Why Bending Accuracy Depends on the Press Brake Crowning System

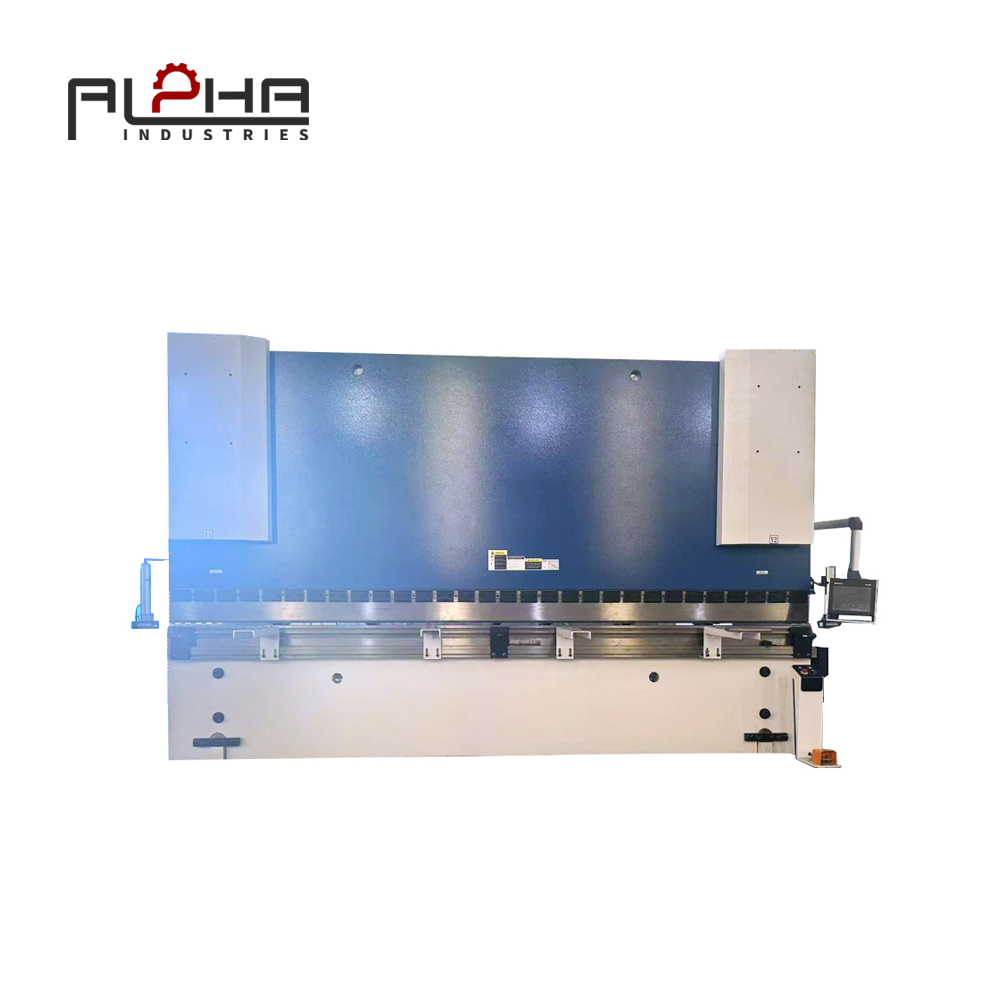

In modern sheet metal fabrication, bending accuracy is the primary performance indicator of a press brake. Even with advanced control systems and high-tonnage capacity, a press brake cannot deliver consistent results without effective compensation for deflection. This is where the press brake crowning system becomes a decisive factor.

During bending, significant force is applied across the press brake ram and worktable. Without compensation, these structural elements naturally deflect, causing angle variation between the center and edges of the workpiece. For manufacturers demanding uniform bend angles, minimal rework, and stable batch production, a well-designed press brake crowning system is essential.

At Alpha, press brake crowning technology is engineered as a core system to ensure reliable bending accuracy under real industrial conditions.

What Is a Press Brake Crowning System?

A press brake crowning system is a mechanical or hydraulic compensation mechanism designed to counteract deflection in the ram and table during bending operations. By applying controlled counter-deformation, the crowning system ensures even force distribution across the full bending length.

The result is consistent bend angles from one end of the sheet to the other, regardless of material thickness, bend length, or applied tonnage.

Why Deflection Occurs in Press Brake Bending

When a press brake applies bending force, the highest load concentration occurs near the center of the machine. This causes the ram and bed to slightly bend downward, while the ends experience less deflection. The longer the bending length and the higher the tonnage, the more pronounced this effect becomes.

