Introduction to Cylindrical Grinding Machine

External cylindrical grinding machines , also known as cylindrical grinders or OD grinders , are one of the most important precision machining tools in the industry. Alpha specializes in designing and manufacturing advanced grinding machines to achieve exceptional precision, superior surface quality, and long-term reliability.

Explore Alpha's complete product line here ›

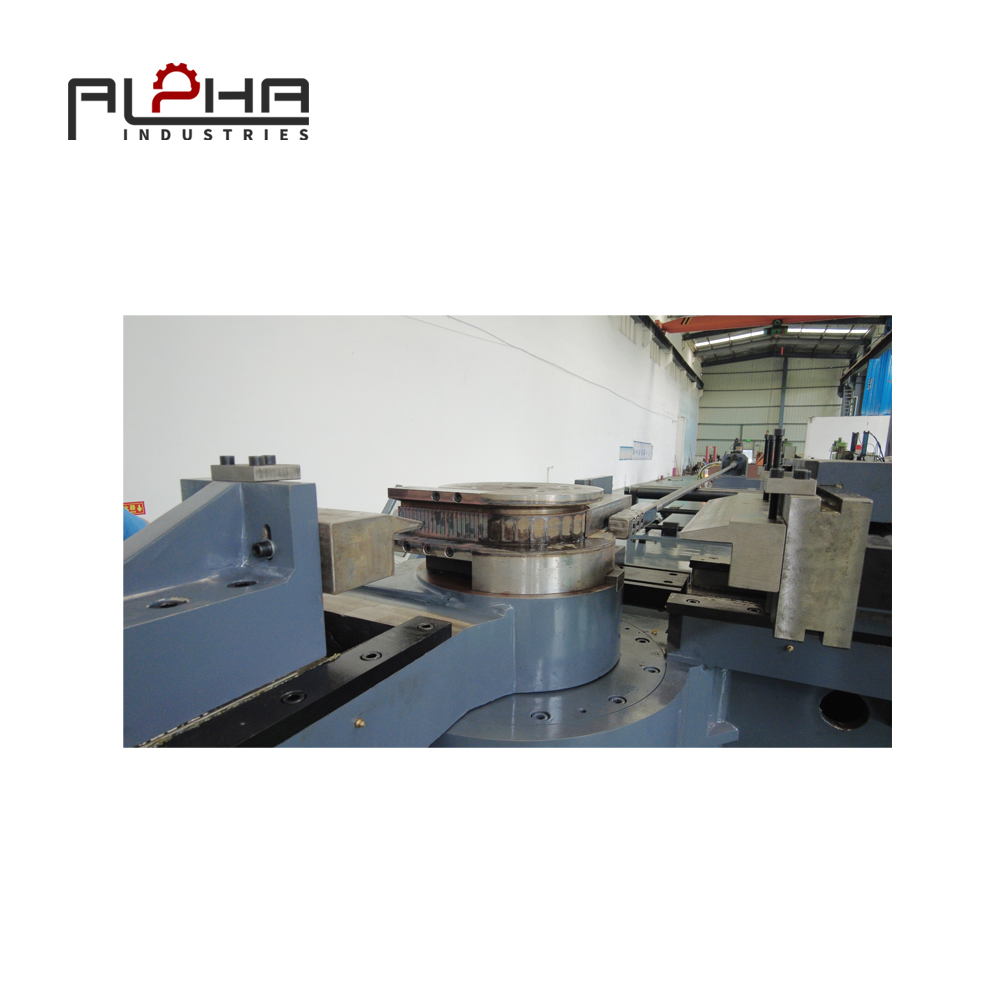

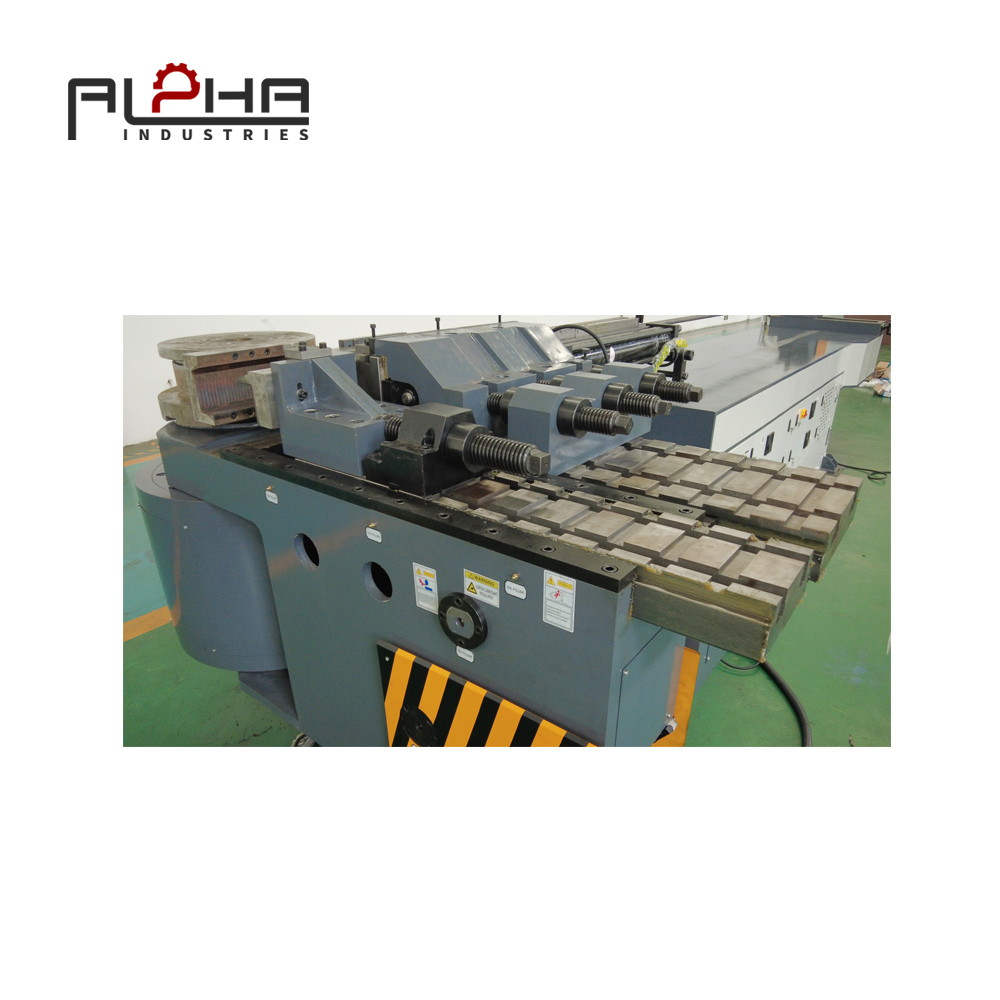

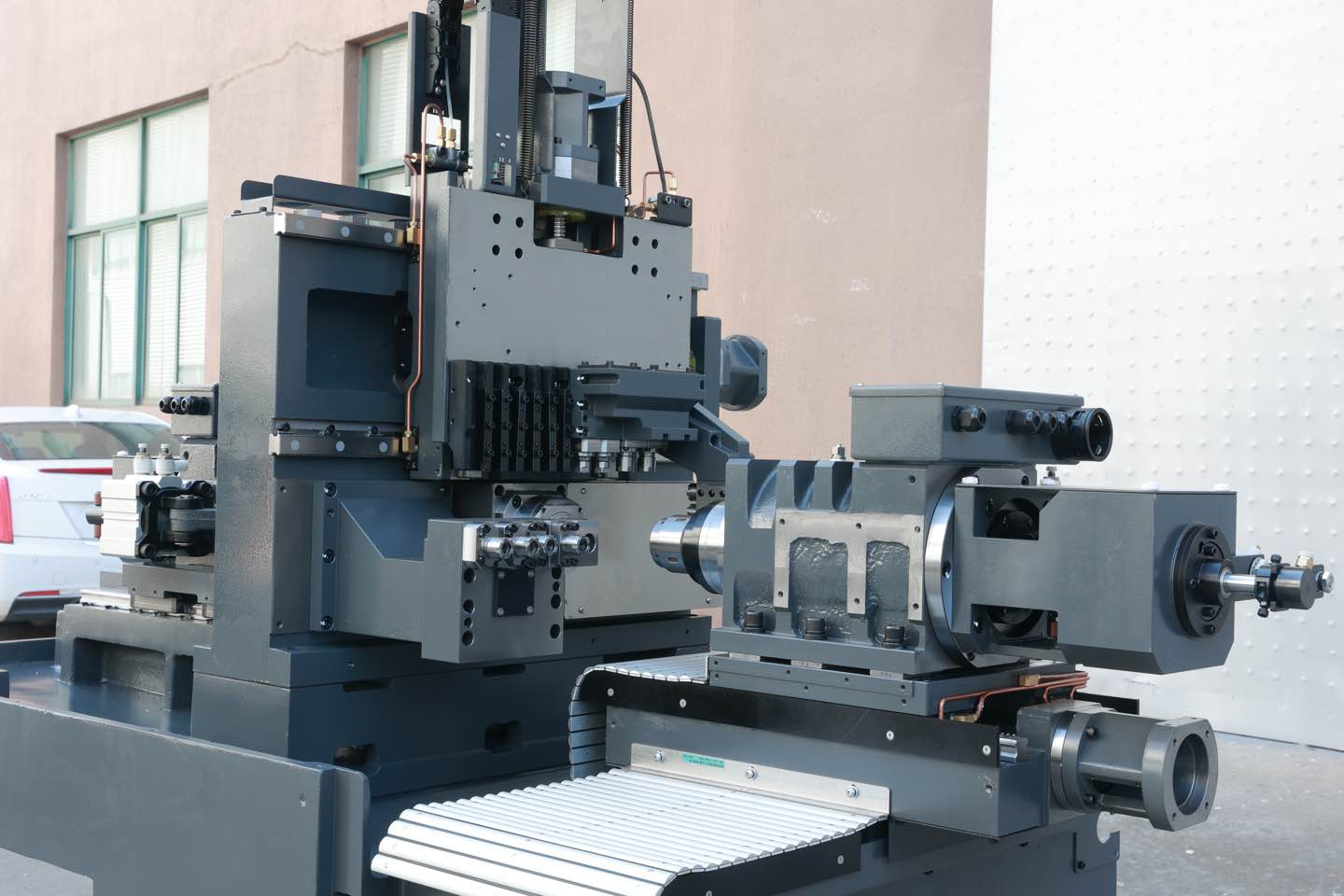

Key features of the Alpha cylindrical grinding machines

High-Precision Performance – Alpha grinders achieve the micron-level tolerances required for demanding applications.

Superior surface finish – smooth, accurate results with consistent quality.

Durability and stability – Alpha machines feature a rigid bed and vibration-absorbing structure.

Automation options – CNC controlled versions support large-scale production with minimal errors.

Versatile – Suitable for use on steel, stainless steel, cast iron and hardened alloys.

Cross-industry applications

Alpha's cylindrical grinding machines are widely used in:

Automotive manufacturing – shafts, gears and transmission components.

Aerospace – Precision parts with tight tolerances.

Tool and die industry – punches, dies and cutting tools.

Heavy machinery – rollers, spindles and large cylindrical parts.

Advantages of choosing Alfa cylindrical grinding machine

Stable accuracy and repeatable results.

Superior surface finish extends part life.

Capable of handling both small and large cylindrical parts.

Reduce operator dependence through CNC automation.

Backed by Alpha's engineering expertise and global support.

View more Alpha Grinding Solutions ›

Technical aspects of cylindrical grinding

Grinding wheel options – Aluminum oxide, CBN or diamond abrasives.

Cooling System – Efficient coolant supply to reduce heat and extend wheel life.

