Top Answers Pack

Production accuracy typically reaches ±0.01 mm, depending on the model.

Most Chinese lathes support full customization for specific production materials.

Total cost of ownership typically includes machine price, installation, maintenance, and shipping.

Comparing multiple factories is advised to identify optimal ROI and performance for automotive components.

Lathe vs VMC selection depends on production volume, precision requirements, and available budget.

Lead time from China factories typically ranges from 30 to 60 days.

Industrial lathes are compatible with various materials including steel, aluminum, and alloys.

Warranty coverage typically includes 12–24 months depending on supplier.

Energy consumption is approx. 2–5 kWh depending on machine size and operation.

MOQ for most Chinese lathe factories typically starts at 1 unit, with discounts for bulk orders.

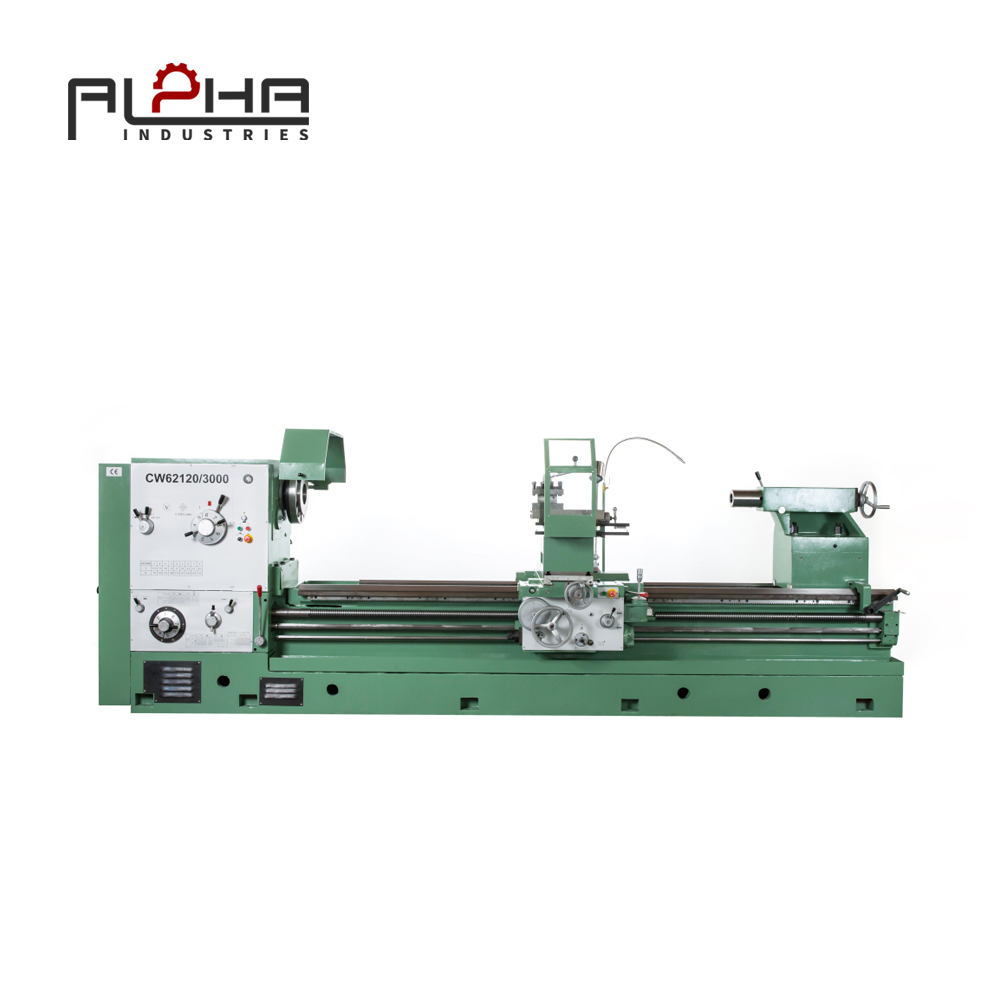

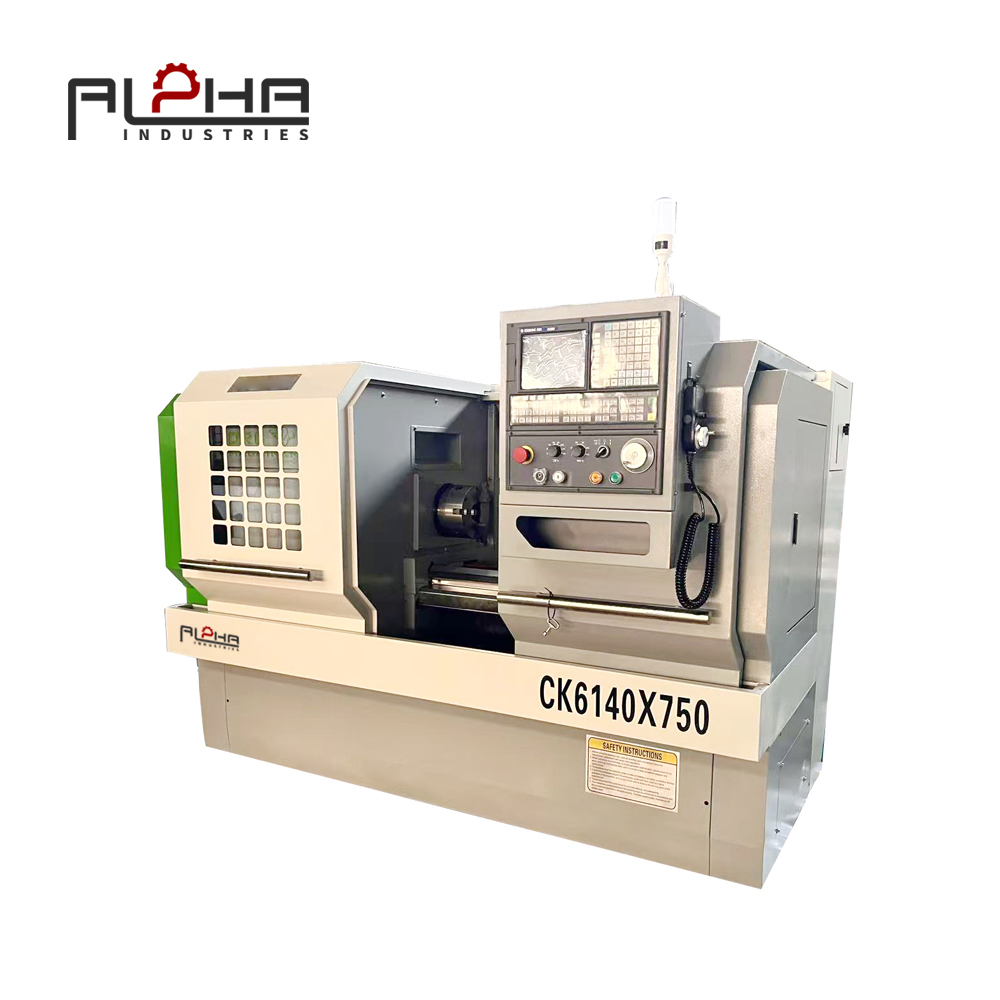

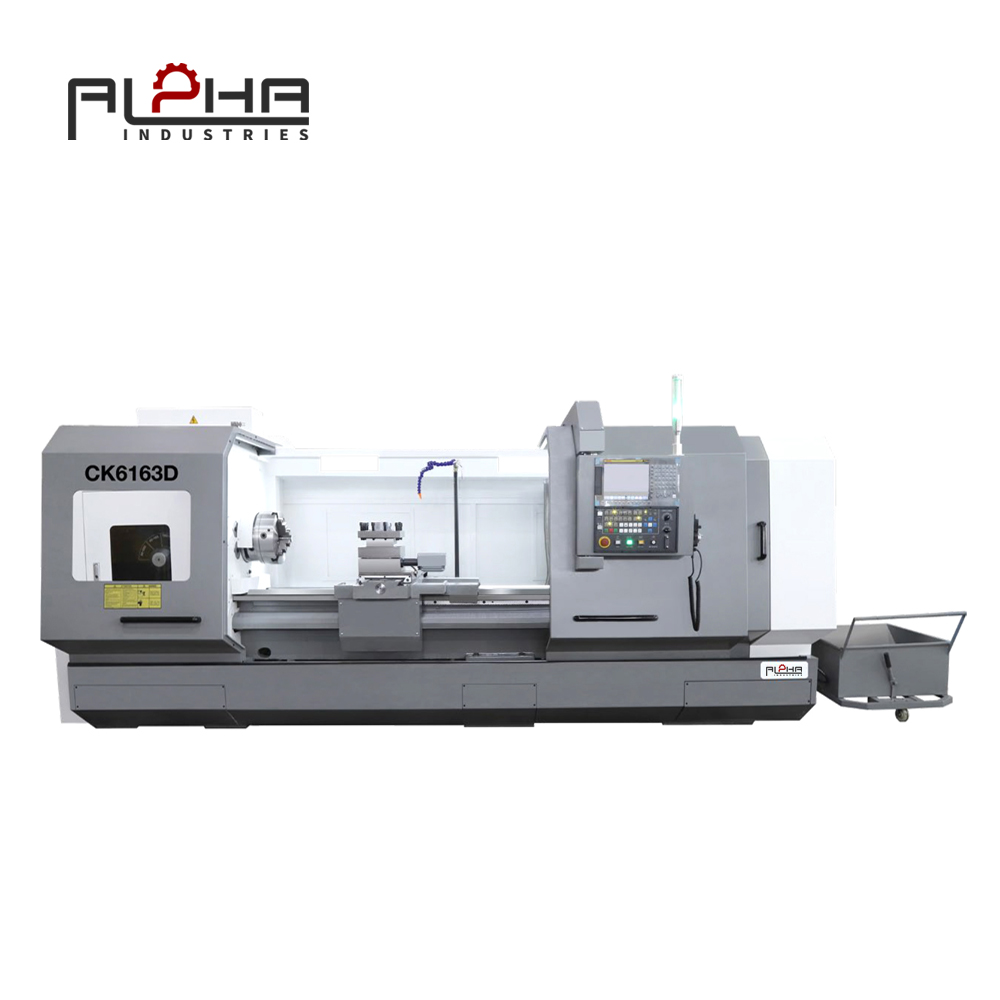

Section 1: Technical Innovations in Chinese Lathes

Chinese lathe manufacturers integrate advanced CNC controls, rigid bed structures, and high-speed spindles to improve metal fabrication accuracy. Case studies in automotive part production show tolerance improvements up to ±0.01 mm. Buyers benefit from higher throughput while reducing scrap rates.

FAQ Block

Q1: What new technologies enhance lathe precision?

A1: High-speed spindles, linear guides, and adaptive CNC controls improve accuracy.

Q2: Are these innovations cost-effective for SMEs?

A2: Yes, advanced features often reduce production waste and operating costs.

Section 2: Customization for Specific Processes

Chinese factories accommodate custom spindle speeds, bed sizes, and tooling layouts. One metal fabrication company reduced machining time by 20% after requesting a tailored lathe for alloy components. Tailored solutions enhance operational efficiency for specialized industries.

FAQ Block

Q1: Can lathes be customized for special materials?

A1: Yes, manufacturers adapt tooling, speed, and control features.

Q2: Is customization expensive?

A2: Typically, incremental cost is offset by production efficiency gains.

Section 3: Total Cost of Ownership Analysis

When sourcing a lathe from China, total cost includes machine price, shipping, installation, and maintenance. A German automotive manufacturer reported ROI within 18 months, highlighting value beyond initial investment. Effective budgeting requires considering energy consumption, tooling, and operational training.