Without a crowning system, deflection leads to:

-

Overbending in the center

-

Underbending at the edges

-

Inconsistent angles across the part

-

Increased need for manual adjustment

Types of Press Brake Crowning Systems

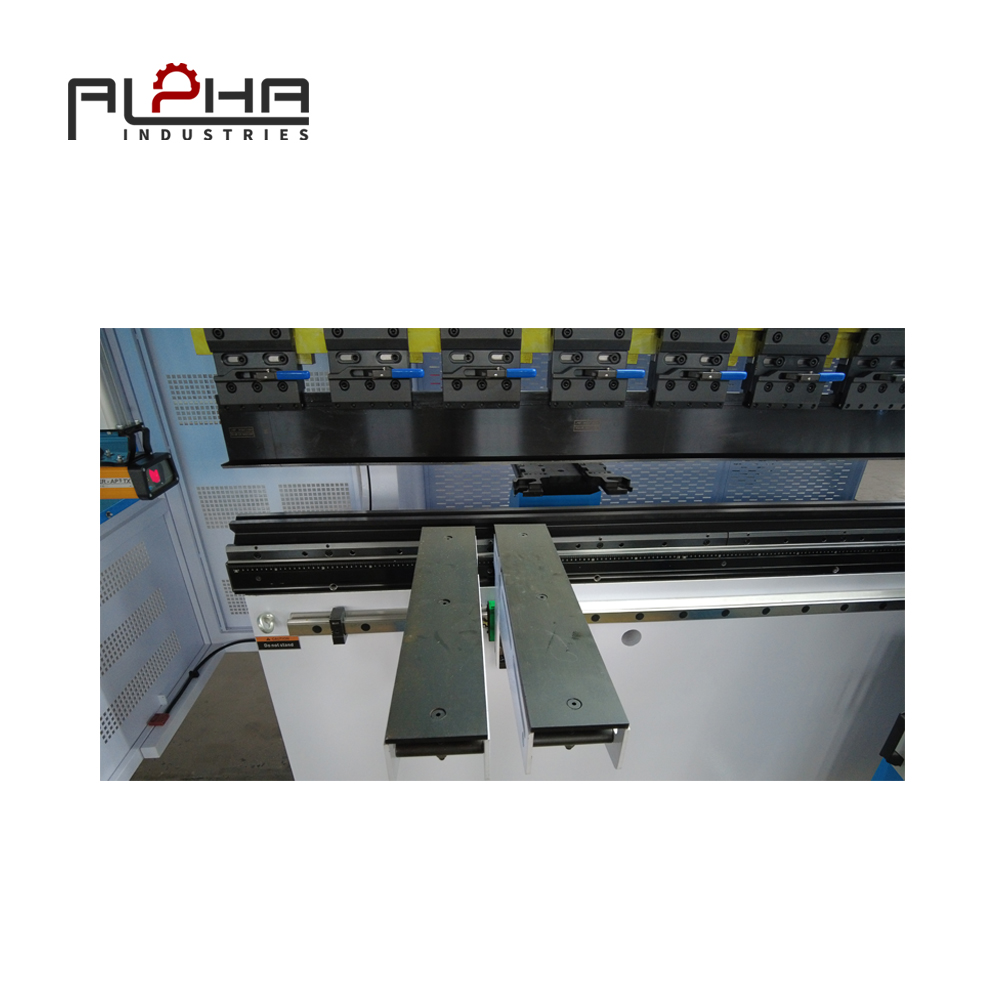

Mechanical Crowning System

Mechanical crowning systems use wedges or adjustable segments integrated into the worktable. Adjustment is typically manual or motor-driven. This solution is robust and cost-effective, suitable for standard bending applications.

Hydraulic Crowning System

Hydraulic crowning systems use synchronized hydraulic cylinders distributed along the worktable. Pressure is automatically adjusted according to bending force, offering real-time compensation and higher precision for complex or variable bending tasks.

