In gear manufacturing, the accuracy of gear blanks directly impacts the quality, performance, and longevity of the final gear products. Precision lathes dedicated to gear blank machining are critical in establishing exact dimensions, concentricity, and superior surface finishes required before gear cutting or hobbing. These specialized machines provide the rigidity, control, and repeatability essential for the demanding tolerances of modern gear production.

Importance of Gear Blank Precision

Gear blanks must meet strict standards for roundness, flatness, and dimensional uniformity. Any imperfection introduced during blank preparation can compromise gear tooth geometry, lead to imbalance, and accelerate wear during operation. Precision lathes ensure:

-

Consistent Outer Diameter:A uniform OD guarantees proper gear cutting engagement.

-

Precise Bore Finishing:For shaft mounting with minimal runout.

-

Flat Faces:Essential for gear alignment and stability in assemblies.

Key Technical Features of Gear Blank Lathes

-

High-Precision Spindles:Minimize radial runout, ensuring the blank’s axis remains perfectly aligned throughout machining.

-

Dual Turret Options:Allow simultaneous OD and face turning for efficiency and symmetry in machining.

-

Programmable Tailstock:Delivers adjustable support for varying blank sizes, maintaining axial stability.

-

Linear Scales on Axes:Provide real-time feedback for micron-level positioning accuracy.

-

Automatic Tool Offset Compensation:Ensures precision is maintained throughout production, even with tool wear.

Materials Processed

Gear blanks are typically machined from:

-

Alloy Steels:Like 42CrMo4 or 18CrNiMo7-6, providing hardness and wear resistance post-heat treatment.

-

Cast Iron:Often used for large, low-speed gears where vibration damping is key.

-

Aluminum Alloys:For lightweight applications in automotive and aerospace sectors.

Advanced Process Capabilities

-

Facing, OD Turning, and Boring:Precision preparation of all critical dimensions.

-

Chamfering:Prepares the blank for smoother gear cutting initiation and prevents burr formation.

-

Surface Roughness Control:Achieves Ra ≤ 0.8μm on faces and bores for premium gear performance.

Integration with Gear Cutting Processes

Blanks machined on precision lathes proceed directly to hobbing, shaping, or grinding with minimal secondary preparation. The dimensional accuracy achieved minimizes correction cuts during gear cutting, improving efficiency and conserving material.

Quality Control in Gear Blank Machining

-

Roundness and Concentricity Measurement:Using in-process probes or post-machining CMM inspection.

-

Surface Finish Verification:Ensures the smoothness needed for gear tooth formation.

-

Dimensional Analysis:Automated inspection systems confirm tolerances before blanks proceed to gear cutting.

Applications

Precision gear blank lathes are vital in sectors such as:

-

Automotive:For gears in transmissions, differentials, and timing mechanisms.

-

Wind Power:Large-scale gears requiring consistent blank integrity for efficient power generation.

-

Aerospace:Lightweight, high-precision gear systems for actuators and turbines.

-

Industrial Machinery:Gears in heavy-duty equipment that demand flawless engagement and durability.

Conclusion

The precision lathe is indispensable in gear manufacturing, providing the geometric foundation necessary for producing high-quality gears. By ensuring precise diameters, flatness, and alignment, these lathes reduce downstream processing time, enhance gear accuracy, and improve overall production efficiency.

FAQs:

1. Why is concentricity critical in gear blank machining?

Concentricity ensures that the gear teeth, once cut, will engage uniformly during operation. Misalignment from poor concentricity can cause uneven wear, noise, and mechanical failure.

2. What surface finish is required for gear blanks?

A surface roughness of Ra ≤ 0.8μm is typically preferred on gear blank faces and bores to ensure proper seating and gear cutting precision, contributing to the gear’s overall performance.

