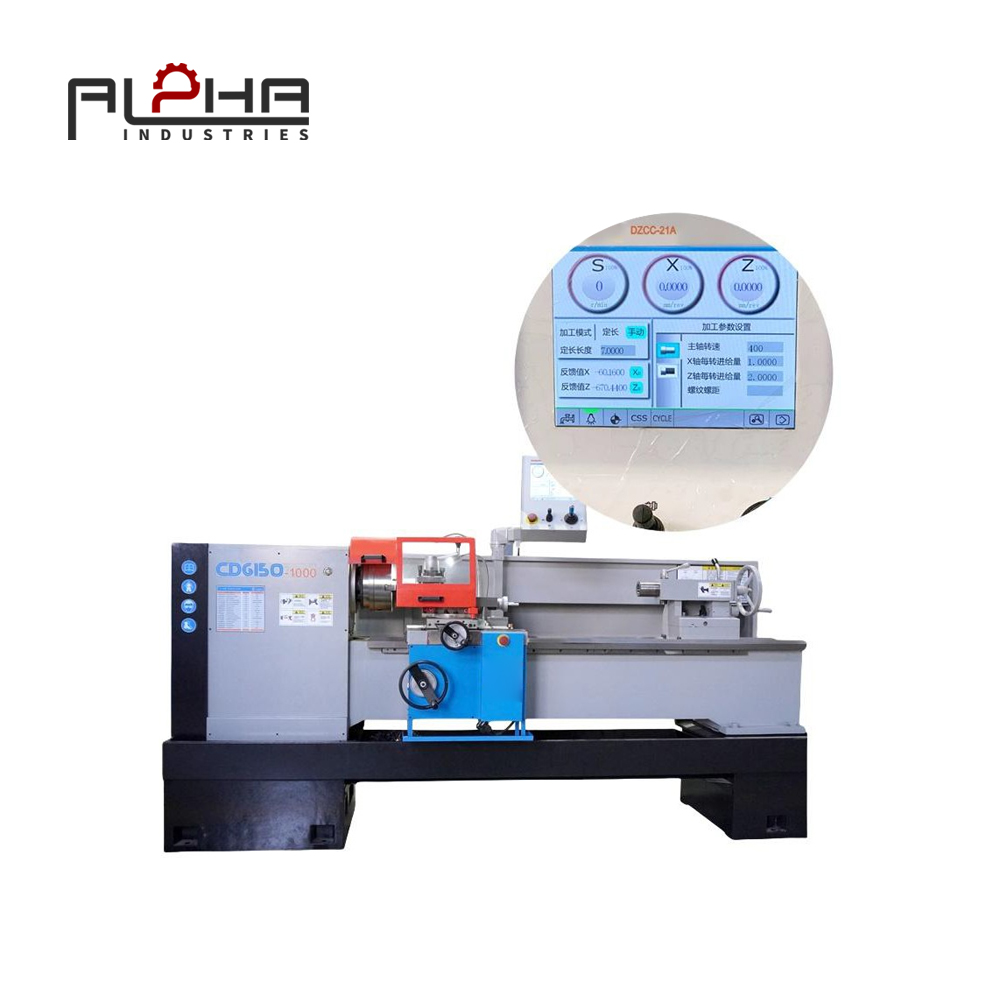

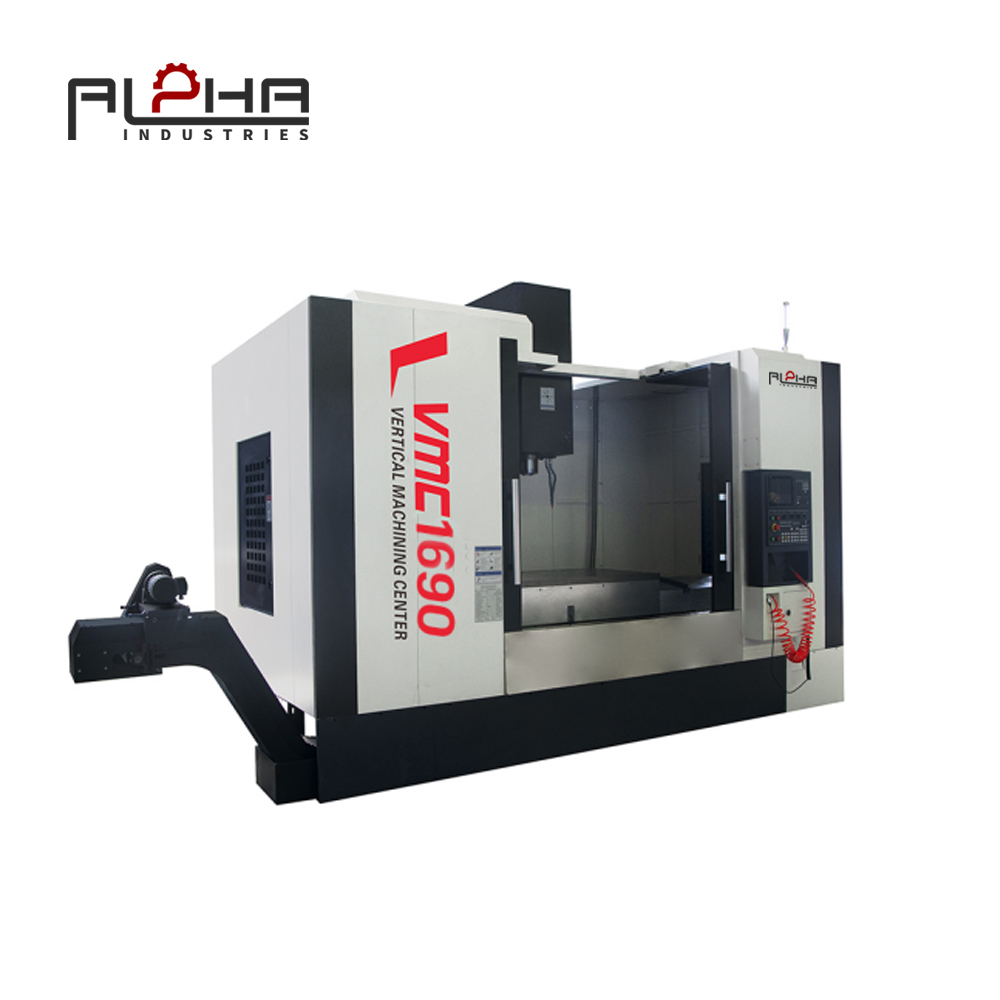

Disc-shaped components such as brake discs, flanges, and pulleys require precise machining to ensure geometric accuracy, balance, and surface integrity. CNC lathes specifically designed for disc component machining combine powerful spindles, rigid structures, and advanced tooling systems to meet the stringent demands of automotive, heavy machinery, and industrial sectors.

Technical Requirements in Disc Machining

-

Face and OD Precision:Essential for proper mating and rotational balance in assemblies.

-

Parallelism of Surfaces:Critical in brake discs to ensure uniform braking force and avoid vibrations.

-

Concentricity:Maintains consistent rotation in dynamic applications like pulleys and flanges.

-

Superior Surface Finish:Minimizes friction and wear, particularly in braking systems.

Key Features of CNC Lathes for Disc Components

-

High-Rigidity Bed and Spindle:Supports heavy disc components and suppresses vibration during cutting.

-

Powerful Chuck Systems:Provide secure clamping of disc parts, preventing slippage or misalignment.

-

Dual Turret Options:Enable simultaneous face and diameter machining, reducing cycle times.

-

Integrated Probing Systems:For in-process measurement of critical dimensions and real-time quality control.

-

High-Speed Spindles:Deliver excellent surface finishes on cast iron, steel, and aluminum discs.

Materials Commonly Machined

-

Cast Iron:Predominantly used for brake discs due to wear resistance and thermal stability.

-

Carbon Steel:Common in industrial flanges and pulleys requiring strength and toughness.

-

Aluminum Alloys:Used in lightweight automotive components for better fuel efficiency.

-

Alloy Steels:For components needing enhanced fatigue resistance and durability.

Process Capabilities

-

Face and OD Turning:Ensures flatness and diameter control for disc faces and outer edges.

-

Grooving and Slotting:Required for vented brake discs or flanges with bolt patterns.

-

Drilling and Tapping (with Live Tooling):For producing holes and threads directly on the lathe.

-

Surface Finishing:Achieves Ra ≤ 0.8μm, suitable for brake disc surfaces to minimize wear.

Industrial Applications

-

Automotive:Brake discs, flywheels, and clutch plates needing high concentricity and balanced rotation.

-

Heavy Equipment:Industrial flanges and couplings for mining, construction, and energy sectors.

