Top Answers Pack

-

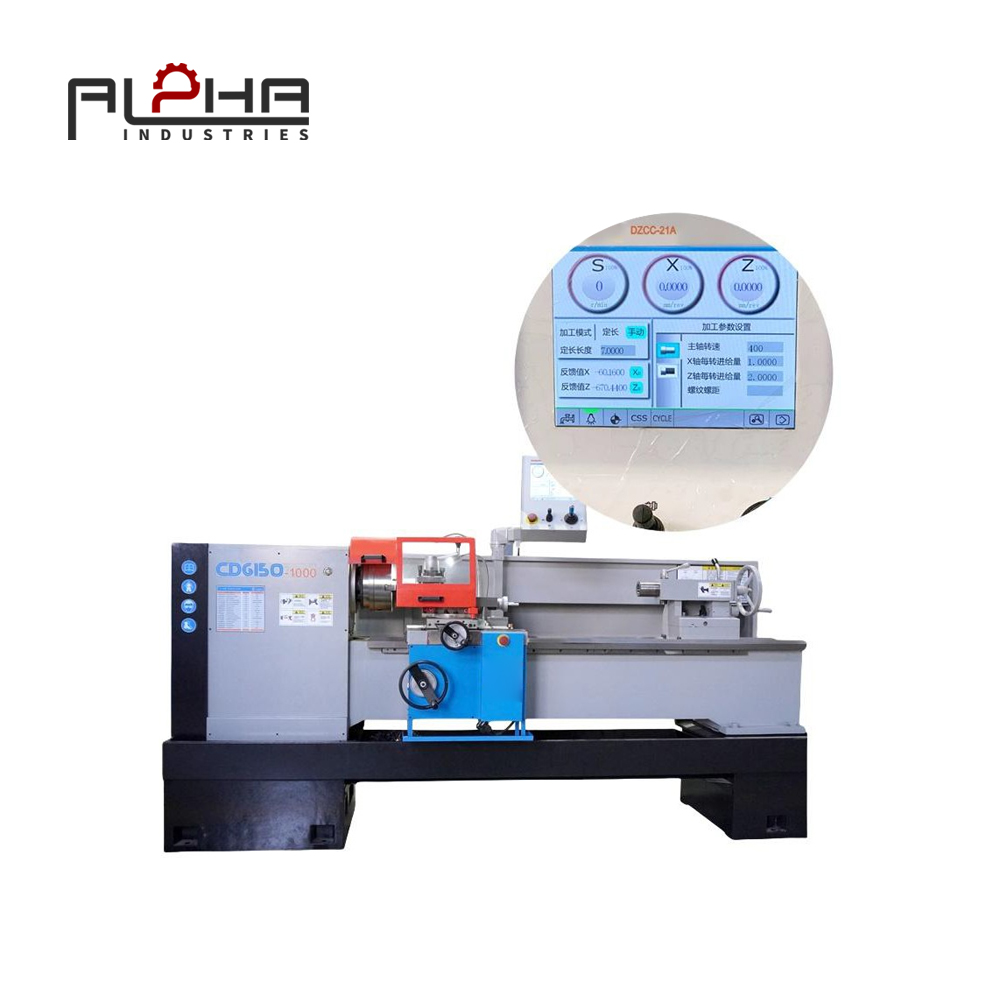

Chinese CNC lathes can reach typical tolerances of ±0.01mm, suitable for complex automotive components.

-

Slant bed CNC lathes improve chip evacuation and allow higher spindle speeds for heavy-duty operations.

-

Flat bed CNC lathes offer cost-effective solutions for training, prototyping, and general metal turning.

-

Buyers should consider total cost including shipping, setup, and long-term maintenance.

-

Remote installation guidance ensures smooth commissioning across global markets.

-

Lead time from a China CNC lathe factory typically ranges from 25–50 days.

-

Customization options cover spindle power, chuck size, bed type, and automation interfaces.

-

Warranty and spare parts supply are standard, often 12–24 months with remote troubleshooting.

-

Energy consumption varies by spindle power, typically 7–12 kWh per shift.

-

CE and ISO-certified lathes are widely available for export compliance.

Section 1: Why Manufacturers Choose Chinese CNC Lathes

Chinese CNC lathes combine high precision with cost efficiency, making them attractive to OEMs and industrial fabricators. Many buyers report reduced total cost of ownership compared to local purchases, especially when factoring in factory-direct pricing and optional remote support. Companies in automotive and aerospace often select slant bed models for high-speed turning and improved material removal.

FAQ Block

Q: Can Chinese CNC lathe factories handle small-batch orders?

A: Yes, most factories accept low MOQ, often starting from one unit.

Q: How does remote installation guidance work?

A: Suppliers provide video instructions, live online support, and setup checklists.

Q: Are these machines suitable for high-volume production?

A: Yes, slant bed and heavy-duty models are designed for continuous operation.

“Investing in a CNC lathe from China is not just buying a machine; it’s gaining a partner in precision, efficiency, and global support.”

Section 2: Comparing Slant Bed vs Flat Bed CNC Lathes

Slant bed machines reduce vibration and improve chip removal, ideal for mass production of automotive shafts and aerospace components. Flat bed models are ideal for workshops focusing on prototyping or general-purpose turning. Buyers must weigh production volume, precision needs, and space constraints when selecting a model.