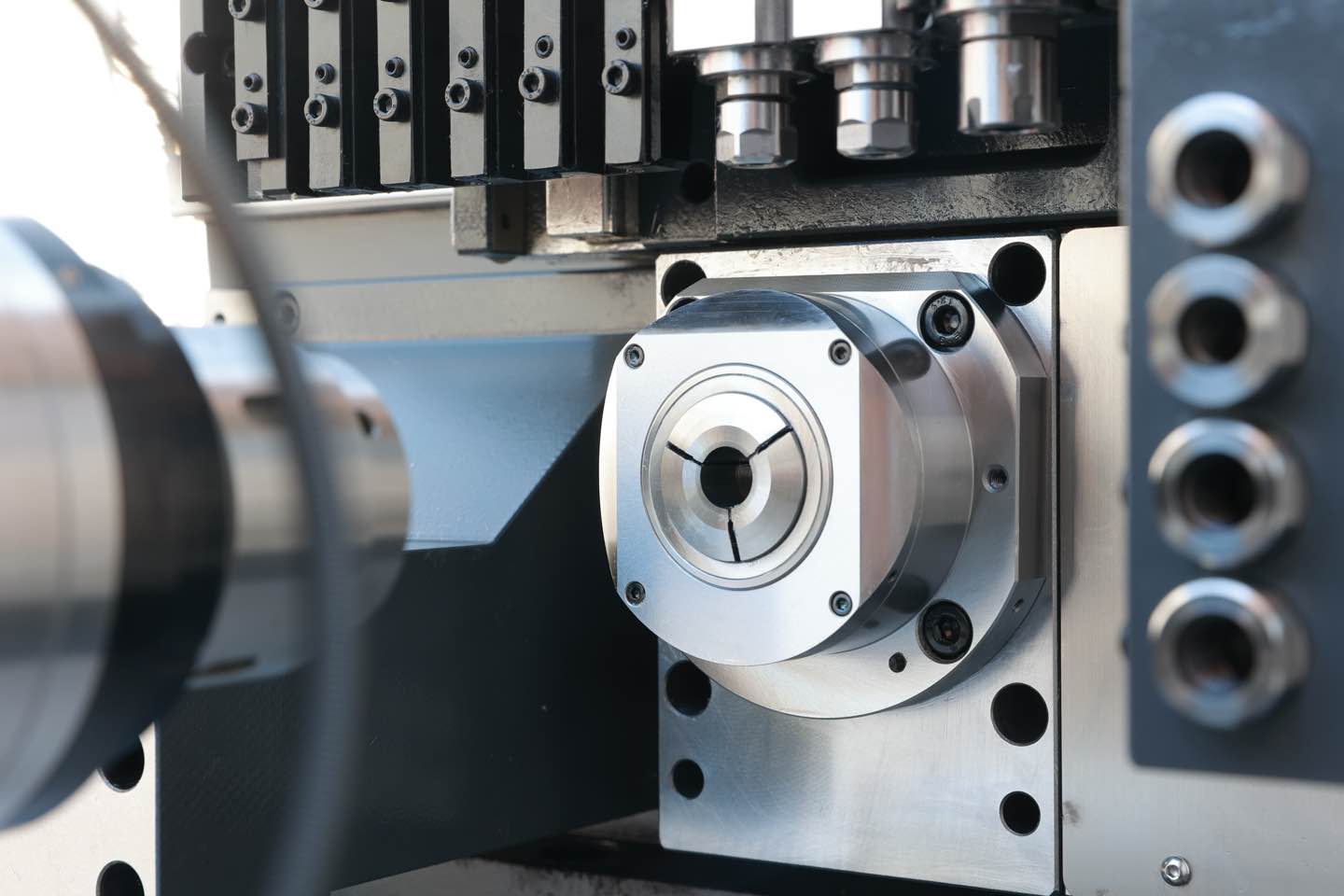

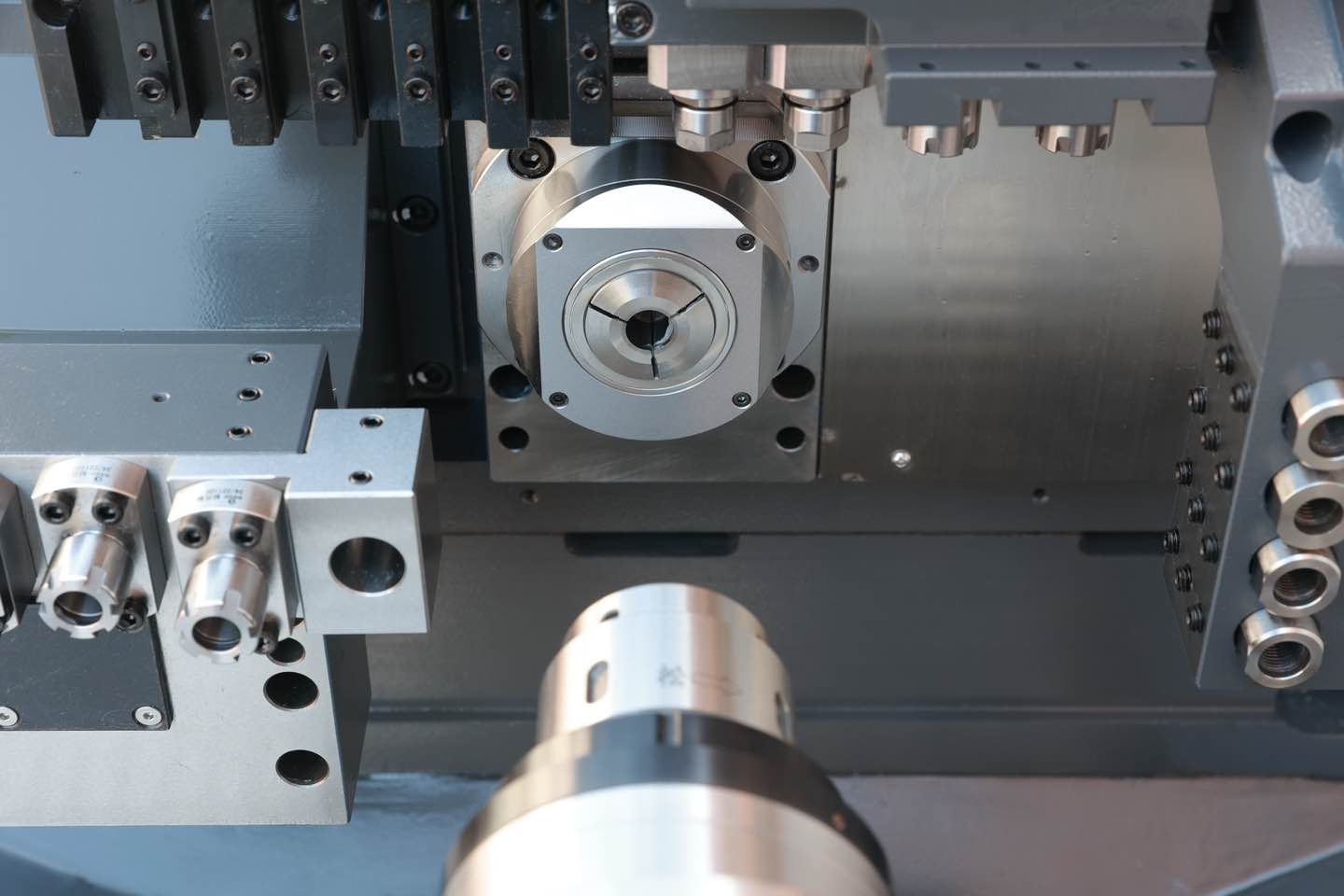

Workholding methods – between centers or using a chuck for precise alignment.

Adjustable speed and feed - to accommodate varying materials and tolerances.

Frequently Asked Questions about Cylindrical Grinding Machines

1. What is a cylindrical grinder?

It is a machine tool for precision grinding the outer surface of cylindrical parts.

2. How does the Alpha external grinder work?

The workpiece rotates between centers or in a chuck while the grinding wheel removes material to achieve the desired size and surface finish.

3. Which industries use Alpha cylindrical grinding machines?

Automotive, aerospace, tool and heavy machinery industries.

4. What materials can be processed by cylindrical grinding?

Steel, stainless steel, hardened alloys and non-ferrous metals.

5. What is the difference between external grinding and internal grinding?

External grinding is used to form the outside diameter, while internal grinding is used to form the bore and inside surfaces.

Internal linking suggestions

Call to Action (CTA)

Looking for a high-precision cylindrical grinding machine ?

Contact Alpha today to learn about our full line of advanced grinding machines designed for industrial excellence.