-

Pulleys and Sheaves:Precision-machined for power transmission in mechanical systems.

-

Aerospace:Disc components in turbine assemblies requiring strict geometric tolerances.

Quality Control and Assurance

-

In-Process Measurement:Verifies diameter, thickness, and concentricity without removing the part from the machine.

-

Balancing Preparation:Disc components can be pre-machined with features that aid dynamic balancing.

-

Thermal Compensation:CNC controls adjust machining parameters to account for temperature-induced distortions.

Advantages of CNC Lathes for Disc Machining

-

High Production Efficiency:Reduced cycle times via simultaneous multi-tool operations.

-

Consistent Precision:Essential for large-volume automotive production where every disc must meet exact specifications.

-

Versatility:Adaptable to a range of disc diameters and thicknesses with quick tooling changeovers.

-

Reduced Post-Processing:Excellent as-machined surfaces often eliminate the need for further finishing.

Conclusion

CNC lathes tailored for disc component machining provide the precision, efficiency, and reliability required in modern manufacturing. Whether producing automotive brake discs, industrial flanges, or mechanical pulleys, these machines ensure the dimensional integrity and performance that industries demand.

FAQs:

1. Why is surface finish important in brake disc machining?

A fine surface finish on brake discs reduces friction variability, enhances braking consistency, and extends the lifespan of both the disc and brake pads.

2. Can CNC lathes perform both turning and drilling on disc components?

Yes, CNC lathes equipped with live tooling can perform drilling, tapping, and milling operations in the same setup, streamlining production.

3. How is concentricity ensured in disc machining?

Precision CNC lathes use in-process probes, rigid clamping, and high-accuracy spindles to maintain concentricity, preventing imbalance during rotation.

4. What materials are best for high-performance brake discs?

Cast iron remains the most common due to its wear resistance and heat stability, but carbon composites and advanced alloys are used in high-performance and racing applications.

5. How does CNC lathe automation improve disc component production?

Automation reduces manual handling, improves cycle consistency, and enables continuous production with features like bar feeders, robotic loading, and integrated inspection.