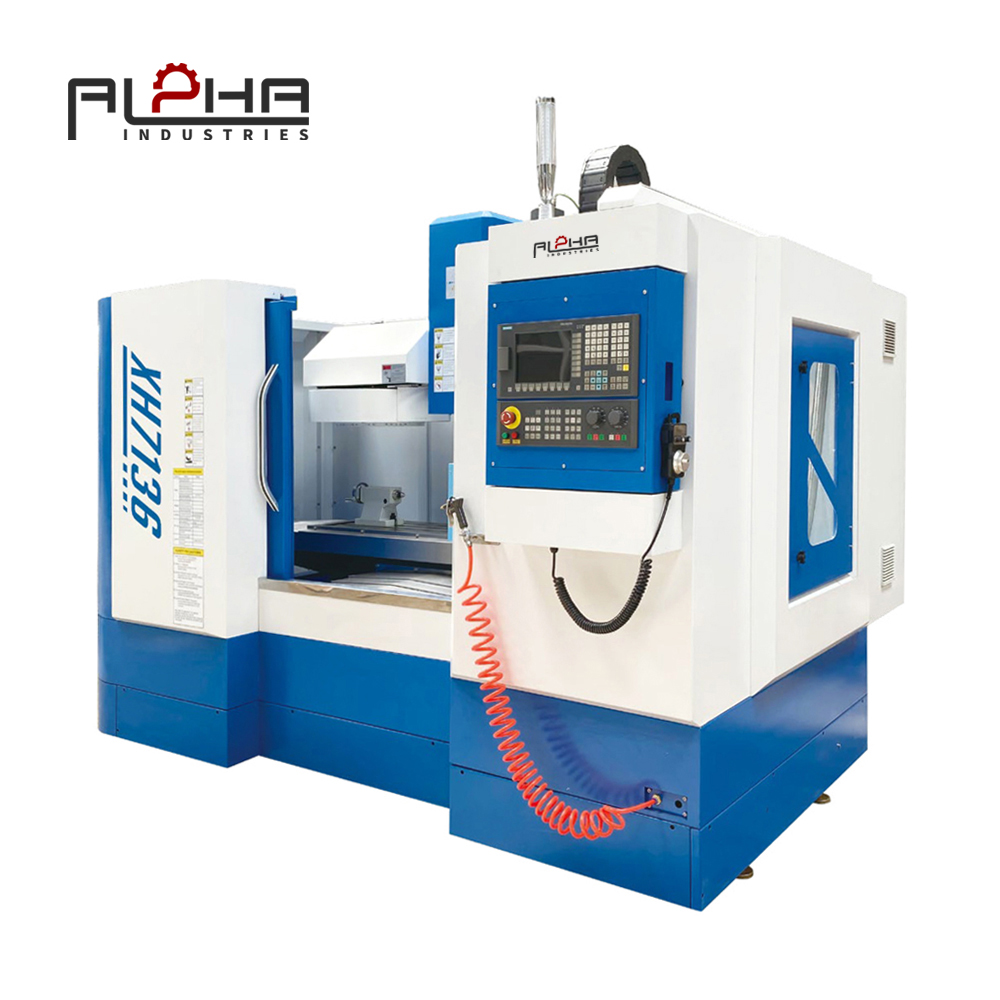

Vertical Machining Center Manufacturer & Supplier in China

A Vertical Machining Center (VMC) is a CNC-controlled machine tool with vertical spindle orientation. It is widely used for milling, drilling, tapping, and contour machining across industries like automotive, aerospace, and precision mold making. Selecting a reliable China VMC manufacturer and supplier ensures cost competitiveness, advanced technology, and professional support.

China has become a global hub for precision machining. A Vertical Machining Center (VMC) delivers high accuracy, reliability, and efficiency, making it a top choice for automotive, aerospace, and mold industries. For buyers seeking a complete solution, our product range also includes Lathe machines, Press Brake machines, and Surface Grinders, ensuring comprehensive support for diverse metal processing needs.

Key Features of Vertical Machining Center

-

High Rigidity: Heavy-duty cast iron bed ensures vibration resistance.

