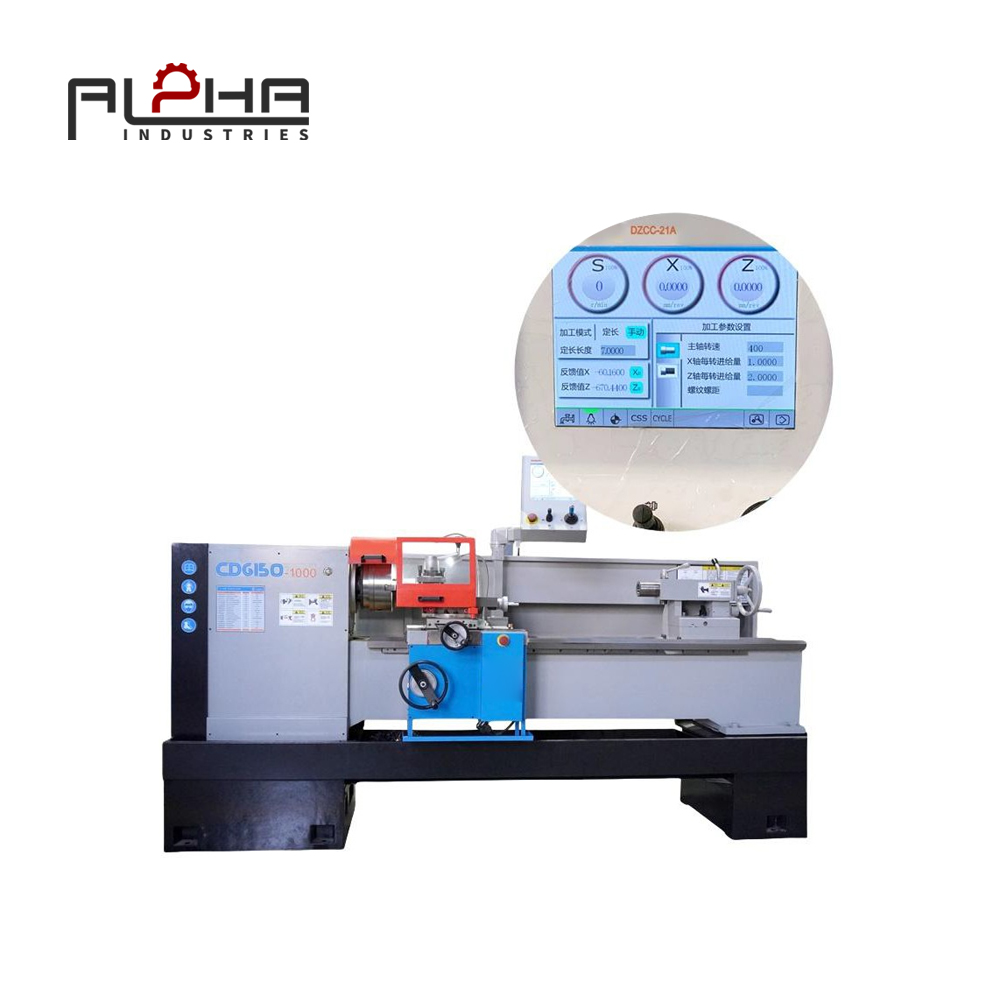

Alpha Heavy-Duty Lathe Machines: Strength Meets Accuracy

At Alpha, we specialize in manufacturing high-rigidity lathe machines that deliver precise performance even under tough workloads. Designed for heavy-duty turning, our lathe machines are ideal for industries demanding consistent accuracy, long service life, and adaptability to various metal components.

Our machines are engineered with a focus on stability, tool flexibility, and enhanced operational safety, helping you meet tight tolerances and production deadlines.

Main Features of Alpha Lathe Machines

-

Reinforced One-Piece Bed Structure

Provides enhanced vibration absorption and long-term dimensional stability. -

High-Torque Spindle Drive

Supports high-load cutting with smooth speed transitions, ideal for processing large-diameter workpieces. -

Wide Carriage and Cross Slide

Allows for improved cutting support and surface finish quality in both roughing and finishing. -

Rapid Feed Mechanism

Enables faster positioning and tool changeover, boosting overall productivity. -

Multi-Functional Tailstock

Supports drilling, reaming, and long-shaft turning with adjustable pressure.

Lathe Machine Categories Offered

Conventional Engine Lathe– Classic design with mechanical controls and feed gears.

Bench Lathe– Compact structure, ideal for hobbyists, repair shops, and training institutions.

Heavy-Duty Floor Lathe– Suitable for large shafts, pipe flanges, and high-inertia components.

Gap Bed Lathe– Enables turning of oversize parts by removing bed section.

Typical Application Fields

-

Steel Processing Workshops

-

Shipbuilding & Offshore Fabrication

-

Mining & Heavy Equipment Industry

-

Automotive Shaft and Hub Manufacturing

-

Precision Repair Centers

-

Machining Education & Vocational Training

Why Choose Alpha Lathe Machines?

-

Industrial-Level Build:Heavy cast iron foundation ensures structure rigidity even in rough machining.

-

Accurate, Repeatable Performance:Precision testing includes run-out inspection, taper accuracy, and thread pitch consistency.

-

Global Engineering Support:24/7 service response, detailed operation manuals, and overseas dealer networks.

-

Custom-Tailored Solutions:OEM and ODM options available for batch orders and special components.

FAQs:

1. What materials can Alpha heavy-duty lathes handle?

Alpha lathes are built to process mild steel, stainless steel, alloy steel, cast iron, aluminum, and copper with appropriate tooling.

2. How does the gap bed function work?

The gap section of the bed can be temporarily removed to accommodate larger-diameter workpieces, offering flexibility without changing the overall machine layout.

3. Can I install a digital readout (DRO) on your machines?

Yes, most Alpha models are compatible with 2-axis or 3-axis DRO systems, which we can install prior to shipment upon request.

4. How do Alpha lathes perform under long production cycles?

With heat-treated components and wear-resistant guideways, Alpha lathes are designed for 24/7 production without compromising accuracy.