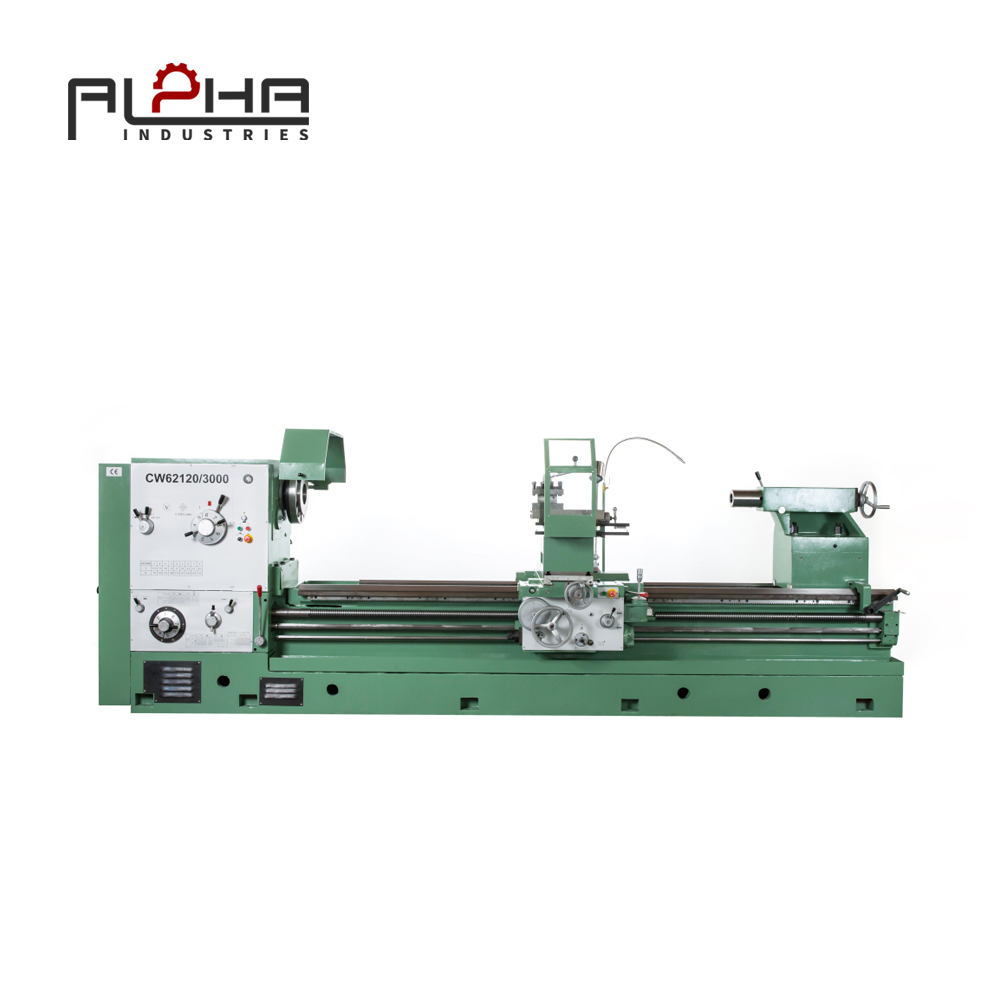

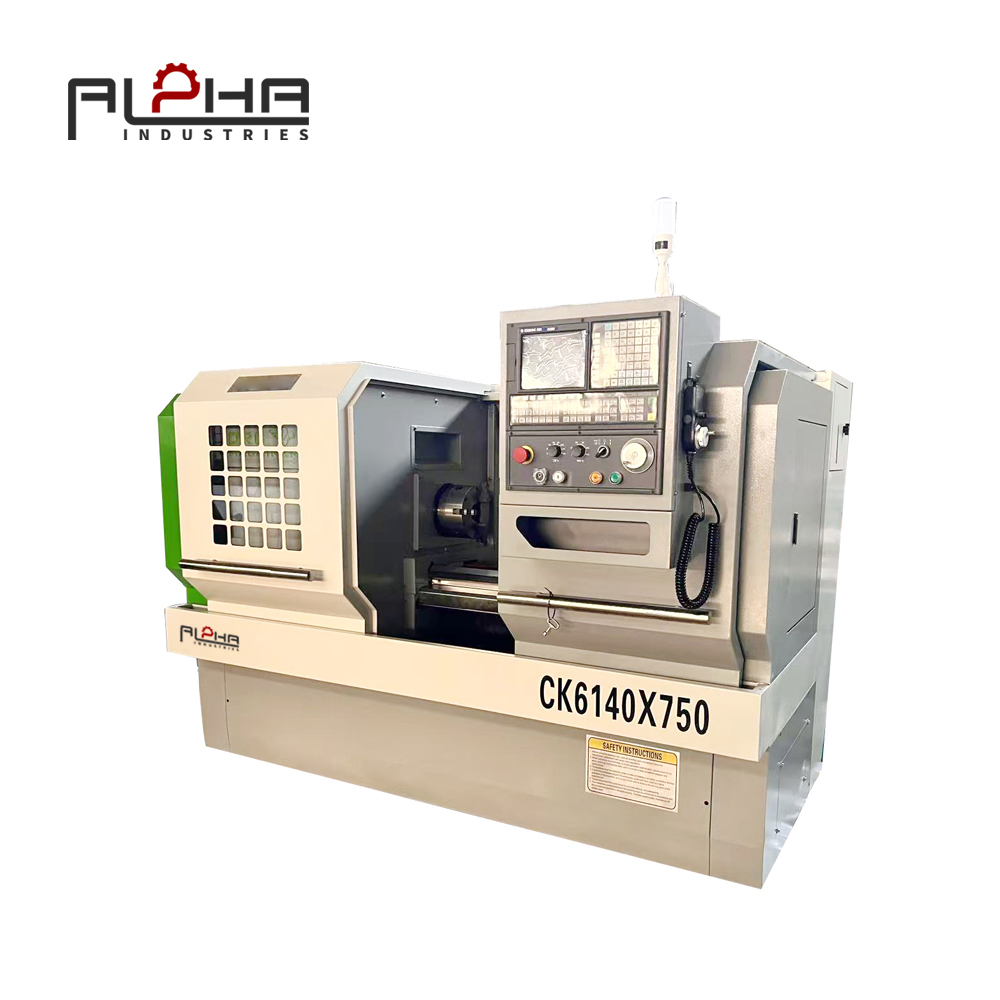

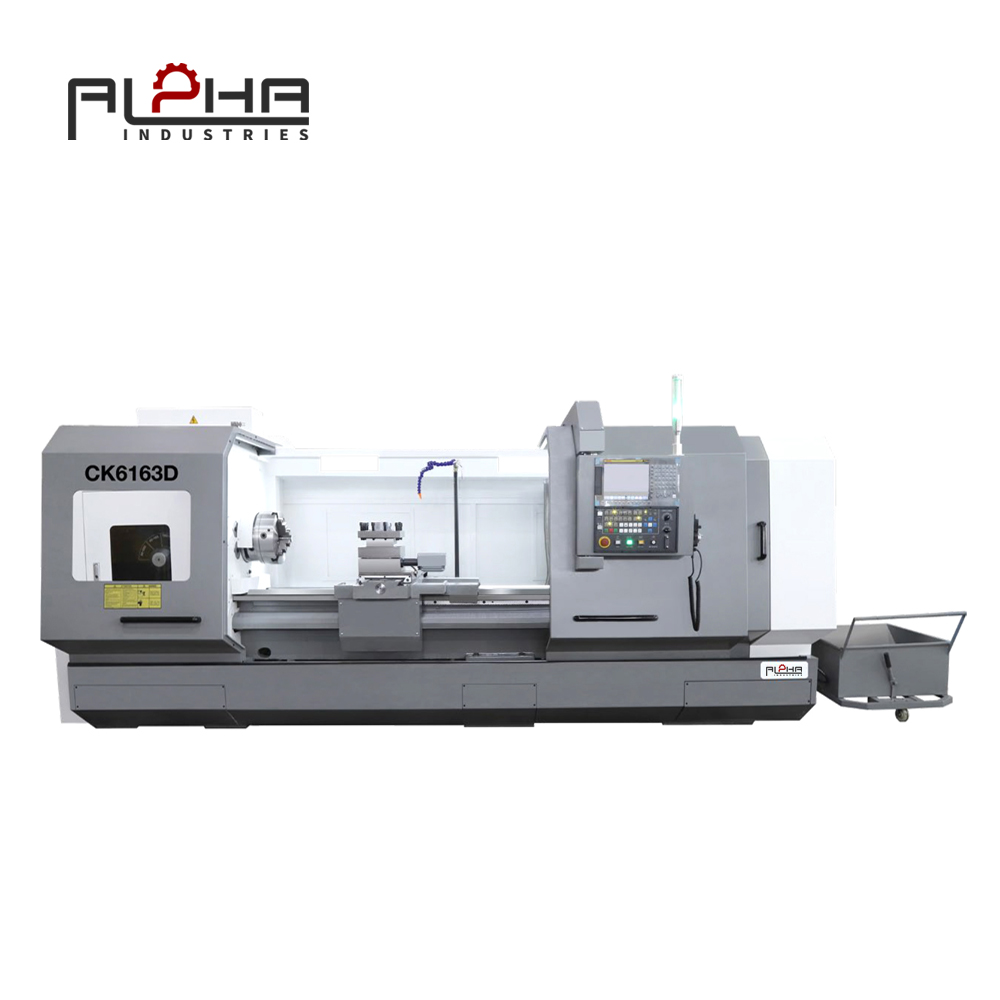

3. Can a precision lathe handle both small and large gear blanks?

Yes, precision lathes come in various capacities, with programmable tailstocks, adjustable chucks, and steady rests to accommodate gear blanks ranging from small automotive gears to large industrial ones.

4. How does blank accuracy affect gear cutting efficiency?

Accurate blanks reduce the need for corrective machining during gear cutting, leading to faster processing, less material waste, and improved gear quality.

5. What tooling is used for machining gear blanks?

Carbide insert tools are commonly used for their durability and ability to maintain edge sharpness during extended machining cycles on steel and cast iron blanks.