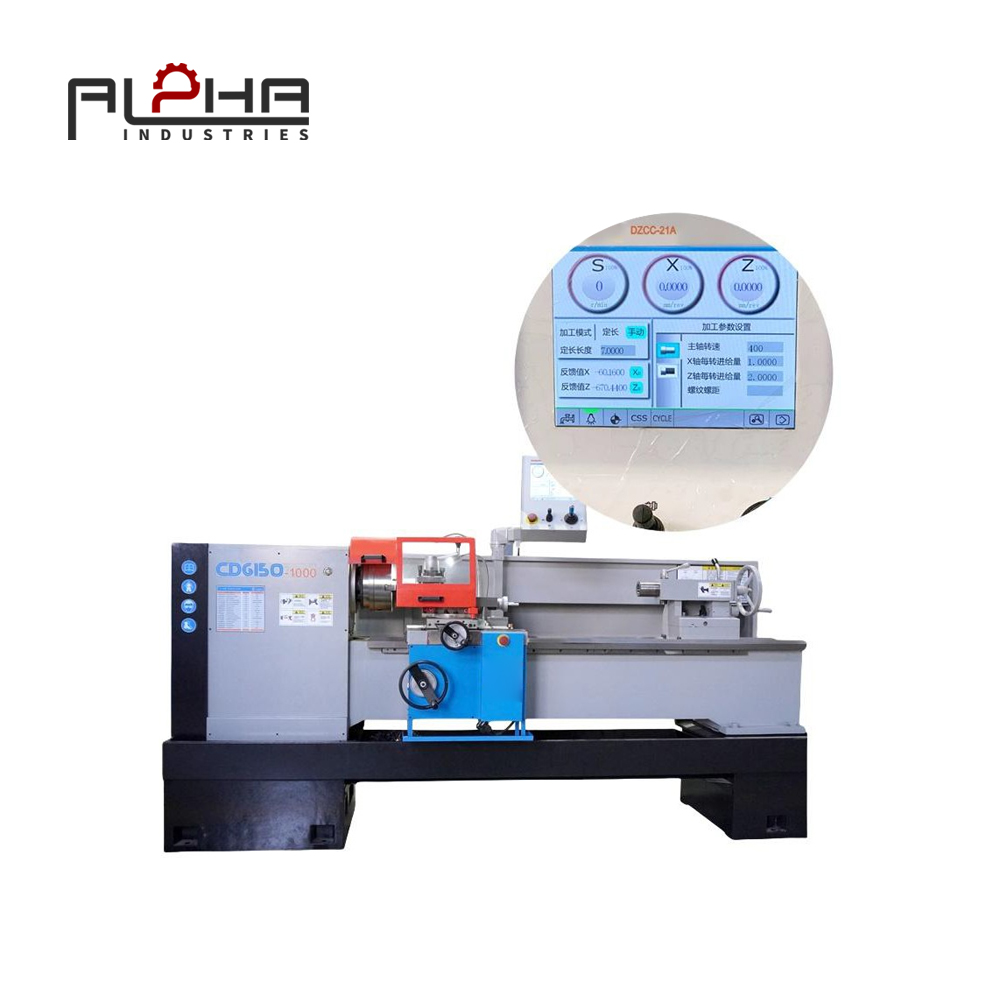

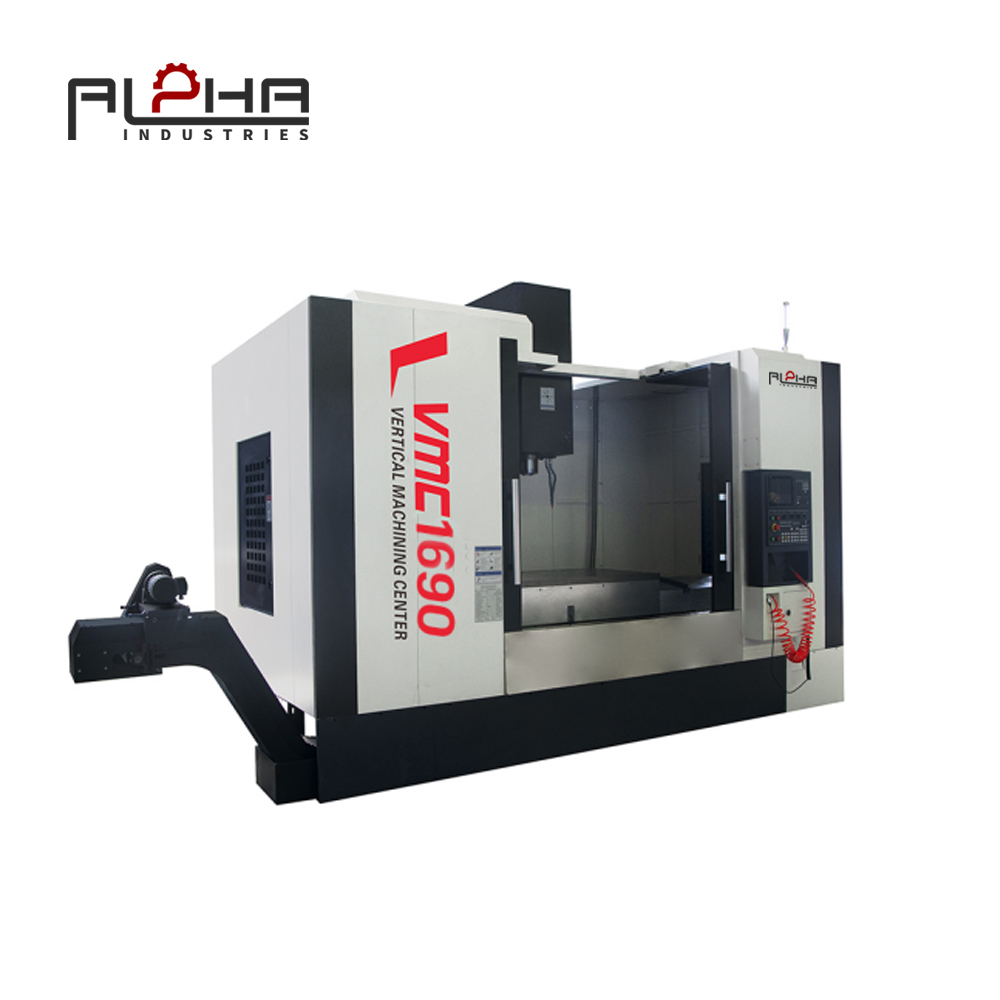

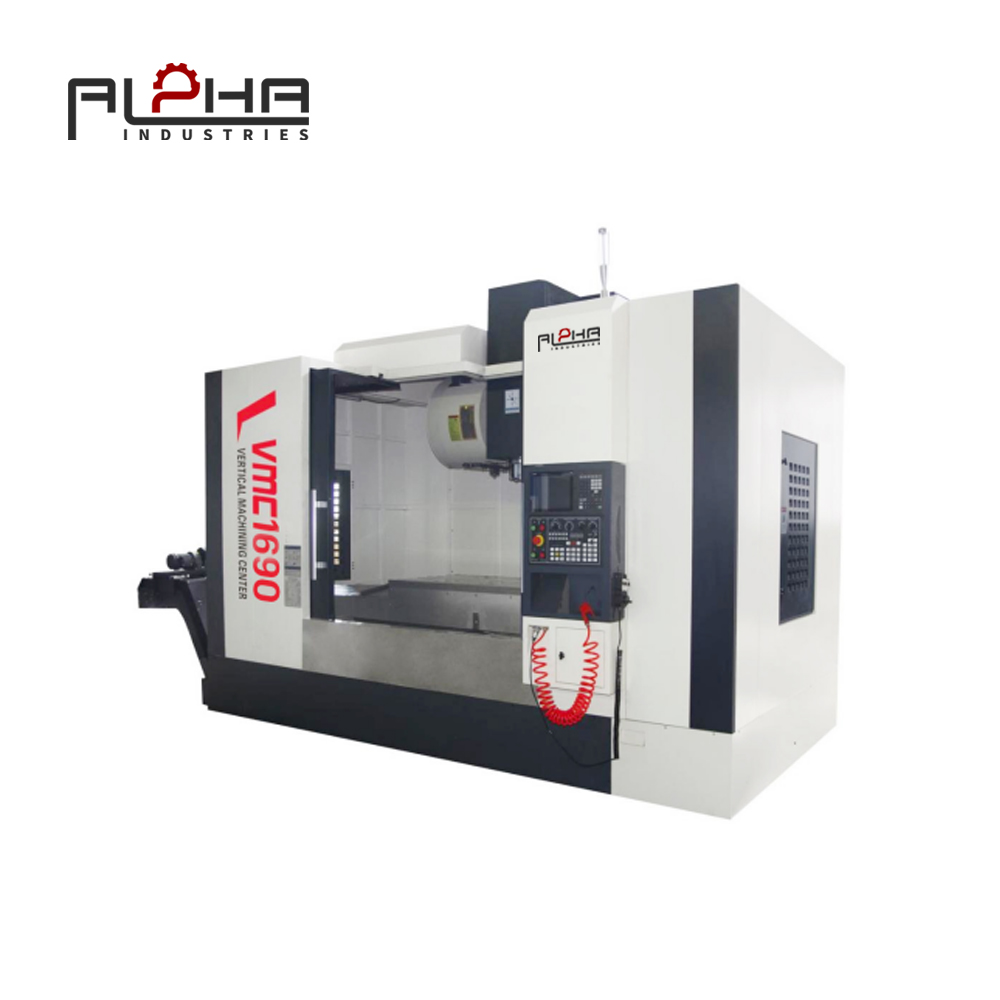

Alpha Lathe Machines – Engineered for Precision & Strength

At Alpha, we design lathe machines that empower metalworking professionals to achieve flawless turning operations with efficiency and consistency. Our lathes combine robust construction, precise movement, and adaptable configurations—making them ideal for everything from job shops to heavy industrial production.

Every lathe from Alpha is built with quality materials, advanced machining standards, and attention to long-term reliability—so your production never misses a beat.

Key Advantages of Alpha Lathe Machines

-

High-Precision Bedways: Induction-hardened and ground guideways reduce friction and ensure long-term alignment.

-

Stable Spindle System: Balanced and dynamically tested spindles allow for high-speed rotation without vibration.

-

Wide Speed Range: Adjustable spindle speeds (manual or gear-driven) support a variety of cutting materials and finishes.

-

