Why Structural Rigidity Defines Milling Machine Performance

In modern metal manufacturing, a milling machine is no longer evaluated solely by spindle speed or control system sophistication. Structural rigidity has become the decisive performance indicator that separates industrial-grade milling machines from general-purpose equipment. For manufacturers pursuing tight tolerances, consistent surface quality, and long-term dimensional repeatability, milling machine rigidity is the foundation that supports every cutting operation.

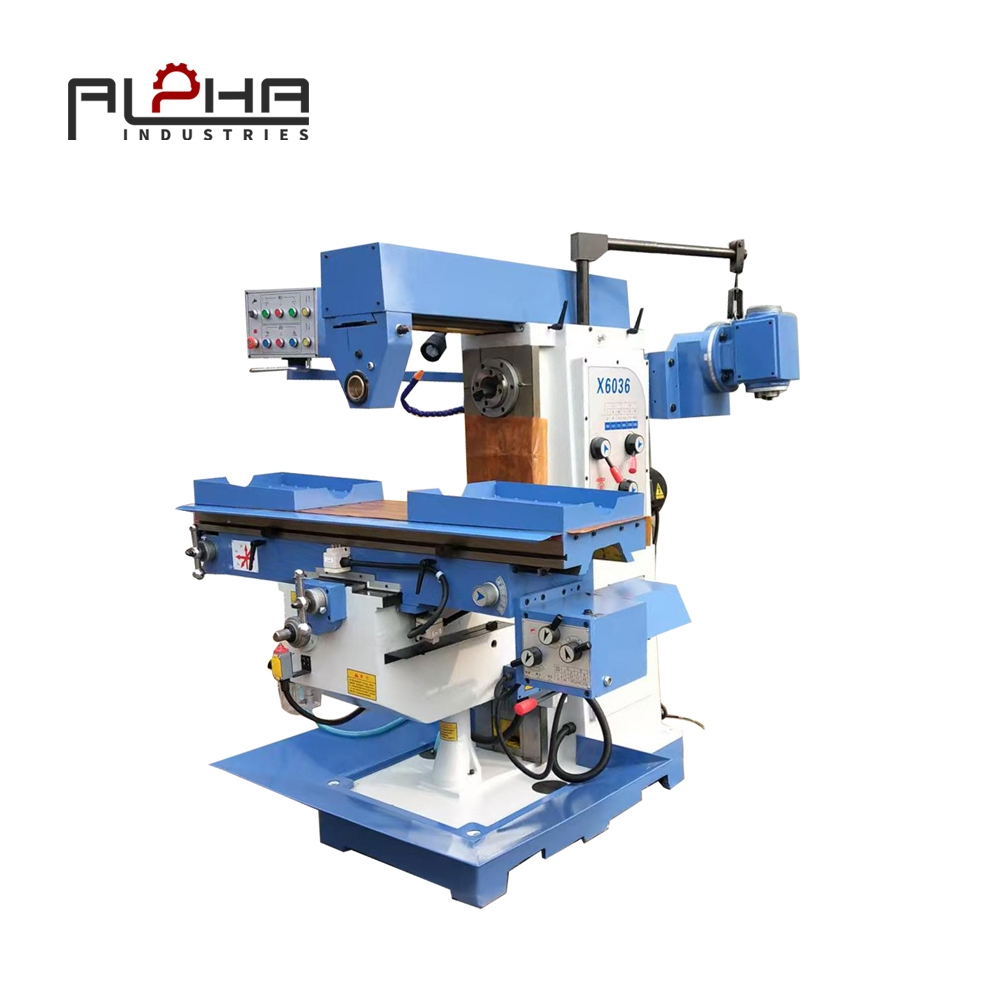

At Alpha, we design milling machines with structural rigidity as a primary engineering principle, ensuring stable material removal, vibration suppression, and predictable machining outcomes under continuous production conditions.

Milling Machine Structural Rigidity Explained

Structural rigidity refers to a milling machine’s ability to resist deformation under cutting forces, spindle torque, and dynamic load variations. During milling operations, radial and axial forces act simultaneously on the spindle, tool holder, workpiece, and machine frame. Any structural weakness directly translates into tool deflection, chatter, or dimensional deviation.

