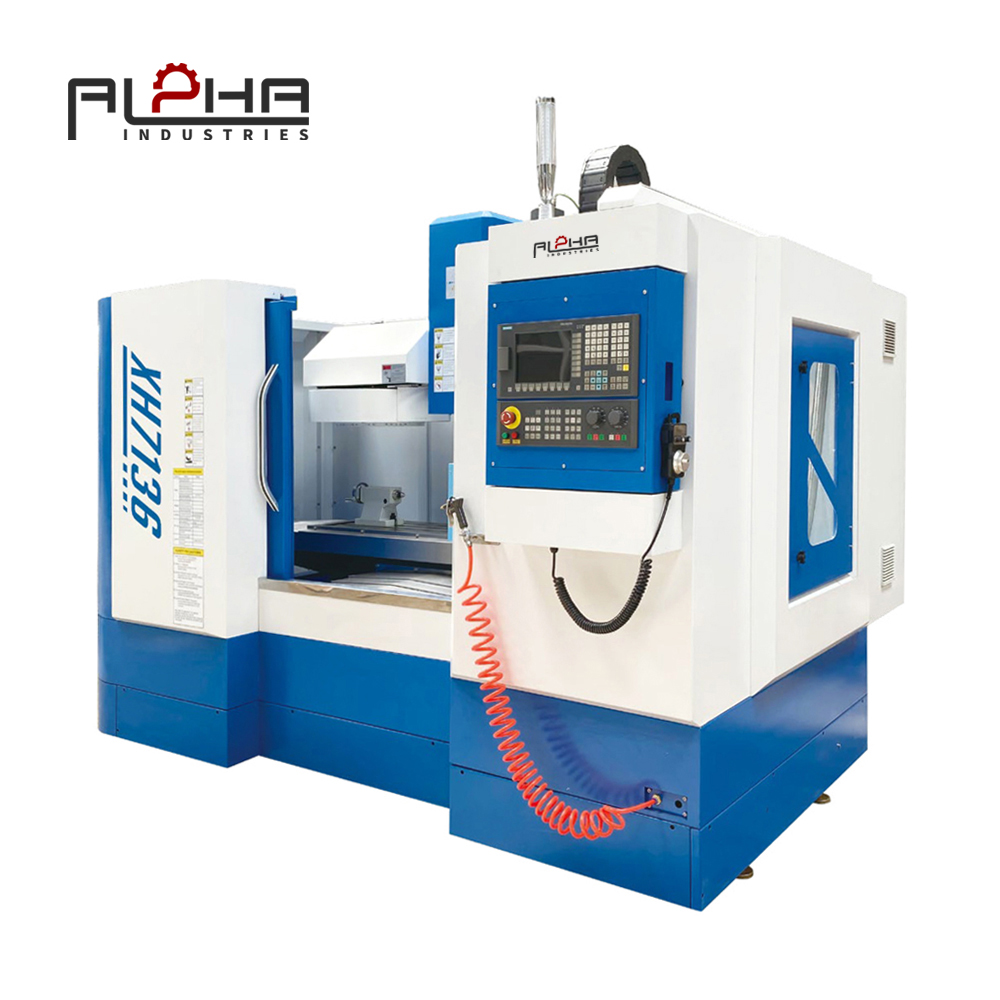

VMC Thermal Stability and Structural Rigidity for High-Precision Industrial Machining

In modern precision manufacturing, thermal stability and structural rigidity are the core factors that truly determine the long-term machining accuracy of a Vertical Machining Center (VMC). While spindle speed and control systems often receive the most attention, real industrial accuracy depends on how effectively a VMC resists heat deformation, vibration, and structural deflection during continuous production.

At Alpha, all VMC machines are engineered with thermal-balanced mechanical structures, high-rigidity cast frames, and intelligent temperature compensation systems, delivering stable micron-level accuracy even under 24/7 heavy-duty production environments.

This article provides a deep technical analysis of VMC thermal stability and structural rigidity technology, its influence on machining precision, and why it has become the key purchasing criterion for high-end manufacturing enterprises.

What Is Thermal Stability in a VMC?

Thermal stability refers to a VMC’s ability to maintain dimensional accuracy despite internal heat generation and environmental temperature changes. Heat is primarily generated from:

-

Spindle rotation at high RPM

-

Servo motors and guideway friction

-

Cutting heat transferred from the workpiece

-

Ambient factory temperature fluctuations

If thermal deformation is not properly controlled, it directly causes:

-

Axis positioning drift

-

Z-axis length variation

-

Tool offset instability

-

Dimensional deviation during long machining cycles

An industrial-grade VMC must therefore integrate structural thermal symmetry, material optimization, and active temperature compensation.

