Challenges in Precision Metal Bending

In metal fabrication, precision and efficiency are critical to producing high-quality components. Businesses face numerous challenges, such as achieving consistent bends on a variety of materials, reducing operator errors, and minimizing setup times. Traditional manual bending methods often fall short, leading to costly inefficiencies and errors that impact overall productivity.

For industries dealing with high-volume or intricate bending operations, these limitations become even more prominent. This is especially true when bending metals like steel or aluminum, where accuracy and repeatability are crucial. The demand for an advanced yet user-friendly solution has never been greater.

Meet the Solution: Alpha PBG 135x3100 CNC Press Brake

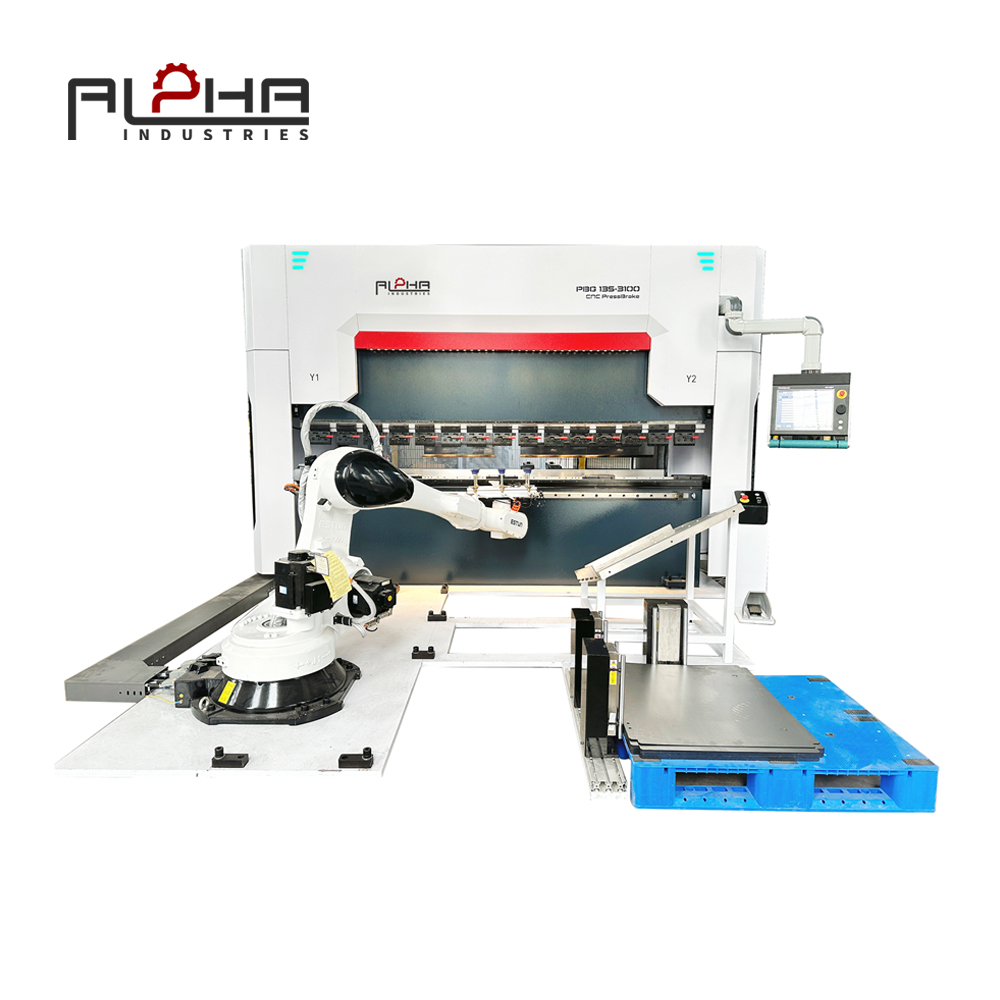

Alpha has addressed these challenges with its state-of-the-art **PBG 135x3100 CNC Press Brake**. This precision CNC bending machine represents a new benchmark in metalworking technology, blending advanced features with automated efficiency to transform the industry.

At its core, this **automatic press brake** combines a robust 135-ton bending force and a working length of up to 3100 mm, making it ideal for industrial-grade applications. Whether dealing with standard or complex bends, the machine delivers unparalleled consistency. With its innovative CNC system, errors are minimized, and production lines are optimized for maximum output. It’s a game-changer for those seeking to take their metal fabrication processes to the next level.

Advanced Features for Maximum Productivity

One of the standout features of the PBG 135x3100 is its **intelligent CNC control system**, designed for seamless automation and customization. The intuitive control interface streamlines programming and drastically reduces setup time. Whether you're a seasoned operator or new to CNC machinery, the user-friendly touchscreen makes complex operations straightforward and efficient.

Equipped with a **multi-axis back gauge system** and modular tooling, this machine adapts effortlessly to diverse bending needs. From intricate parts to large-scale components, the versatility of this industrial press brake ensures it can handle various manufacturing demands with ease. Its ergonomic open-back structure further enhances usability and efficiency, offering a superior work experience for operators.

Reliability and Innovation Combined

Built to endure rigorous industrial conditions, the **PBG 135x3100 CNC Press Brake** underscores Alpha Industries’ dedication to reliability and innovation. The machine incorporates high-quality components, including durable hydraulic systems and advanced electrical circuitry, to ensure long-term performance with minimal downtime. Safety is also paramount, as demonstrated by its laser-guided safety system, combining operator protection with full operational efficiency.

Beyond functionality, the machine's distinctive blue-and-white aesthetics reflect its cutting-edge engineering and modern design. This isn't just a piece of equipment—it’s a symbol of commitment to excellence and sustainability in the sheet metal fabrication industry.

Why Choose Alpha ?

As a leading provider of CNC machinery, **Nanjing Alpha CNC Co., Ltd** goes beyond selling equipment; they deliver complete solutions. With a highly skilled R&D team, the company ensures world-class design and manufacturing capabilities. Customers don’t just get a machine—they gain a partner dedicated to enhancing their operations through safe, cost-effective solutions and responsive support.

The Alpha **PBG 135x3100 CNC Press Brake** is more than just a precision press brake. It’s a testament to how advanced technology and innovative design can overcome the challenges of modern metal bending. Businesses looking for precision, productivity, and durability will find their perfect ally in this machine.