A rigid milling machine structure ensures:

-

Stable tool-workpiece engagement

-

Controlled cutting depth and feed consistency

-

Reduced vibration and resonance

-

Extended tool life

-

Superior surface finish quality

Machine Frame Design: The Backbone of a Milling Machine

High-Mass Cast Iron Construction

The core of a rigid milling machine lies in its machine frame. Alpha milling machines adopt high-density cast iron bases and columns, engineered with deep rib reinforcement. This mass absorbs cutting vibrations and distributes stress evenly throughout the structure, preventing localized deformation.

Thermal aging treatment is applied to all major castings to eliminate internal stress. This process stabilizes the milling machine structure over time, ensuring accuracy retention even after prolonged heavy-duty operation.

Optimized Rib Layout for Load Distribution

Internal rib geometry is strategically designed to align with primary force paths generated during milling. This enhances stiffness without unnecessary material weight, allowing the milling machine to maintain high rigidity while preserving dynamic responsiveness.

Spindle Support and Axis Stability in Milling Machines

Spindle Housing Rigidity

The spindle assembly is a critical load-bearing component. A rigid spindle housing minimizes radial runout and axial displacement during aggressive cutting. Reinforced spindle sleeves and precision bearing arrangements allow the milling machine to handle high cutting forces without performance degradation.

Linear Guideway Integration

High-precision linear guideways, mounted on fully machined reference surfaces, provide stable axis motion. Proper preload selection ensures the milling machine maintains positional accuracy while resisting vibration under variable cutting loads.

How Structural Rigidity Improves Milling Accuracy

A rigid milling machine delivers measurable accuracy advantages:

-

Dimensional Consistency: Reduced elastic deformation ensures part dimensions remain within tolerance across batch production.

-

Surface Finish Control: Stable cutting conditions prevent tool chatter marks and waviness.

-

Geometric Precision: Flatness, perpendicularity, and parallelism are preserved across large workpieces.

-

Repeatability: Identical machining results across multiple cycles and operators.

For precision industries such as mold manufacturing, aerospace components, and mechanical parts processing, these advantages are non-negotiable.

Milling Machine Rigidity and Tool Life

Excessive vibration accelerates tool wear and increases the risk of tool breakage. A structurally rigid milling machine maintains constant chip load and cutting geometry, significantly extending tool life. This reduces tooling costs and machine downtime, directly improving production efficiency.

Application Scenarios Demanding High Rigidity Milling Machines

Rigid milling machines are essential in:

-

Heavy metal removal operations

-

Large plate surface milling

-

Deep cavity machining

-

Precision slot and pocket milling

-

Multi-face machining in a single setup

Alpha milling machines are engineered to support these demanding applications with consistent performance and long-term stability.

Alpha Milling Machine Engineering Philosophy

At Alpha, every milling machine is designed with a rigidity-first mindset. From material selection to structural simulation and final assembly inspection, we prioritize mechanical stability over short-term performance metrics. This approach ensures our milling machines deliver reliable accuracy throughout their service life.

FAQ

What makes a milling machine rigid?

A milling machine achieves rigidity through a heavy-duty cast iron structure, reinforced rib design, precision spindle support, and stable linear guideway systems.

Why is rigidity more important than spindle speed in milling machines?

Without sufficient rigidity, high spindle speed increases vibration and reduces accuracy. Structural rigidity ensures cutting stability regardless of speed.

How does milling machine rigidity affect surface finish?

Higher rigidity minimizes vibration and tool deflection, resulting in smoother, more consistent surface finishes.

Is a heavier milling machine always more rigid?

Not necessarily. Effective rigidity depends on structural design, material quality, and stress distribution, not weight alone.

Conclusion: Structural Rigidity Is the True Value of a Milling Machine

A milling machine’s true performance is determined by its structural rigidity. Precision, stability, efficiency, and long-term accuracy all originate from a mechanically sound foundation. Choosing a rigid milling machine is an investment in consistent quality and production reliability.

Alpha remains committed to delivering milling machines engineered for real-world industrial demands, where precision is sustained, not promised.

👉 Learn more about our solutions or Contact Us to discuss your milling machine requirements.