Press Brake Deflection Compensation: The Foundation of Precision Bending

In high-tonnage sheet metal bending, machine deflection is one of the primary causes of angle inconsistency. When a press brake applies force to a workpiece, the ram and table naturally deform under load. Without effective deflection compensation, this deformation results in uneven bending angles across the working length.

For manufacturers demanding tight tolerances and repeatable quality, press brake deflection compensation is not optional. It is a fundamental technology that directly determines bending accuracy, product consistency, and production efficiency. Alpha designs press brake systems with advanced deflection compensation solutions to meet professional industrial requirements.

Why Deflection Occurs in Press Brake Operations

Deflection occurs because bending force is not uniformly distributed along the press brake bed. The center of the machine typically experiences higher load concentration, causing downward deformation of the ram and upward deformation of the table.

If deflection is not corrected, the bending angle in the center of the sheet will differ from the edges. This issue becomes more severe when bending:

-

Long workpieces

-

Thick plates

-

High-strength materials

-

Parts requiring tight angular tolerances

Effective press brake deflection compensation neutralizes these structural deformations, ensuring uniform bending results.

Types of Press Brake Deflection Compensation Systems

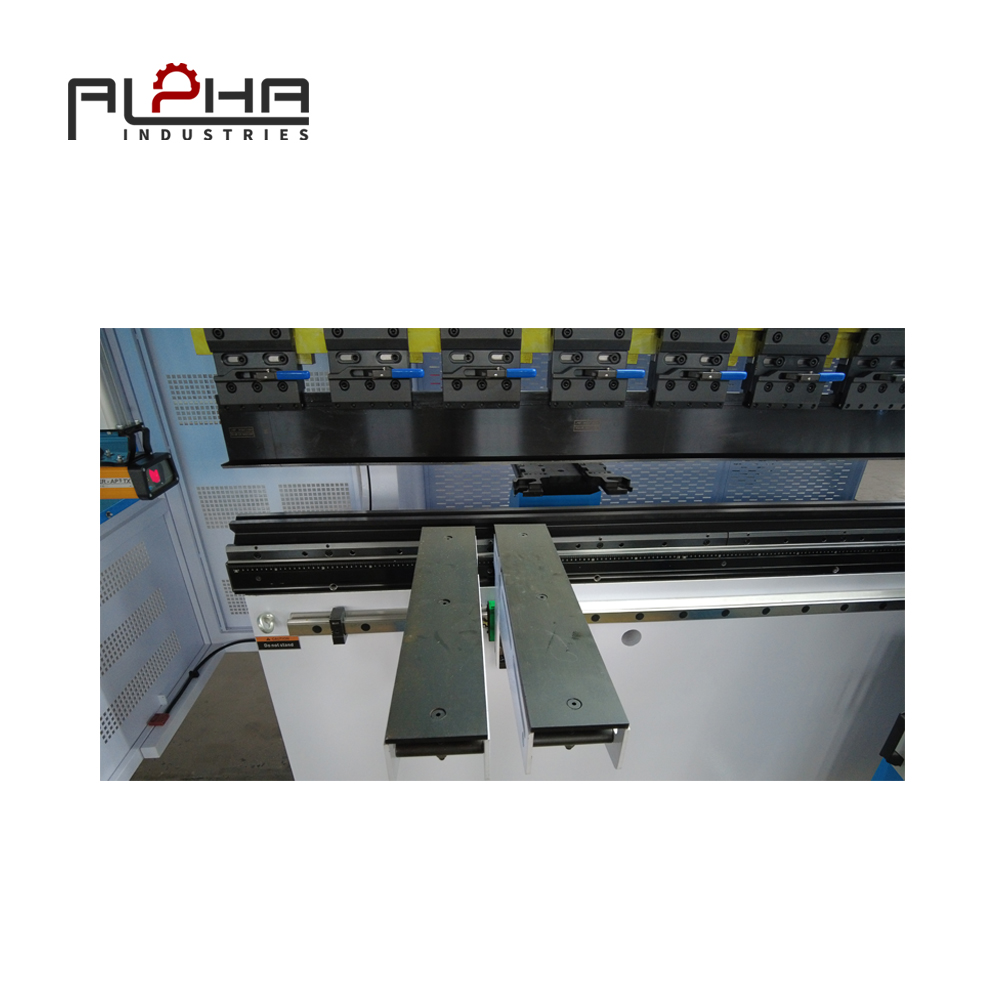

Mechanical Crowning Systems

Mechanical crowning systems use wedge blocks or adjustable shims installed in the press brake table. By manually adjusting the crowning amount, operators can compensate for predictable deflection patterns.

