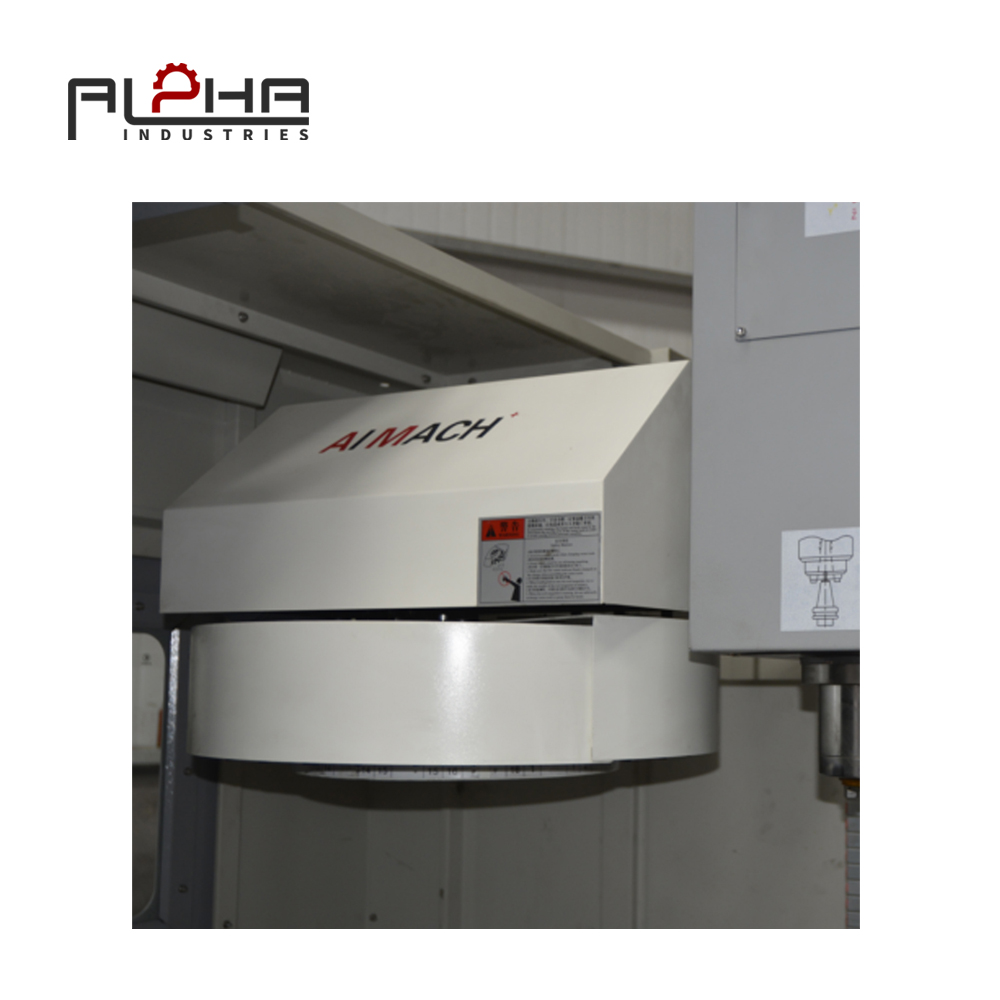

A VMC (Vertical Machining Center) is a high-performance machine designed for precision metalworking. It integrates advanced milling, drilling, and tapping capabilities into a single automated system. With its vertical spindle orientation, the VMC offers superior rigidity and stability, ensuring high accuracy for complex metal components. Industries such as aerospace, automotive, and die manufacturing rely heavily on VMCs for precision and productivity.

For complementary metalworking solutions, check our CNC Lathe Machines and Surface Grinder Machines.

Key Features of a VMC Vertical Machining Center

-

High Precision Spindle: Equipped with a precision spindle, VMCs maintain minimal runout, delivering accurate cuts for high-tolerance components.

-

Rigid Structure: Built from stress-relieved cast iron, the frame reduces vibration and deformation during heavy-duty operations.