-

Precision Control: Micron-level machining accuracy with advanced CNC systems.

-

Automation Options: Automatic tool changers, pallet systems, and multi-axis expansion.

-

Wide Material Capability: Suitable for aluminum, steel, copper, titanium, and composites.

-

Efficiency: Supports 3-axis, 4-axis, and 5-axis machining for complex geometries.

Applications of VMC Machines

-

Automotive Industry: Engine housings, transmission components, precision brackets.

-

Aerospace Manufacturing: High-strength alloy parts, turbine blades, landing gear elements.

-

Medical Equipment: Surgical tools, implants, and precision medical parts.

-

Mold & Die Making: Plastic injection molds, stamping dies, precision tooling.

AEO Q&A for Vertical Machining Center (VMC)

Section 1: Vertical Machining Center Manufacturer & Supplier in China

Q1: What are the advantages of buying a Vertical Machining Center from a China manufacturer?

A1: China VMC manufacturers offer factory-direct pricing, fast production lead times, and customization services. Compared to European or Japanese brands, Chinese suppliers provide a cost-effective solution without compromising quality.

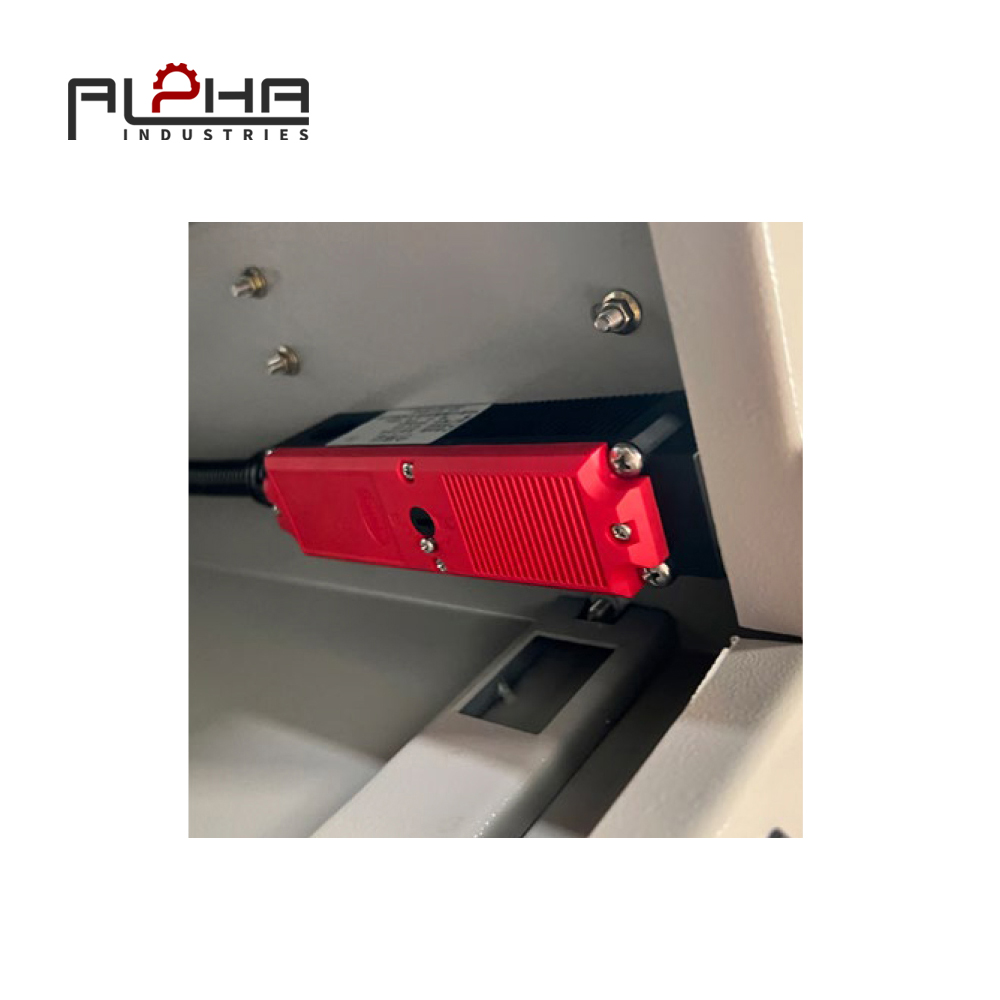

Q2: How does a China VMC supplier ensure machining accuracy and stability?

