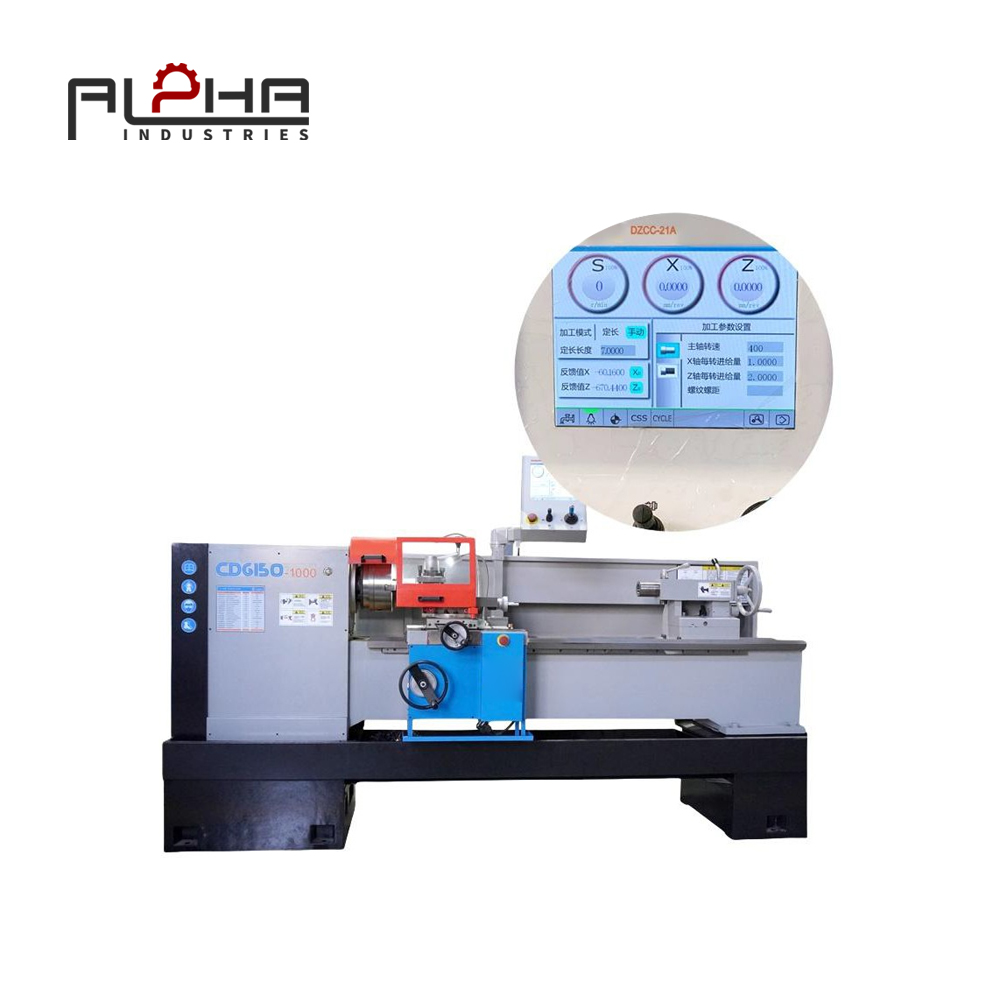

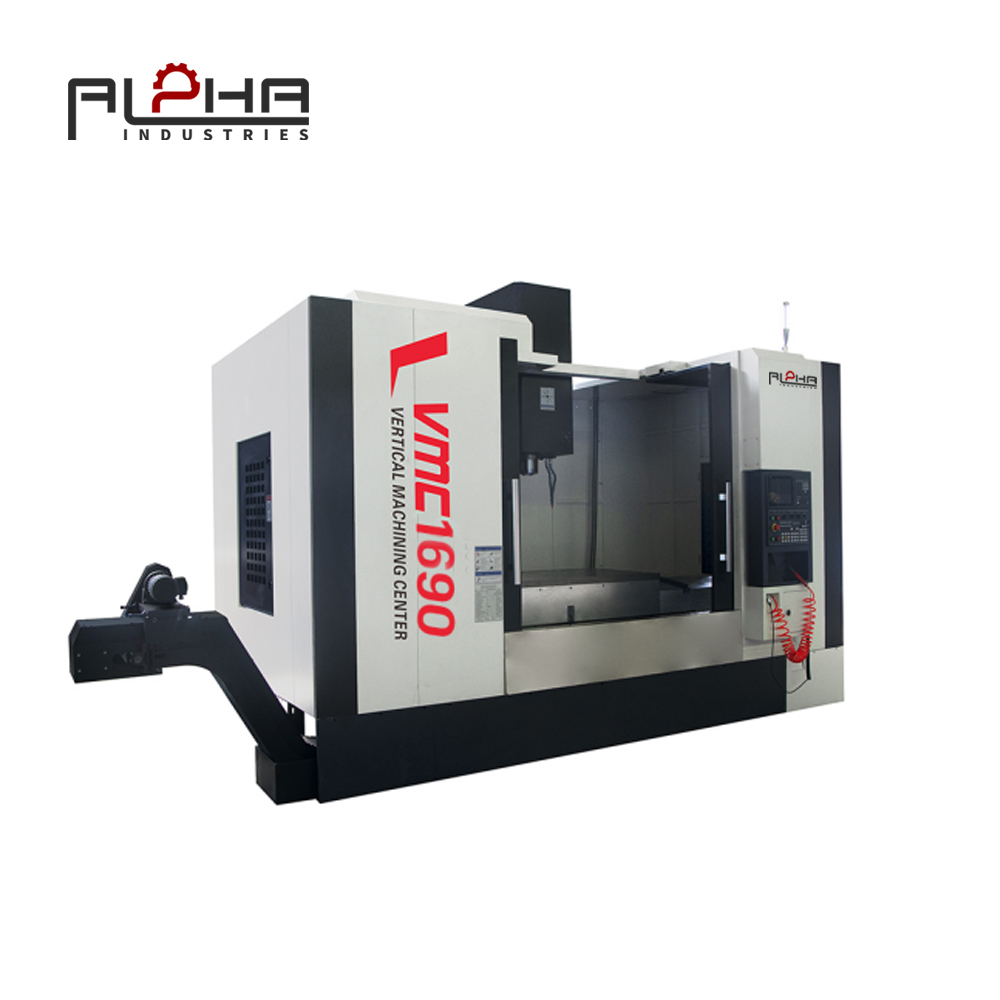

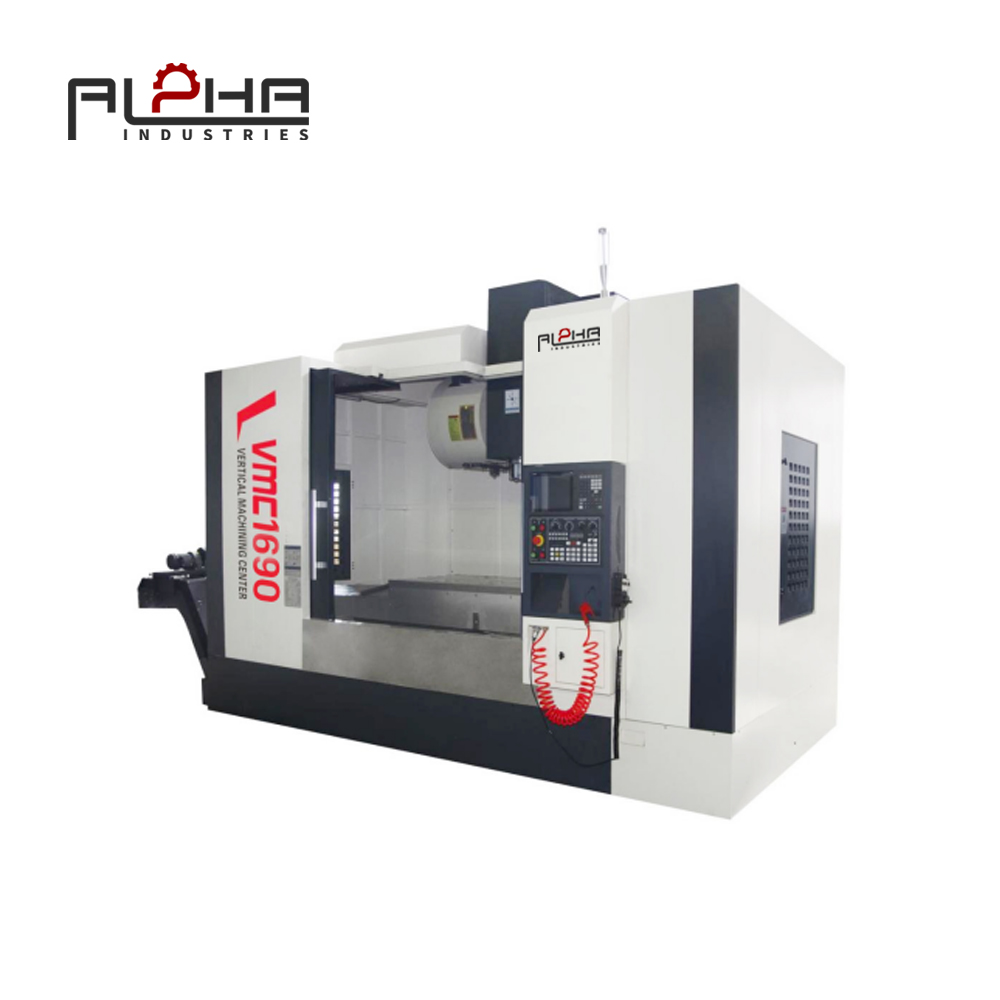

Alpha is a trusted manufacturer of high-performance lathe machines tailored for precision metalworking tasks across a wide range of industries. Engineered for reliability, versatility, and high-speed operation, our lathes meet the growing demands of global customers seeking durable and accurate machining solutions.

Whether you're machining shafts, flanges, or complex workpieces, Alpha's lathe series provides superior rigidity, smooth operation, and outstanding surface finish for both small-scale workshops and industrial mass production lines.

Features of Alpha Lathe Machines

-

Robust Structure: Our lathe beds are made from high-grade cast iron with precision ground surfaces and reinforced rib structures for superior vibration resistance and stability.

-

Precision Spindle System: Supported by high-speed bearings, the spindle delivers stable rotation, low run-out, and excellent cutting accuracy.

-

Easy Operation: Ergonomic handwheels, clear scale indicators, and an intuitive control panel simplify setup and adjustment.

-

