Vertical Machine Center in Automotive Manufacturing

The automotive industry requires high-precision, high-efficiency machining for mass production of components such as engine blocks, transmission housings, brake parts, and steering components. A Vertical Machine Center (VMC) combines speed, rigidity, and automation to ensure consistent part quality while meeting the large-volume demands of automotive production.

High-Efficiency Machining for Large Batches

Automotive manufacturing emphasizes cycle time reduction. VMCs equipped with high-speed spindles, rapid tool changers, and optimized feed rates significantly reduce machining time. For engine parts and drivetrain components, this results in shorter production cycles and increased output without compromising accuracy.

Structural Rigidity for Durable Precision

Automotive parts often require tight tolerances under heavy loads. VMCs feature cast-iron bases, rib-reinforced columns, and pre-tensioned ball screws, ensuring vibration-free machining. This structural rigidity maintains long-term dimensional accuracy even during continuous operation in large-scale production lines.

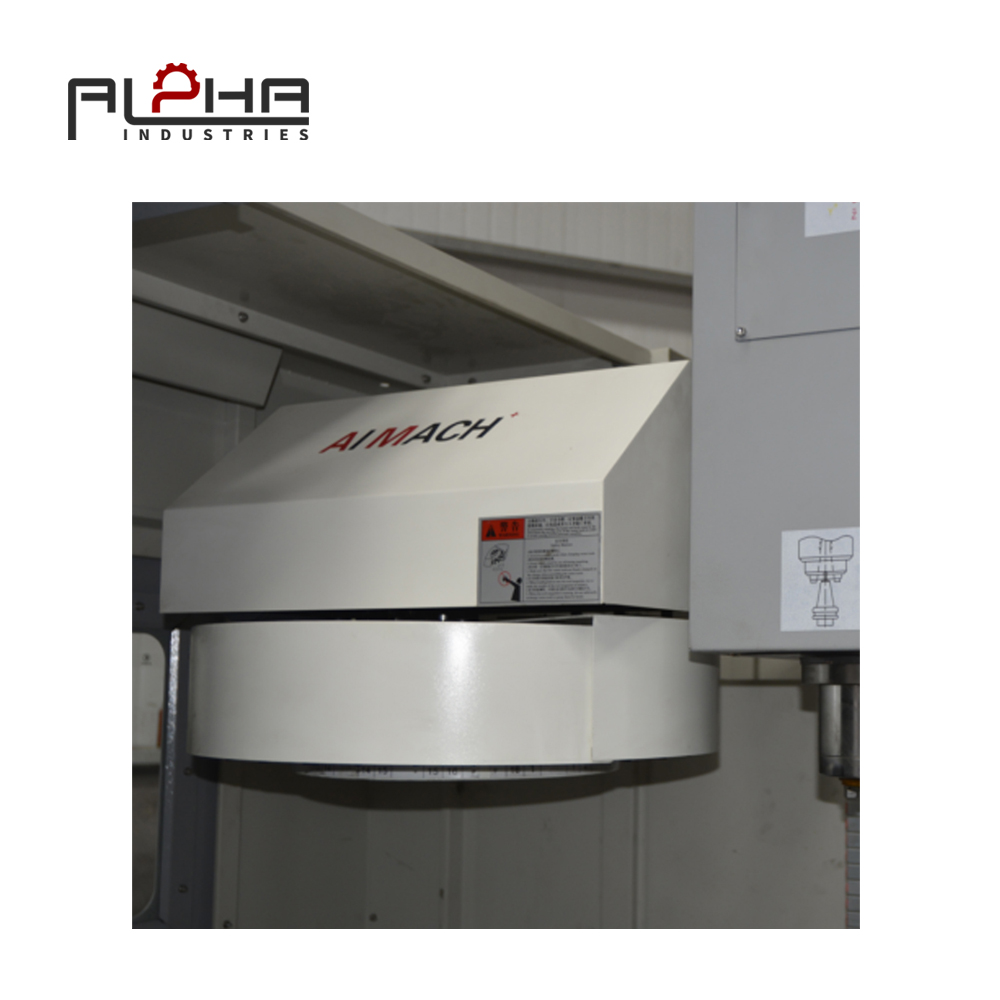

Spindle and Tooling Flexibility

Automotive components range from lightweight aluminum housings to hardened steel gears. VMCs use variable-speed, torque-stable spindles that adapt to different materials. Combined with Automatic Tool Changers (ATC) holding 40+ tools, the machine ensures seamless transitions between drilling, milling, and tapping operations required in automotive machining.

Multi-Axis Capability in Complex Part Geometry

Automotive components, such as cylinder heads and suspension parts, require machining across multiple surfaces. VMCs with 4th and 5th-axis rotary tables allow simultaneous machining, eliminating multiple setups and reducing cumulative error. This ensures consistent quality and reduces production bottlenecks.