While reliable, mechanical systems require experience and manual setup, making them less suitable for frequent material changes or flexible production.

Hydraulic Deflection Compensation

Hydraulic compensation systems use multiple hydraulic cylinders installed beneath the table. These cylinders apply upward force dynamically during bending, counteracting real-time deflection.

Hydraulic deflection compensation offers:

-

Automatic adjustment based on bending force

-

High accuracy across the full working length

-

Reduced setup time

-

Improved repeatability for batch production

Alpha press brakes commonly adopt hydraulic compensation technology to support demanding industrial applications.

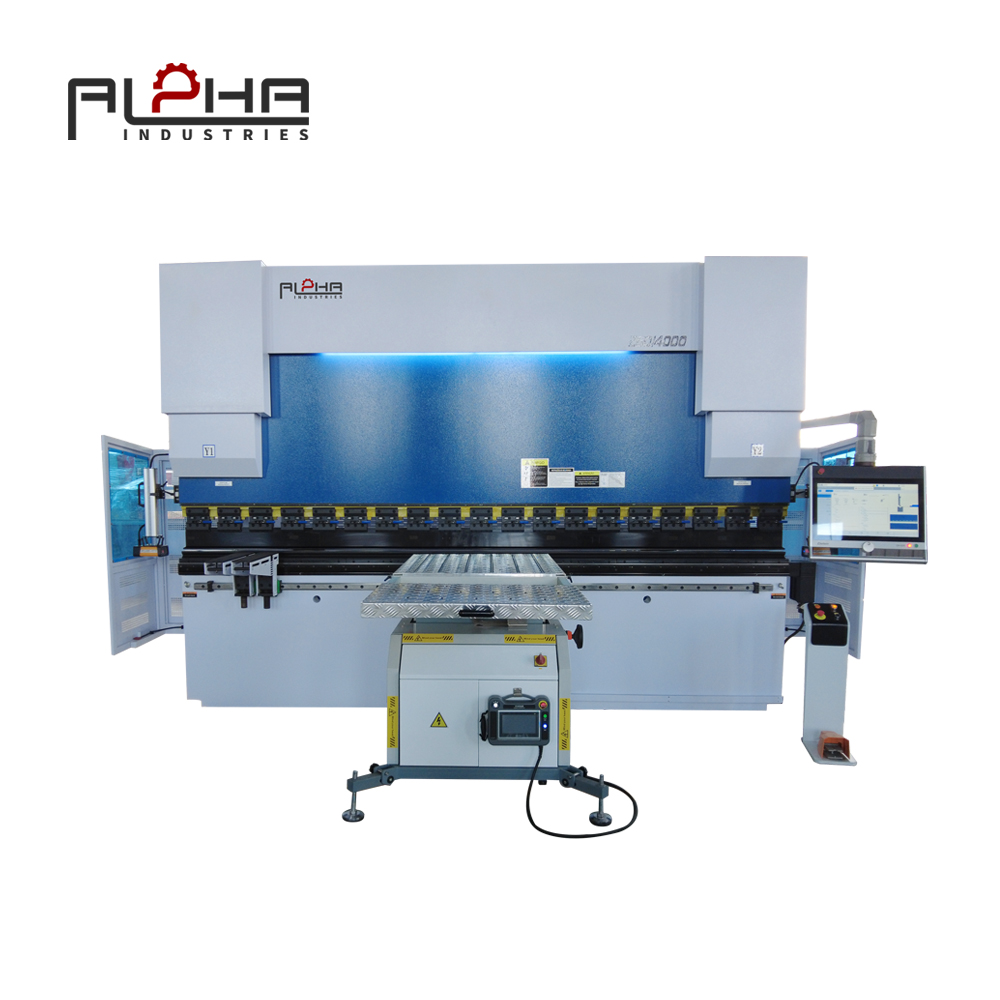

Control System Integration and Compensation Accuracy

Modern press brake control systems play a critical role in deflection compensation. The controller calculates required compensation values based on:

-

Material thickness and tensile strength

-

Bending length

-

Target bending angle

-

Applied tonnage

Integrated control systems allow compensation to be adjusted automatically for each bending program, ensuring first-piece accuracy and minimizing trial bending.

Benefits of Advanced Deflection Compensation in Press Brakes

A well-designed press brake deflection compensation system delivers measurable production advantages:

-

Consistent bending angles across the entire workpiece

-

Reduced scrap and rework rates

-

Improved dimensional accuracy in downstream assembly

-

Higher production efficiency

-

Lower dependency on operator experience

For manufacturers working with precision enclosures, structural components, and high-value sheet metal parts, these benefits directly translate into cost savings and quality improvement.