Versatile Tooling: Compatible with a variety of turning tools, chucks, and tailstocks to support facing, threading, grooving, and taper turning.

-

Gearbox Options: Choose from manual or automatic feed gearboxes to match your production needs and operator preferences.

Types of Lathes We Offer

-

Engine Lathes: Ideal for general-purpose metal turning with excellent strength and precision.

-

Bench Lathes: Compact and versatile, perfect for small workshops, schools, and repair tasks.

-

Heavy-Duty Lathes: Designed for large-diameter and long workpieces with enhanced spindle torque and bed width.

-

Slant Bed CNC Lathes: For automated turning applications requiring repeatability and efficiency.

Application Industries

Alpha lathe machines are widely used in:

-

Automotive Manufacturing

-

Aerospace Component Machining

-

Energy Equipment

-

Tool & Die Production

-

General Engineering Workshops

-

Educational Institutions

Why Choose Alpha Lathe Machines?

-

Reliable Quality Control: Every Alpha lathe is tested with precision gauges and dynamic cutting simulations.

-

Export-Ready Design: Compliant with CE, ISO, and global safety standards.

-

Global Support: Fast delivery, technical support, and spare parts for over 35+ countries.

FAQs About Lathe Machines

1. What is a lathe machine used for?

A lathe is used for shaping metal (or wood) by rotating the workpiece against a cutting tool. Common operations include turning, facing, threading, and drilling.

2. How do I choose the right lathe machine for my workshop?

Consider your machining volume, material types, workpiece size, and available workspace. Bench lathes are ideal for light tasks; heavy-duty or CNC lathes suit high-precision, high-volume applications.

3. What materials can Alpha lathes process?

Alpha lathes can process a variety of materials, including mild steel, stainless steel, aluminum, brass, and plastic, depending on tooling and spindle setup.

4. What safety features are built into Alpha lathes?

Emergency stop buttons, spindle guards, overload protection, and ergonomic control layouts ensure operator safety during all stages of machining.

5. Can Alpha customize lathe specifications?

Yes. We provide OEM/ODM services to meet special requests, including bed length, spindle bore size, electrical configurations, and automation options.