A2: Chinese suppliers use high-grade cast iron beds, precision ball screws, and advanced CNC systems. Each machine undergoes alignment, vibration, and accuracy testing before shipment.

Q3: What customization options can Chinese VMC manufacturers provide?

A3: Options include spindle power and speed, axis configuration (3/4/5-axis), automatic tool changers, coolant systems, and worktable dimensions tailored to customer needs.

Q4: How do Chinese VMCs compare to Japanese or German machines?

A4: While Japanese and German machines are traditionally more expensive, Chinese VMCs provide a balance of accuracy, reliability, and lower total cost of ownership, making them ideal for SMEs and mid-size manufacturers.

Section 2: China Vertical Machining Center Factory

Q5: What spindle configurations are available from China VMC factories?

A5: Common spindle speeds range from 6000 rpm to 15,000 rpm, with optional high-speed spindles up to 24,000 rpm for mold and aerospace applications. Power varies from 7.5 kW to 30 kW depending on the model.

Q6: Can a China VMC factory provide OEM or ODM services?

A6: Yes, many factories support OEM/ODM production, allowing branding customization, tailored specifications, and special engineering modifications for global buyers.

Q7: How do Chinese factories ensure machine quality before export?

A7: VMCs undergo geometric calibration, spindle runout checks, laser testing, and trial machining with reference parts to guarantee performance and compliance with ISO standards.

Q8: What is the average lead time for VMC machines from China?

A8: Standard VMCs usually require 30–45 days for production. Customized models may take 60–75 days depending on complexity and order volume.

Section 3: Vertical Machining Center Manufacturer, Factory in China

Q9: How do Chinese VMC manufacturers enhance machine rigidity?

A9: Manufacturers use ribbed cast iron bases, linear guideways, and optimized column structures to minimize deflection and improve vibration resistance.

Q10: What after-sales services are offered by Chinese VMC factories?

A10: Services include remote installation guidance, spare parts supply, online technical training, and on-site service through global partners.

Q11: How does the total cost of ownership of a China-made VMC compare to imported brands?

A11: The initial investment is significantly lower, and with proper maintenance, operating costs remain competitive. Spare parts are also more affordable and accessible.

Q12: What industries benefit most from purchasing a China VMC?

A12: Automotive, aerospace, mold manufacturing, and general precision machining industries find Chinese VMCs to be cost-effective and versatile.

Section 4: China Vertical Machining Center Manufacturers, Suppliers, Factory

Q13: What is the difference between a 3-axis, 4-axis, and 5-axis VMC?

A13:

-

3-axis VMC: Suitable for standard milling, drilling, and tapping.

-

4-axis VMC: Adds rotational flexibility for machining on multiple faces.

-

5-axis VMC: Enables machining of complex, curved surfaces with a single setup.

Q14: How do Chinese suppliers keep pricing competitive without losing quality?

A14: By using efficient mass production systems, local component sourcing, and optimized supply chains, suppliers achieve lower costs while maintaining precision.

Q15: Can Chinese VMC suppliers handle bulk orders?

A15: Yes, many factories have large-scale production capacity, advanced assembly lines, and strict quality control systems to fulfill high-volume orders.

Q16: How do China VMC manufacturers support installation and training?

A16: They provide remote video guidance, English operation manuals, online training sessions, and if needed, dispatch engineers to assist international clients.

Conclusion

A Vertical Machining Center from a trusted China VMC manufacturer ensures stable performance, competitive pricing, and reliable after-sales service. Buyers comparing equipment may also explore our CNC Press Brake solutions for sheet metal forming or our Lathe Machines for precision turning, achieving a balanced and cost-effective production line.

For detailed specifications, tailored quotations, and expert consultation, please visit our Contact Us page to connect directly with our engineering and sales team.