Why Structural Rigidity Determines VMC Machining Accuracy

A rigid machine structure is the physical foundation for precision machining. During cutting, the VMC is exposed to:

-

Dynamic cutting force

-

Tool impact loads

-

High-speed acceleration and deceleration

-

Continuous vibration excitation

If rigidity is insufficient, the result is:

-

Micro-chatter during finishing

-

Tool deflection under load

-

Inconsistent surface roughness

-

Rapid tool wear and reduced life

Alpha VMC machines are designed with high-rigidity closed-frame structures to ensure minimal deformation under extreme cutting loads, maintaining consistent precision across long-term production.

Alpha VMC Thermal Stability Engineering Design

1. High-Rigidity Cast Iron Machine Base

Alpha VMC adopts high-density Meehanite cast iron for the machine bed and column:

-

Excellent vibration absorption

-

Low thermal expansion coefficient

-

High structural damping performance

-

Superior long-term dimensional stability

This prevents accuracy loss caused by structural fatigue and thermal cycling.

2. Symmetrical Thermal Structure Layout

The entire mechanical structure is arranged using thermal symmetry principles:

-

Spindle center aligned with machine mass center

-

Symmetrical guideway distribution

-

Balanced motor placement

This minimizes thermal distortion caused by uneven heat accumulation.

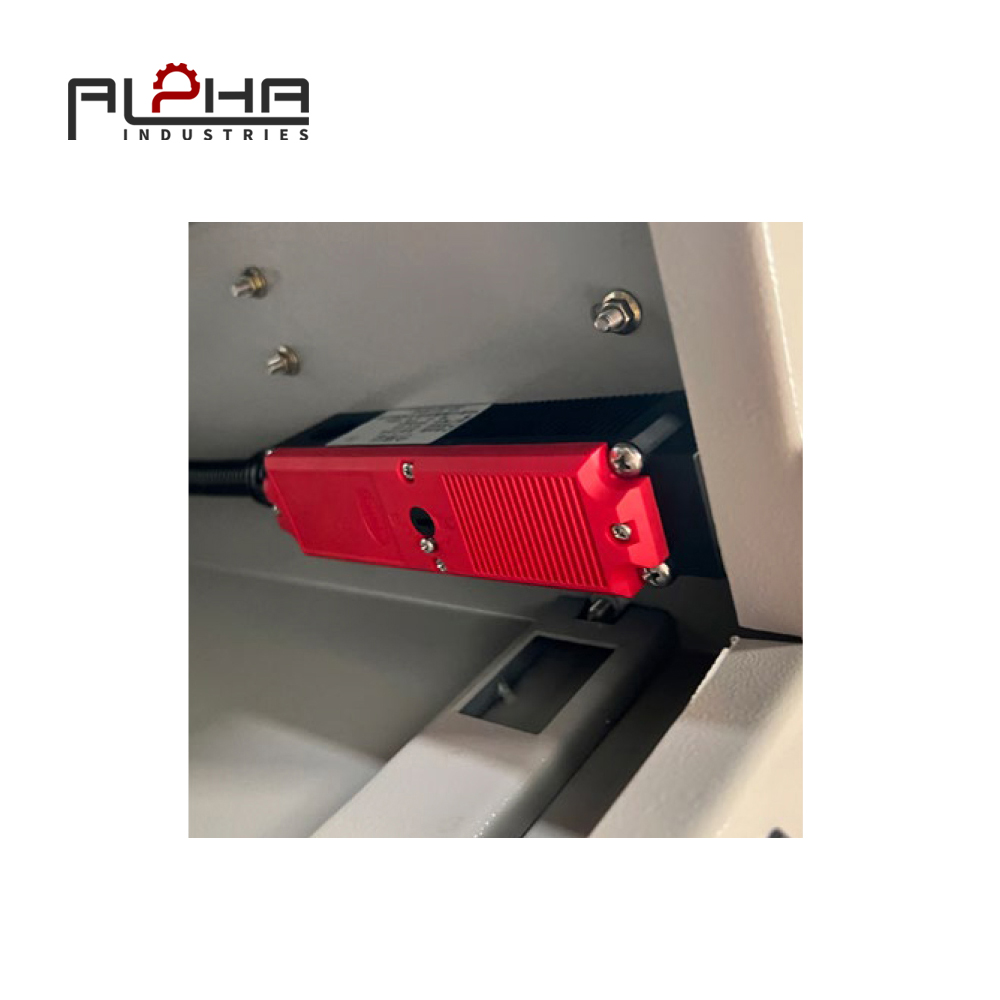

3. Intelligent Temperature Compensation System

Alpha integrates real-time thermal compensation algorithms inside the VMC control system:

-

Temperature sensors monitor spindle, column, and bed temperatures

-

System calculates thermal displacement in real time

-

Automatic position correction is applied to each axis

This keeps machining accuracy stable even during temperature fluctuation of ±10°C in factory conditions.

