Press Brake Bending Accuracy Control in Modern Metal Forming

In sheet metal fabrication, bending accuracy is the decisive factor that separates standard forming equipment from truly high-performance press brake solutions.

For manufacturers producing enclosures, frames, cabinets, brackets, and structural components, even a ±0.1 mm deviation can result in assembly failure, poor aesthetics, or increased rework costs.

At ALPHA, press brake design focuses on system-level bending accuracy control, ensuring consistent angle repeatability and dimensional stability across long production runs.

Why Bending Accuracy Is the Core Performance Indicator of a Press Brake

Bending accuracy directly affects:

-

Final part dimensions

-

Angle consistency across batch production

-

Material springback compensation

-

Assembly fit and surface appearance

-

Overall production efficiency

Unlike cutting operations, bending accuracy is influenced by multiple interacting mechanical variables, not just control commands.

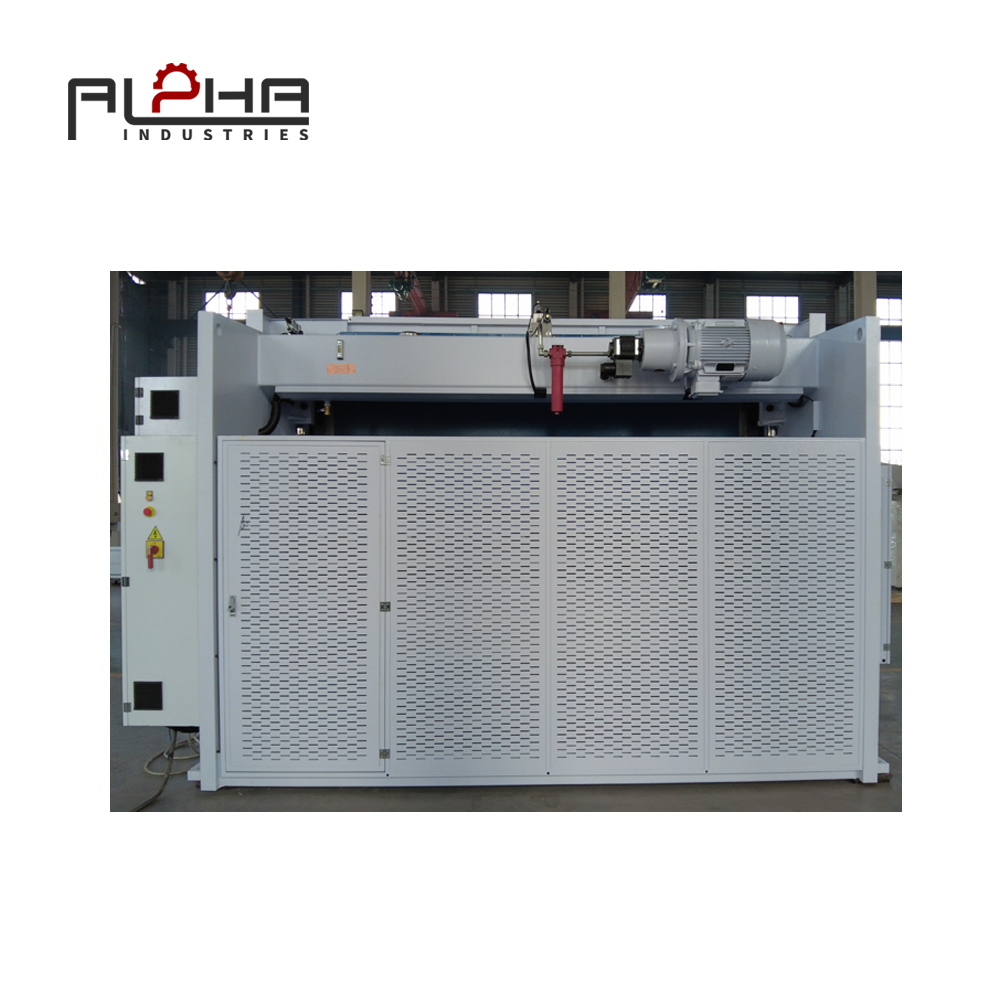

Structural Rigidity — The Foundation of Accurate Bending

High-Rigidity Frame Design

A press brake frame must resist deflection under full tonnage load.

ALPHA press brakes utilize:

-

Heavy-duty welded steel frames

-

Stress-relieved structures after welding

-

Optimized throat depth and side wall thickness

This rigidity minimizes elastic deformation during bending, maintaining uniform force distribution along the bending length.