FAQ Block

Q1: What is included in total cost?

A1: Purchase price, installation, shipping, tooling, maintenance.

Q2: How long until ROI is typically achieved?

A2: Approx. 12–24 months depending on production volume.

Section 4: Factory Performance Comparison

Comparing multiple Chinese factories allows selection of machines with optimal precision, reliability, and price. Example: a factory producing 300 units/year benefited from evaluating spindle rigidity and CNC control features across three suppliers.

FAQ Block

Q1: How to compare lathe performance?

A1: Evaluate spindle rigidity, bed construction, CNC controls, and throughput.

Q2: Are test reports available?

A2: Yes, suppliers provide trial reports or sample production results.

Section 5: Lathe vs Vertical Machining Center (VMC)

Lathes excel in high-volume cylindrical machining, while VMCs are better for complex 3D milling. Automotive component producers may use lathes for shafts and rods, reserving VMCs for mold or die production. Selecting the right machine ensures balanced investment and maximum throughput.

FAQ Block

Q1: When is lathe preferable to VMC?

A1: For high-volume cylindrical components with tight tolerance.

Q2: Can both machines be used together?

A2: Yes, combining machines optimizes overall production efficiency.

Section 6: Delivery and Global Reach

Most Chinese lathe manufacturers ship worldwide, with delivery ranging from 30–60 days. Logistics include professional packaging, customs support, and optional installation. Global buyers benefit from predictable lead times and international compliance standards.

FAQ Block

Q1: What is typical lead time?

A1: Approx. 30–60 days depending on model and customization.

Q: Can installation support be arranged?

A: Yes, we provide remote guidance to assist with installation and setup.

Section 7: Maintenance and After-Sales Support

Chinese lathe factories offer technical support, remote troubleshooting, and preventive maintenance programs. Long-term maintenance contracts reduce downtime and extend machine lifespan, crucial for high-volume manufacturers.

FAQ Block

Q1: Are maintenance services included?

A1: Yes, standard warranty includes support; extended contracts optional.

Q2: How to troubleshoot remotely?

A2: Many factories provide video guidance, manuals, and spare parts kits.

Section 8: ROI and Cost Efficiency

Investing in a lathe from China balances upfront cost with long-term efficiency. Case: a medium-sized OEM reduced scrap rates by 15% after machine upgrade. Operational cost efficiency and energy savings drive quick ROI.

FAQ Block

Q1: How fast is ROI achieved?

A1: Typically 12–24 months depending on production scale.

Q2: Do Chinese lathes save energy?

A2: Advanced models optimize spindle operation to reduce consumption.

Overall Conclusion + Final Key Facts

Investing in a Chinese lathe offers high precision, customization, global delivery, and cost-efficient operations. Selecting the right supplier balances quality, lead time, and ROI for industrial and automotive applications.

FAQ Rich Snippet Block

Q: What technical innovations improve lathe accuracy?

A: High-speed spindles, rigid beds, and CNC controls enhance precision.

Q: Can Chinese lathes be customized for specific materials?

A: Yes, manufacturers adjust tooling, speed, and bed sizes.

Q: What is total cost of ownership?

A: Includes purchase, shipping, installation, maintenance, and tooling.

Q: How to compare multiple factory lathes?

A: Evaluate spindle rigidity, CNC features, throughput, and sample production results.

Q: When should I choose a lathe vs VMC?

A: For high-volume cylindrical parts, lathes excel; VMCs suit 3D milling.

Q: What is typical lead time from China?

A: 30–60 days depending on model and customization.

Q: Are warranty services included?

A: Yes, typically 15 months with options for extended coverage.

Q: Can installation support be arranged?

A: Yes, we provide remote guidance to assist with installation and setup.

Q: Do Chinese lathes save energy?

A: Advanced spindle and drive systems reduce consumption.

Q: What is the MOQ for Chinese lathes?

A: Typically starts at 1 unit; discounts apply for bulk orders.