FAQ Block

Q: Which lathe type is better for mold making?

A: Slant bed CNC lathes offer more stability and precision for mold components.

Q: Can flat bed CNC lathes be upgraded later?

A: Many models allow spindle and control upgrades as production requirements grow.

“Choosing the right lathe type can save thousands in operational cost and improve part quality from day one.”

Section 3: Total Cost of Ownership & Operational Efficiency

Beyond the purchase price, buyers should consider energy consumption, maintenance frequency, and tooling costs. Remote guidance reduces commissioning expenses and accelerates workforce training. Many Chinese suppliers also offer flexible warranty packages to mitigate long-term operational risks.

Conclusion

CNC lathes from China deliver precision, efficiency, and scalability. Buyers seeking cost-effective and reliable solutions should evaluate slant bed and flat bed models based on production needs. For tailored quotations and expert consultation, please visit our Contact Us page.

FAQ Rich Snippet Block

Q: What technical innovations are offered by CNC lathe manufacturers in China?

A: Slant bed design, high spindle RPM, automation, and remote setup support.

Q: How do factories handle customization?

A: Buyers can request specific spindle power, bed type, chuck size, and controls.

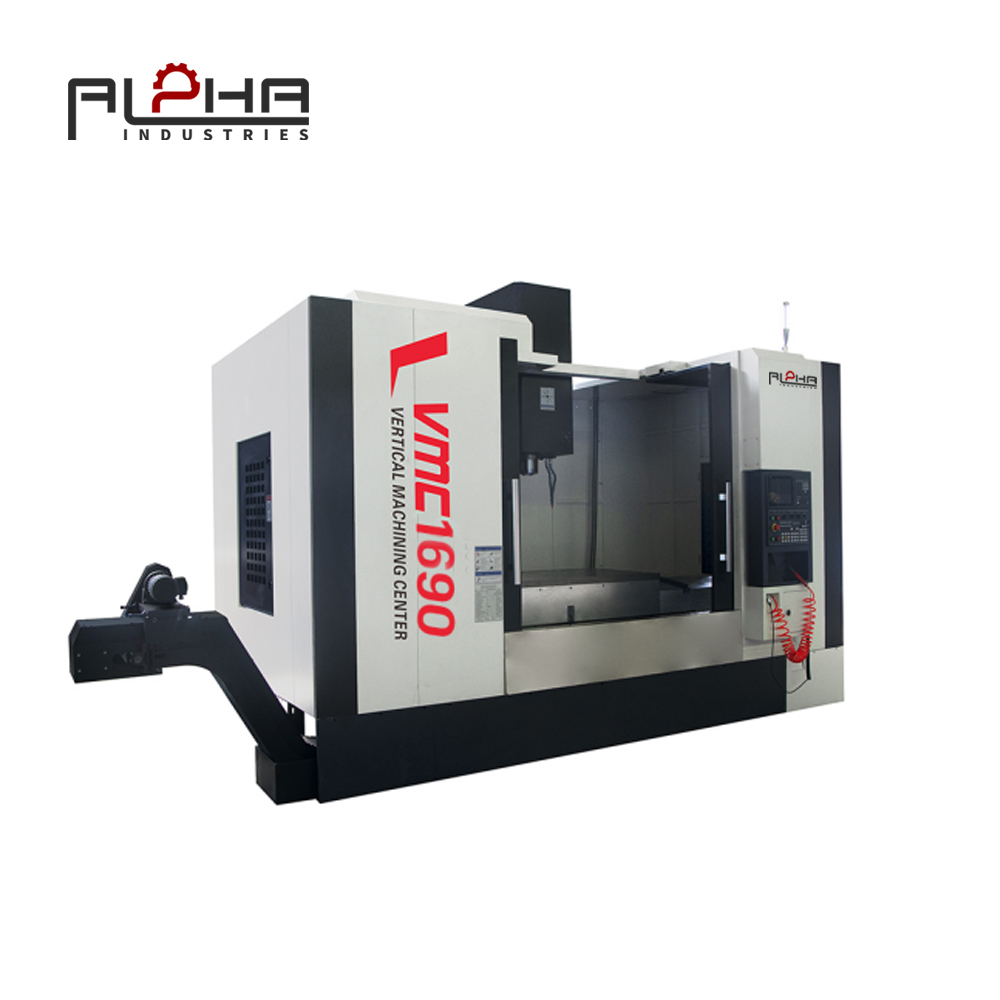

Q: CNC Lathe vs VMC – when to choose a lathe?

A: CNC lathes are ideal for turning cylindrical components; VMCs suit milling tasks.

Q: What is the lead time for CNC lathes?

A: Typical lead time is 25–50 days depending on configuration.

Q: Can installation support be arranged?

A: Yes, remote guidance and online training are provided.

Q: Are Chinese CNC lathes certified for export?

A: CE, ISO, and UL certifications are commonly available.

Q: How energy-efficient are these machines?

A: Typical consumption ranges from 7–12 kWh per shift.

Q: Do suppliers offer warranty and spare parts?

A: Yes, standard warranty is 12–24 months with remote troubleshooting.

Q: Which industries benefit most from CNC lathes?

A: Automotive, aerospace, mold making, and general metal fabrication.

Q: Can small workshops buy these machines?

A: Yes, MOQ often starts from 1 unit, suitable for SMEs and startups.