4. Precision Guideway & Ball Screw Thermal Protection

-

Preloaded linear guideways reduce friction heat

-

High-precision ball screws with hardened shafts

-

Independent lubrication channels

-

Thermal isolation from motor heat sources

This ensures axis accuracy remains stable during continuous rapid feed movement.

Influence of Thermal Stability on Long-Term Machining Accuracy

Without thermal control, a VMC may show:

-

0.02–0.05 mm drift within several hours of operation

-

Dimensional inconsistency across large batch production

-

Tool offset recalibration frequency increase

With Alpha thermal stability technology:

-

Continuous 24-hour machining error ≤ ±0.005 mm

-

Stable part consistency across thousands of pieces

-

Reduced downtime for machine compensation

This directly translates into lower scrap rates and higher yield ratio.

Structural Rigidity & Heavy Cutting Performance

Alpha VMC structural design supports:

-

High torque rough milling on steel and cast iron

-

Deep cavity mold processing

-

Heavy face milling operations

-

High-speed contour finishing on aluminum

Key rigidity-enhancing features include:

-

Box-type reinforced column structure

-

Wide-span linear guideways

-

Thickened ribbed casting design

-

Optimized finite element structural simulation

These ensure high stiffness without sacrificing dynamic response.

Comparison: High-Rigidity VMC vs Conventional VMC

| Performance Item | Alpha High-Rigidity VMC | Conventional VMC |

|---|---|---|

| Thermal deformation | Minimal | Significant |

| Long-term accuracy | High stability | Drift over time |

| Vibration control | Excellent | Moderate |

| Tool life | Extended | Reduced |

| Batch consistency | Very high | Unstable |

Industries Highly Dependent on VMC Thermal Stability

Thermal-stable VMC machines are essential for:

-

Automotive engine parts

-

Precision mold and die manufacturing

-

Aerospace aluminum structural parts

-

Medical metal components

-

High-end electronic aluminum enclosures

In these industries, temperature-induced deviation directly affects assembly precision and product qualification rate.

How Alpha Verifies VMC Thermal and Structural Performance

Each Alpha VMC undergoes strict factory verification:

-

Long-time thermal growth testing

-

Dynamic vibration analysis

-

Heavy cutting load endurance testing

-

Laser interferometer positioning accuracy inspection

-

72-hour continuous machining simulation

Only machines that meet industrial-grade stability standards are approved for shipment.

FAQ

Q1: What causes accuracy loss in a VMC during long machining cycles?

Thermal deformation from spindle heat, axis movement, and cutting heat is the main cause of long-term accuracy drift.

Q2: How does thermal compensation improve VMC precision?

Thermal compensation measures temperature changes in real time and automatically corrects axis positioning errors.

Q3: Is a rigid VMC structure important for heavy cutting?

Yes. High rigidity prevents machine deflection, vibration, and tool chatter under heavy cutting loads.

Q4: Does thermal stability affect tool life?

Yes. Stable thermal conditions reduce tool vibration and uneven wear, significantly extending tool life.

Q5: How long can a thermally stable VMC maintain precision?

With proper design and compensation, industrial-grade VMCs can maintain stable accuracy for 24/7 continuous production.

Why Choose Alpha VMC for High-Stability Machining

At Alpha, thermal stability and structural rigidity are treated as core engineering objectives, not optional features. Every VMC is designed to deliver:

-

Long-term dimensional accuracy

-

Stable batch consistency

-

High tool utilization rate

-

Reduced maintenance frequency

-

Reliable continuous industrial operation

This is why Alpha VMC machines are trusted by manufacturers across automotive, mold, and precision metal industries worldwide.

Call to Action

Looking for a VMC with long-term thermal stability?

Need consistent precision for batch production?

Want reliable performance for continuous industrial machining?

👉 Contact Alpha today to receive a professional VMC solution customized for your production needs.

Explore more Alpha solutions:

-

Vertical Machining Center Series:

https://alpha-cnc.com/products/vmc-series -

Industrial CNC Lathe Machines:

https://alpha-cnc.com/products/cnc-lathe-slant -

High-Precision Press Brake Machines:

https://alpha-cnc.com/products/cnc-press-brake-series -

Fiber Laser Cutting Systems:

https://alpha-cnc.com/products/laser-cutting