Tailstock and Chuck Flexibility: Tailstocks support long shaft work, while multiple chuck options ensure proper clamping.

-

Strong Feed Mechanism: Longitudinal and cross feeds are precisely geared for smooth and accurate tool movement.

Product Series Overview

Manual Engine Lathes – Best for general turning, facing, and threading

Bench Lathes – Compact and portable solutions for light-duty work

Heavy-Duty Lathes – Designed to handle long, thick, and heavy components

Gap Bed Lathes – Offers extra clearance for larger diameter workpieces

Ideal for Various Applications

Our lathes are widely used in:

-

Steel Fabrication Workshops

-

Machinery Manufacturing

-

Shipbuilding and Marine Repair

-

Mining and Oil Industries

-

Maintenance and Repair Operations (MRO)

-

Technical Schools and Training Centers

What Makes Alpha Your Ideal Lathe Partner?

-

Durable Construction: Every machine is rigorously tested for bed flatness, spindle alignment, and headstock balance.

-

Global Service Coverage: Full documentation, spare parts availability, and export-ready packaging.

-

Custom-Built Capabilities: From tool post types to digital readouts (DRO), we match your workflow needs.

Frequently Asked Questions (FAQ)

1. What operations can I perform with an Alpha lathe?

With Alpha lathes, users can perform turning, tapering, threading, grooving, drilling, boring, and parting operations on a wide range of materials.

2. How does a metal lathe differ from a wood lathe?

Metal lathes are stronger and more precise, designed to cut tough materials like steel or aluminum using powered feed and tool rigidity. Wood lathes are simpler, using hand-held tools.

3. How can I maintain my lathe machine?

Regular lubrication, slideway cleaning, checking spindle alignment, and timely replacement of worn components are essential to maintain optimal performance.

4. Can I use DRO systems on Alpha lathes?

Yes, many Alpha lathe models support optional DRO systems for improved accuracy and easy dimension control.

5. Does Alpha provide installation and training?

Yes. We offer online video guides, manuals, and remote technical support for installation and operation. On-site training can also be arranged upon request.