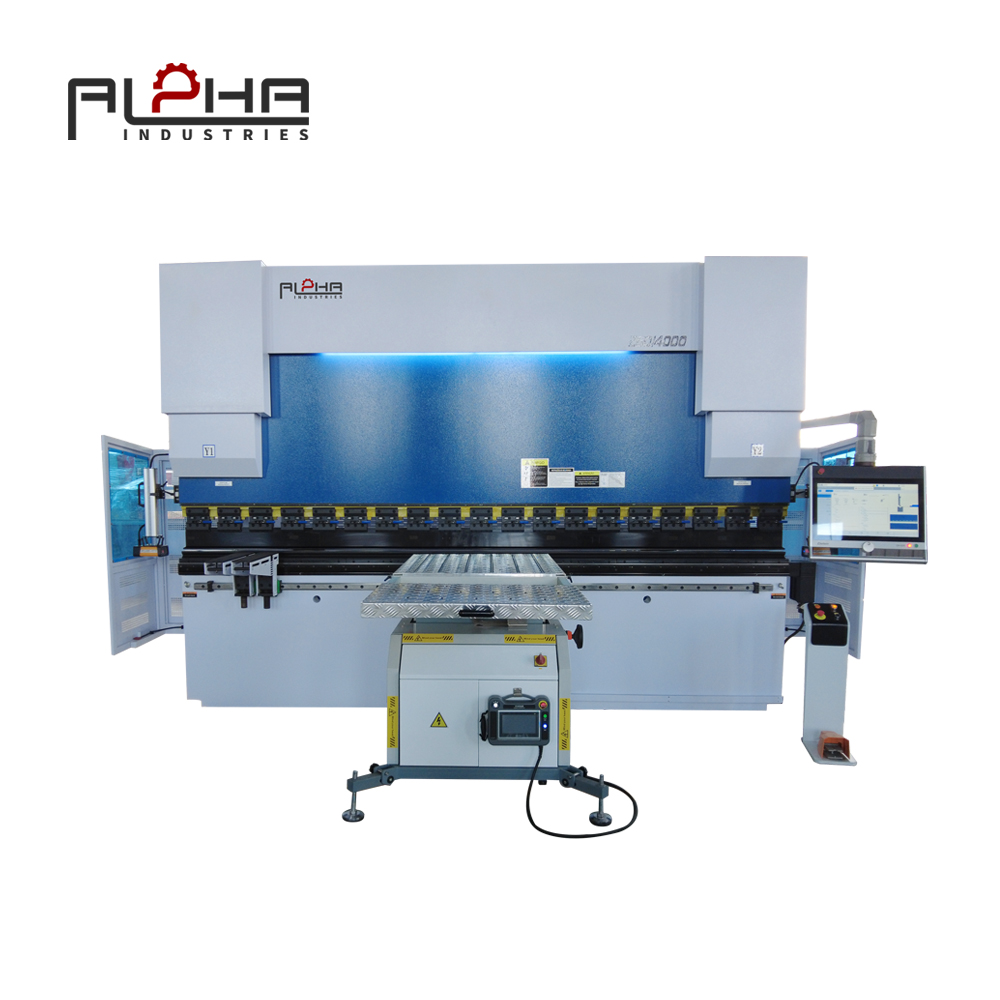

Alpha press brakes are available with optimized hydraulic crowning systems for high-precision sheet metal forming.

How a Crowning System Improves Press Brake Accuracy

An effective press brake crowning system delivers measurable performance improvements:

-

Angle Consistency: Uniform bend angles across the entire sheet width

-

Dimensional Accuracy: Reduced deviation in flange height and bend geometry

-

Repeatability: Stable results across batches and operators

-

Reduced Setup Time: Less trial bending and manual correction

These benefits are critical for industries producing enclosures, panels, frames, and precision metal components.

Crowning System Integration with CNC Press Brakes

In CNC press brakes, the crowning system is integrated with the control system. Bending parameters such as material type, thickness, and bend length are used to calculate the required compensation value automatically.

This integration allows the press brake to adapt instantly to different jobs, improving productivity while maintaining bending accuracy.

Application Scenarios Requiring Advanced Crowning Systems

Press brake crowning systems are essential in:

-

Long-length sheet metal bending

-

High-tolerance precision forming

-

Multi-bend parts requiring consistency

-

Stainless steel and high-strength materials

-

Batch and mass production environments

Alpha press brakes are engineered to support these demanding applications with stable and predictable performance.

Alpha Press Brake Engineering Philosophy

At Alpha, bending accuracy is engineered at the system level. From rigid machine frames and precision ram guidance to advanced crowning compensation, every press brake is designed to deliver consistent results throughout its service life.

Our crowning systems are tested under full-load conditions to ensure real-world reliability, not just theoretical performance.

FAQs

What is the function of a press brake crowning system?

It compensates for ram and table deflection during bending, ensuring uniform bend angles across the workpiece.

Is a crowning system necessary for all press brakes?

For short bends and low tonnage, it may be optional. For long bends and precision work, it is essential.

What is the difference between mechanical and hydraulic crowning?

Mechanical crowning uses fixed or adjustable wedges, while hydraulic crowning provides real-time, automatic compensation.

Does crowning improve repeatability?

Yes. Proper crowning significantly improves angle consistency and batch repeatability.

Conclusion: Crowning System Defines Press Brake Bending Quality

A press brake’s true bending performance depends on its ability to compensate for deflection. The crowning system is the technology that transforms raw bending force into controlled, repeatable accuracy.

By investing in a press brake with an advanced crowning system, manufacturers secure higher quality, lower scrap rates, and more efficient production.

Alpha remains committed to delivering press brakes engineered for precision bending and long-term reliability.

👉 Learn more about our press brake solutions or Contact Us to discuss your bending application requirements.