Crowning System — Controlling Deflection in Long Bends

Why Crowning Is Essential

During long-sheet bending, the ram and table naturally deflect under pressure. Without compensation, this causes:

-

Over-bending at both ends

-

Under-bending in the center

Mechanical and Hydraulic Crowning Solutions

ALPHA integrates precision crowning systems to dynamically compensate deflection:

-

Mechanical crowning with wedge blocks

-

Hydraulic crowning for real-time adjustment

-

Uniform angle distribution across full working length

This ensures consistent bend angles from edge to edge, even on thick or high-strength materials.

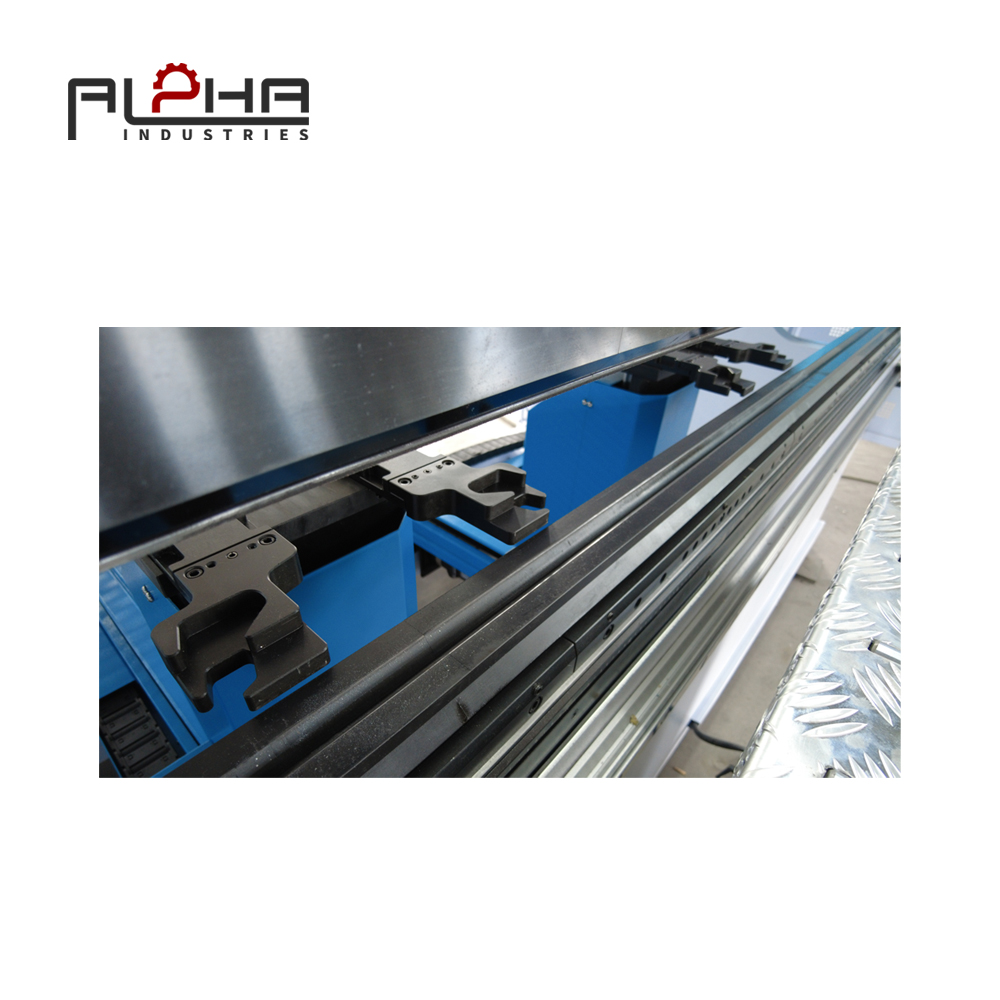

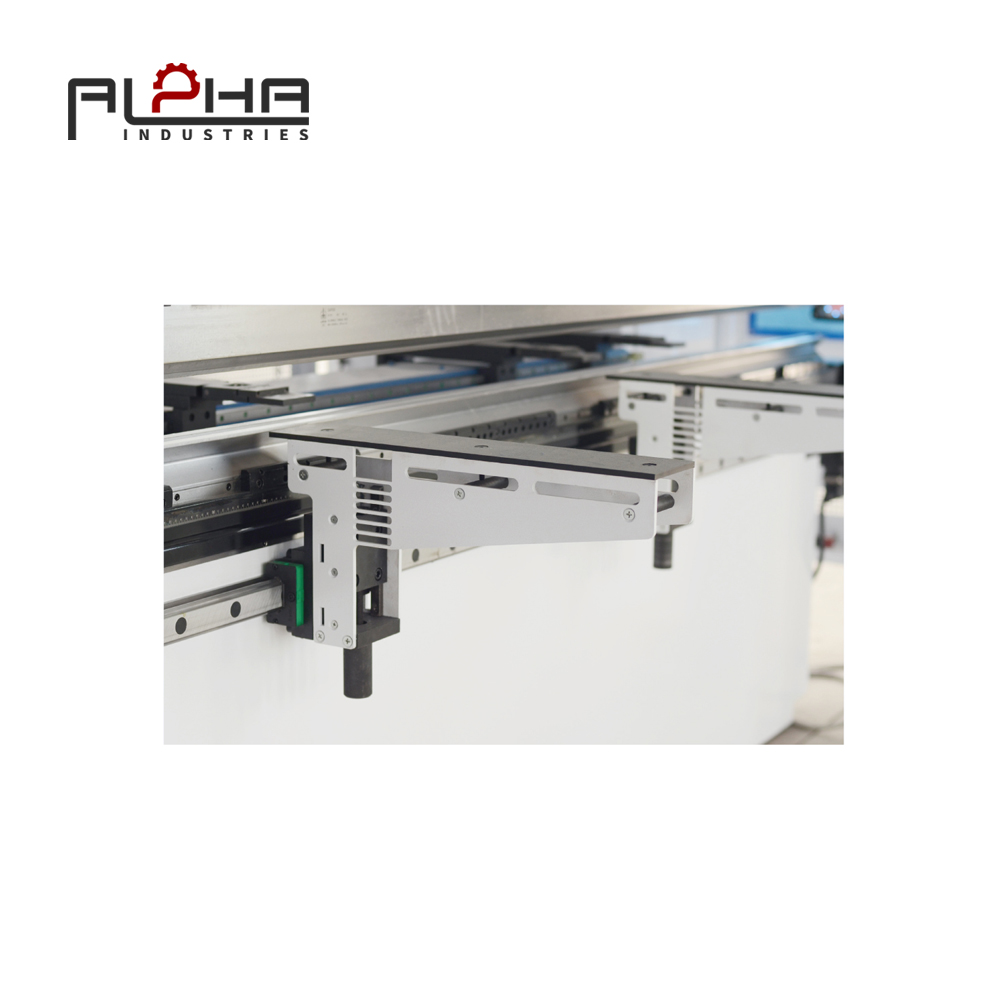

Backgauge Alignment and Positioning Accuracy

Role of the Backgauge in Dimensional Control

The backgauge system defines:

-

Bend position accuracy

-

Flange length repeatability

-

Multi-step bending consistency

Any misalignment or backlash directly translates into dimensional errors.

ALPHA Backgauge Design Principles

-

High-precision linear guides

-

Rigid support structure to prevent vibration

-

Multi-axis positioning for complex bending sequences

Result: stable and repeatable flange positioning across high-volume production.