FAQ

What is deflection compensation in a press brake?

Deflection compensation is a technology that offsets ram and table deformation during bending to maintain uniform angles along the entire bending length.

Is hydraulic deflection compensation better than mechanical crowning?

Hydraulic systems provide automatic, real-time adjustment and are more suitable for high-precision and flexible production environments.

Does deflection compensation affect bending speed?

No. Properly integrated compensation systems operate synchronously with the bending process and do not reduce production speed.

Is deflection compensation necessary for short bends?

While less critical for short parts, compensation becomes essential for long, thick, or high-precision workpieces.

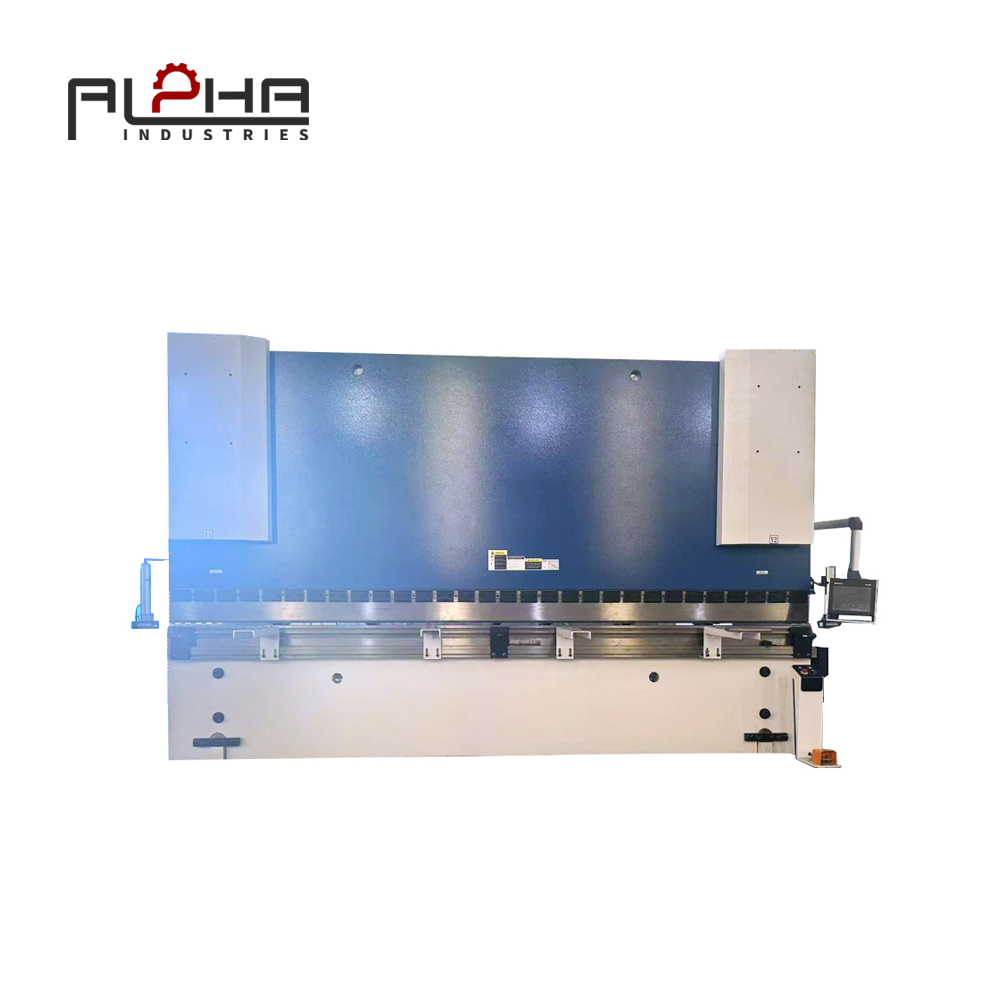

Why Choose Alpha Press Brake Technology

Alpha specializes in press brake solutions engineered with robust structures, intelligent control systems, and high-performance deflection compensation technology. Our machines are designed to deliver stable bending accuracy under continuous industrial operation.

Whether your production involves custom fabrication or high-volume manufacturing, Alpha press brakes provide the precision and reliability required for professional metal forming.

To explore Alpha press brake solutions or discuss your application requirements, please visit our Contact Us page.