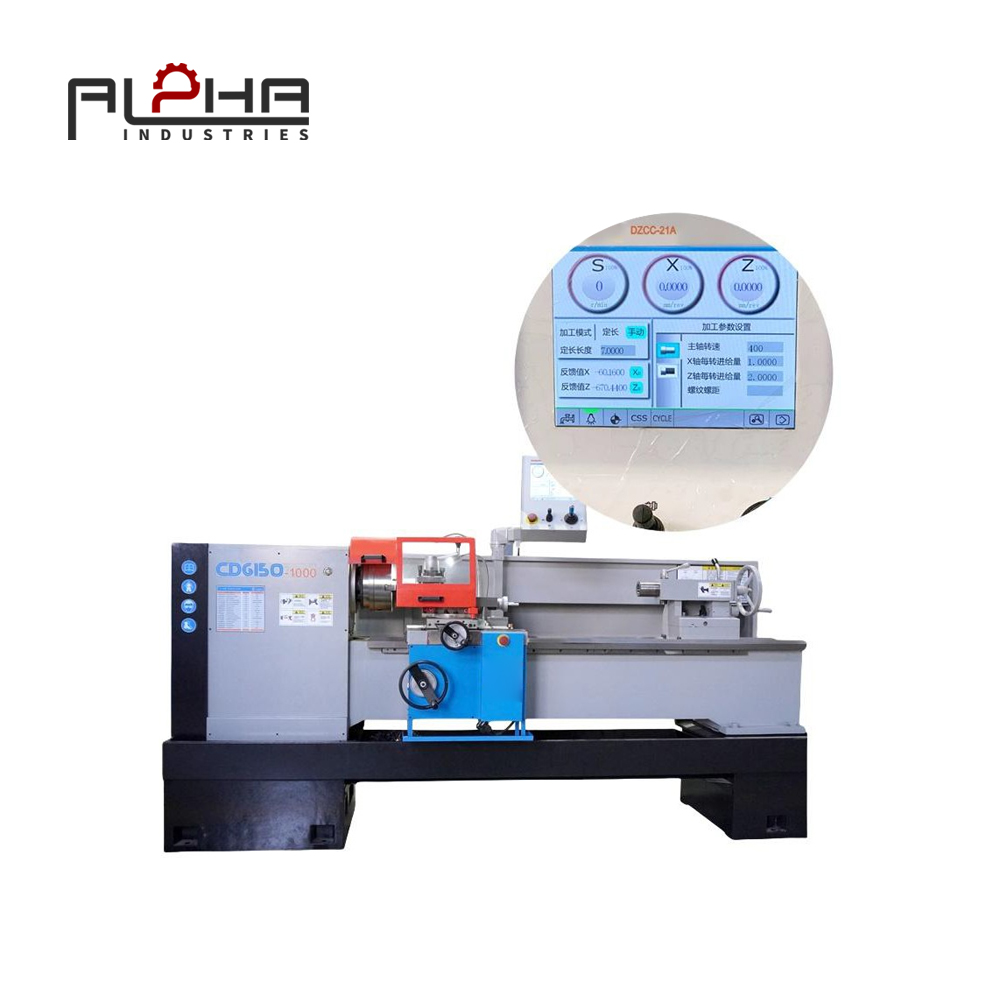

Industrial Lathe Machines Built to Last — By Alpha

Alpha designs and manufactures precision lathe machines tailored for the modern industrial environment. Whether you're machining large-diameter flanges, threading long shafts, or performing fine finishing tasks, Alpha’s lathe series offers superior rigidity, stable operation, and unmatched durability.

Our machines are optimized for continuous duty cycles in demanding metalworking sectors, ensuring productivity without compromise.

Core Features of Alpha Lathe Machines

-

High-Tensile Cast Iron Bed: Rigid bed construction ensures long-term geometric accuracy and vibration damping during heavy cuts.

-

Accurate Spindle Assembly: Precision bearings and hardened spindle components deliver high-speed stability and minimal runout.

-

Efficient Chip Removal: Wide carriage surfaces and sloped chip trays facilitate quick and clean swarf removal.

-

Multi-Speed Gearbox: Broad range of spindle speeds and feeds allow machining of soft aluminum to hardened steel.

-

Operator Safety & Comfort: Emergency stops, full splash guards, and ergonomic hand controls are integrated into every model.

Model Range and Applications

Alpha lathe machine series includes:

-

Bench Lathe: Lightweight, accurate, and space-saving – suitable for schools, R&D labs, and repair centers.

-

Engine Lathe: Perfect for general-purpose use in manufacturing, repair, and prototyping.

-

Heavy-Duty Industrial Lathe: For high-volume operations, long workpieces, and large diameters – ideal for energy, shipbuilding, and mining industries.

-

Optional DRO System & Tool Posts: Enhance measurement precision and cutting efficiency with optional accessories.

Industries Served by Alpha Lathe Machines

Mechanical Parts Production

Oil & Gas Pipeline Machining

Shipbuilding and Marine Shaft Turning

Aerospace Component Manufacturing

Mining Equipment Fabrication

Precision Repair and Maintenance Shops

Why Customers Choose Alpha Lathe Machines

-

Industrial-Grade Precision: All machines calibrated with laser alignment and test bars.

-

Trusted Worldwide: Used in over 35 countries by professionals and factory operators.

-

Support & Spare Parts: Technical documentation, global parts delivery, and responsive engineering assistance.

Frequently Asked Questions (FAQs)

1. What’s the difference between an engine lathe and a bench lathe?

An engine lathe is a floor-mounted machine designed for heavy-duty tasks, while a bench lathe is compact, portable, and used for lighter machining tasks.

2. What types of workpieces can Alpha lathes process?

Our lathes can process round bars, flanges, hollow pipes, threads, gears, and shafts made of steel, cast iron, brass, aluminum, and more.

3. Are Alpha lathe machines suitable for continuous industrial use?

Yes. Alpha lathes are built for 24/7 industrial use with reinforced structures, durable bearings, and heat-treated components.

4. Do your lathe machines support metric and imperial threading?

Absolutely. The gearbox supports a wide threading range in both metric and inch standards, allowing flexibility for global use.