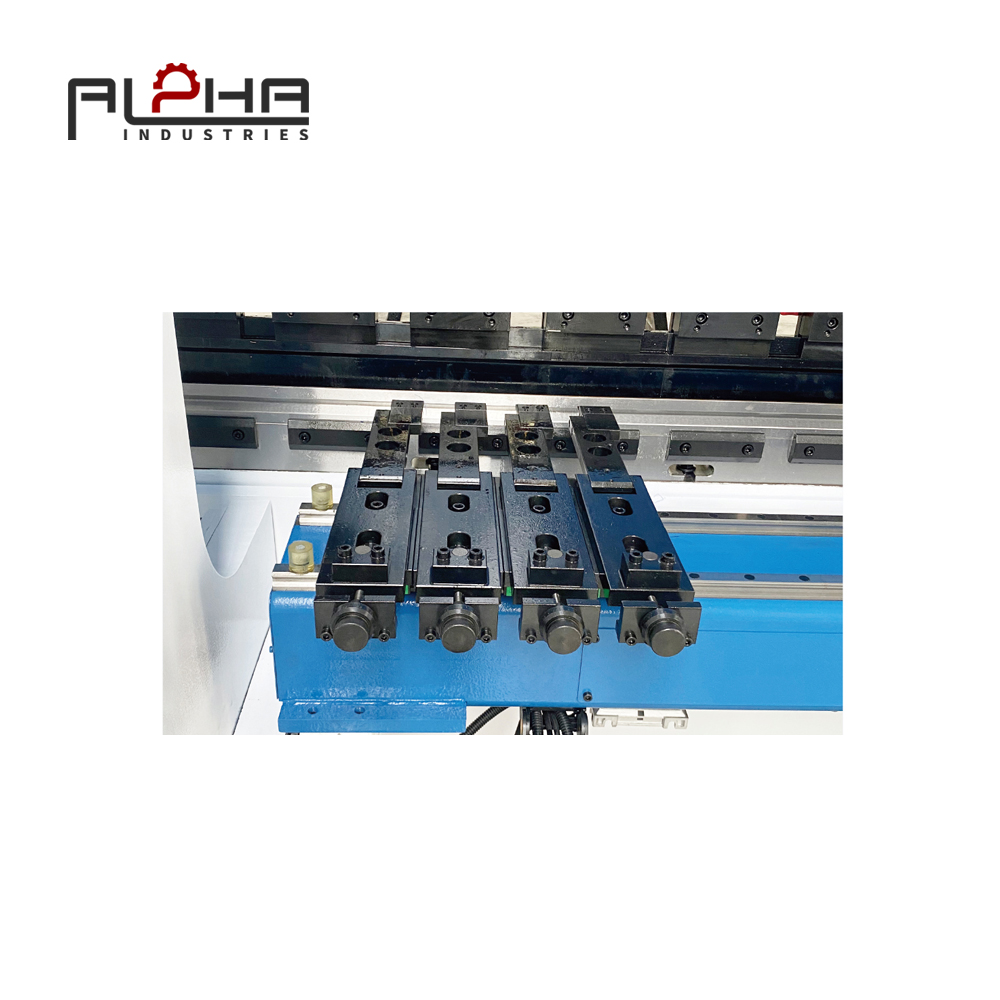

Tooling Precision — The Hidden Factor in Angle Accuracy

Tool Geometry and Surface Quality

Punch and die accuracy affects:

-

Actual bend angle

-

Material flow during forming

-

Surface finish on bent parts

ALPHA recommends:

-

Precision-ground tooling

-

Standardized tool heights

-

Consistent V-opening selection based on material thickness

Proper tooling selection reduces angle deviation and material stress.

Material Behavior and Springback Compensation

Even with a perfect machine, material springback must be addressed.

Factors influencing springback include:

-

Material tensile strength

-

Thickness variation

-

Grain direction

ALPHA press brake solutions support controlled bending strategies to compensate for springback, ensuring target angles are achieved after material recovery.

How ALPHA Achieves Stable Bending Accuracy in Production

ALPHA press brakes are engineered with a system-level accuracy philosophy, integrating:

-

Rigid machine structures

-

Precision crowning systems

-

Stable backgauge positioning

-

High-quality tooling compatibility

This holistic approach delivers repeatable bending accuracy, not just theoretical precision.

Applications That Demand High Bending Accuracy

High-accuracy press brakes are critical in:

-

Electrical cabinets and enclosures

-

Elevator and architectural components

-

Sheet metal frames and brackets

-

Precision machinery housings

In these industries, accuracy directly impacts downstream assembly efficiency.

FAQ

What determines bending accuracy on a press brake?

Bending accuracy depends on frame rigidity, crowning system, backgauge precision, tooling quality, and material behavior.

Why does a press brake bend unevenly along the length?

Uneven bending is typically caused by ram and table deflection without proper crowning compensation.

How can bending accuracy be maintained in long production runs?

Through stable machine structure, reliable positioning systems, and consistent tooling setup.

Does tooling affect press brake accuracy?

Yes. Tool geometry, alignment, and surface quality directly influence bend angle and repeatability.

Conclusion — Precision Is an Engineered Outcome

Bending accuracy is not a single feature—it is the result of engineering discipline across structure, compensation, positioning, and tooling.

By focusing on these fundamentals, ALPHA press brakes deliver stable, predictable, and production-ready bending performance for modern sheet metal fabrication.

Learn more about ALPHA Hydraulic Press Brake Solutions → /press-brake