-

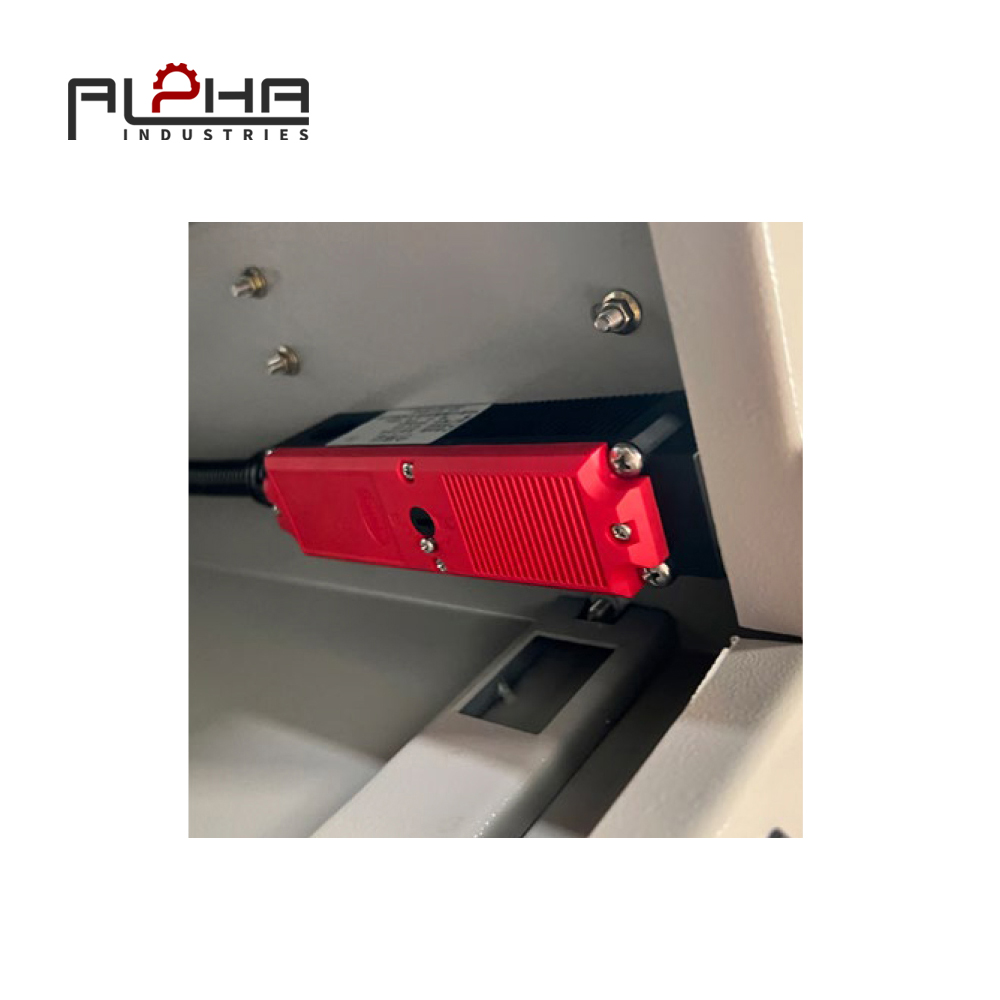

Automatic Tool Changer (ATC): Reduces downtime by allowing automatic switching between multiple tools during machining cycles.

-

User-Friendly CNC Control: Modern VMCs integrate advanced CNC systems that simplify programming, improve operational efficiency, and reduce operator errors. Learn more about our CNC Press Brakes.

-

Large Work Envelope: Capable of handling both small and large workpieces, accommodating diverse industrial requirements.

-

High-Speed Machining: Optimized for high-speed milling and drilling, improving productivity without compromising precision.

Advantages of Using a VMC Vertical Machining Center

-

Enhanced Accuracy: Vertical spindle design reduces deflection, enabling high-precision cuts.

-

Improved Efficiency: Automated tool changes and optimized CNC programming minimize idle time.

-

Versatility: Suitable for various materials including steel, aluminum, and titanium.

-

Reduced Labor Costs: Automation reduces reliance on manual operations, improving workplace safety.

-

Consistency in Production: Ideal for both prototype development and mass production, maintaining repeatable accuracy.

For additional precision operations, explore our High Precision Surface Grinder.

Applications of VMC Vertical Machining Centers

VMCs are widely used across industries for complex metal fabrication:

-

Aerospace: Precision components such as turbine blades and structural parts.

-

Automotive: Engine blocks, transmission housings, and suspension components.

-

Electronics: Enclosures, connectors, and heat sinks.

-

Mold and Die Manufacturing: High-precision molds, dies, and tooling components.

-

General Metal Fabrication: Customized parts requiring high tolerance and finish quality.

FAQ: VMC Vertical Machining Center

Q1: What is a VMC Vertical Machining Center?

A: A VMC is a machine that performs precision milling, drilling, and tapping using a vertically oriented spindle, ideal for high-accuracy metalworking applications.

Q2: How does a VMC improve machining accuracy?

A: The vertical spindle orientation reduces deflection, combined with a rigid frame and precision spindle to maintain consistent tolerance across complex operations.

Q3: Which industries use VMCs the most?

A: Aerospace, automotive, electronics, mold making, and general metal fabrication industries rely heavily on VMCs for precision and efficiency.

Q4: Can VMCs handle large workpieces?

A: Yes, VMCs are designed with a wide work envelope, allowing for machining of both small and large components efficiently.

Q5: What is the difference between a VMC and a conventional milling machine?

A: Unlike conventional mills, VMCs integrate CNC control, automatic tool changers, and high-speed precision capabilities, ensuring higher accuracy, repeatability, and automation. For more comparisons, see Vertical vs Horizontal Machining Centers.

The VMC Vertical Machining Center by ALPHA is a cornerstone of modern metalworking, providing unmatched precision, reliability, and efficiency. For manufacturers aiming to improve productivity while maintaining high tolerance standards, VMCs offer a versatile solution suitable for a wide range of industries. Investing in a VMC ensures consistent quality, faster production cycles, and adaptability for complex machining tasks.