Cooling Systems for Continuous Production

Automotive production involves long machining cycles and abrasive materials. VMCs integrate through-spindle coolant delivery, flood cooling, and air-oil lubrication systems to maintain cutting efficiency, extend tool life, and prevent overheating, ensuring uninterrupted operation.

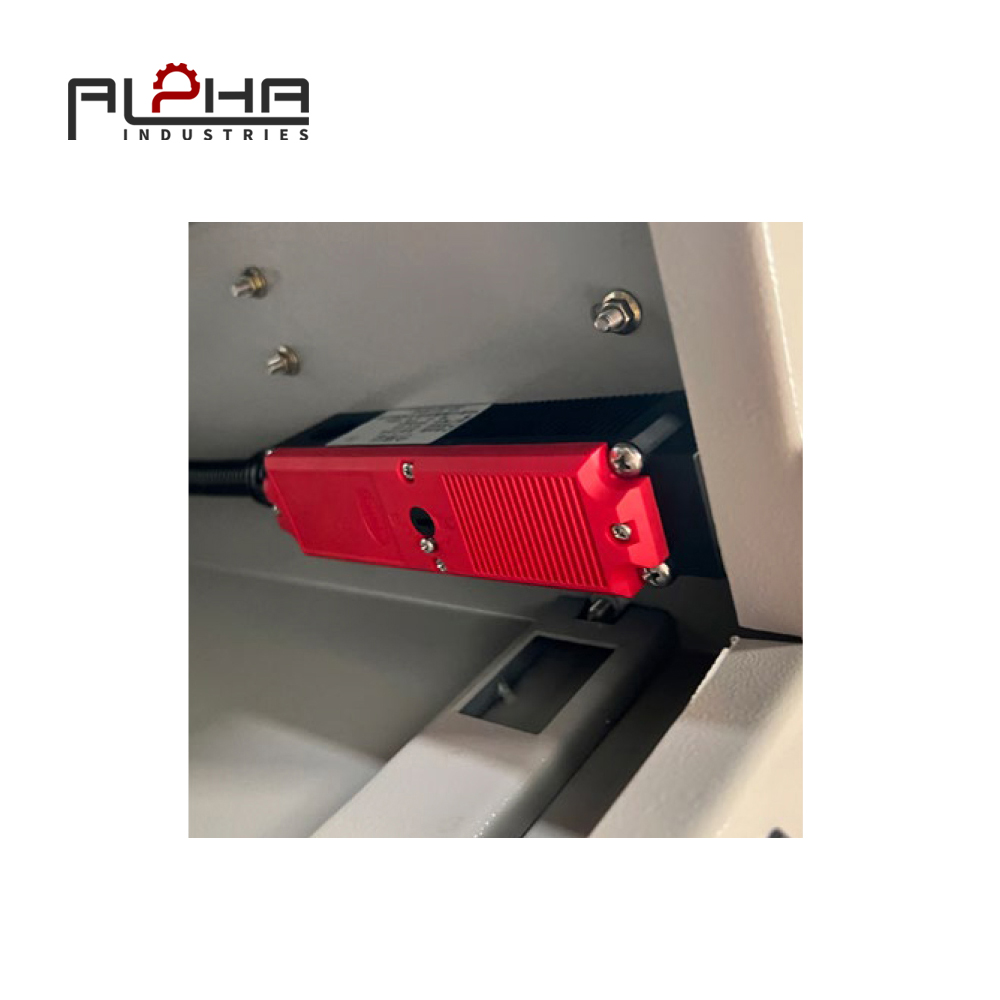

Automation and Mass Production Consistency

Modern automotive plants demand automation and repeatability. VMCs integrate robotic part loaders, tool monitoring systems, and in-process probing, enabling 24/7 production with minimal operator supervision. Automated measurements ensure every automotive part meets quality standards, reducing rework and scrap rates.

FAQ – People Also Ask

1. Why is a Vertical Machine Center important for automotive manufacturing?

VMCs provide high-speed, accurate machining that supports large-batch automotive production while ensuring consistent part quality.

2. What automotive parts can be produced using a Vertical Machine Center?

VMCs are used for engine blocks, cylinder heads, transmission housings, brake components, and precision gears.

3. How do VMCs maintain consistency in mass production?

Through rigid machine construction, ATC systems, and in-process probing, VMCs deliver repeatable accuracy across thousands of parts.

4. Can VMCs handle both aluminum and steel automotive parts?

Yes, VMCs are designed with variable spindle speeds and coolant systems to efficiently machine both lightweight alloys and hardened steels.

5. How do Vertical Machine Centers reduce automotive production costs?

By combining automation, rapid tool changes, and multi-axis machining, VMCs lower cycle times and labor costs, improving overall production efficiency.