Press Brake Laser Safety System for High-Speed and Safe Bending

In modern sheet metal fabrication, press brake laser safety systems have become a key technology for manufacturers pursuing both productivity and operator protection. Traditional light curtains and mechanical guards often force operators to slow down the bending process. A laser-based safety system, however, allows high-speed approach, precise detection, and automatic adaptation to different tooling conditions.

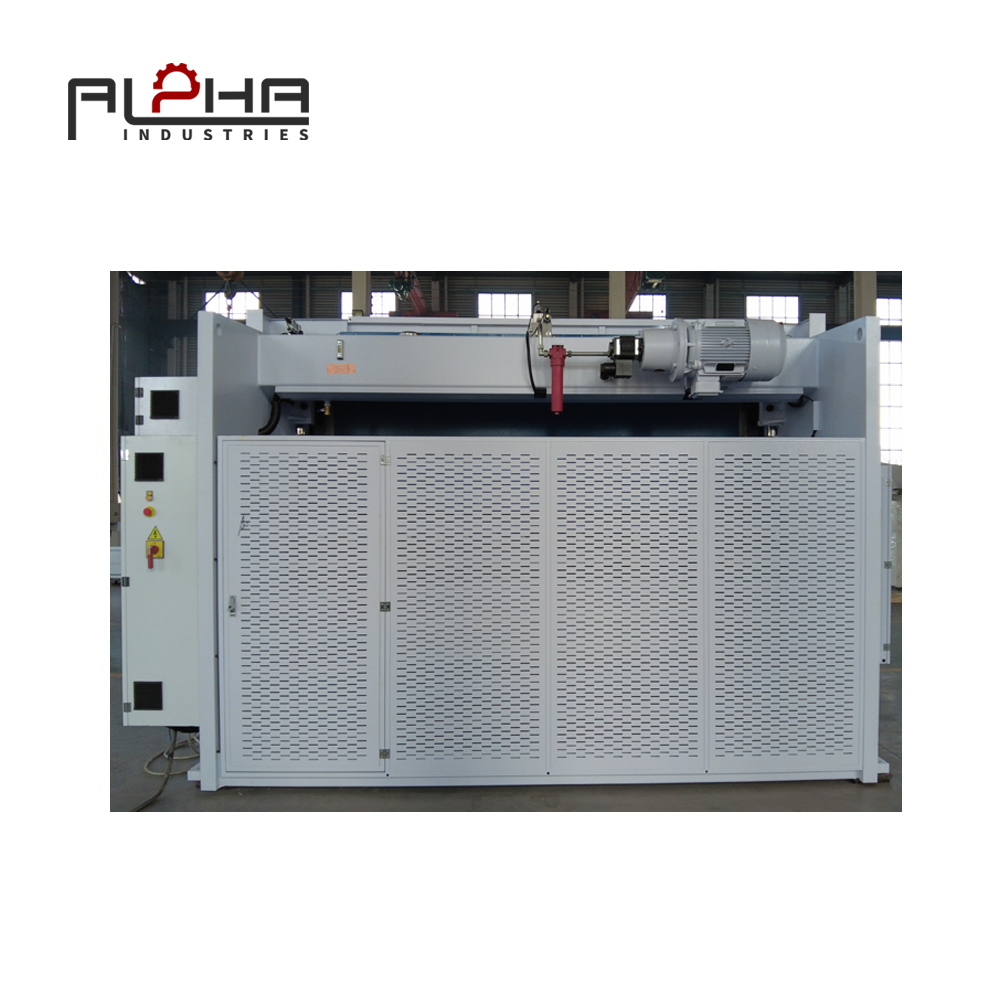

At Alpha, we integrate advanced laser safety protection into our press brake solutions to help fabricators achieve safer operations without sacrificing efficiency.

What Is a Press Brake Laser Safety System?

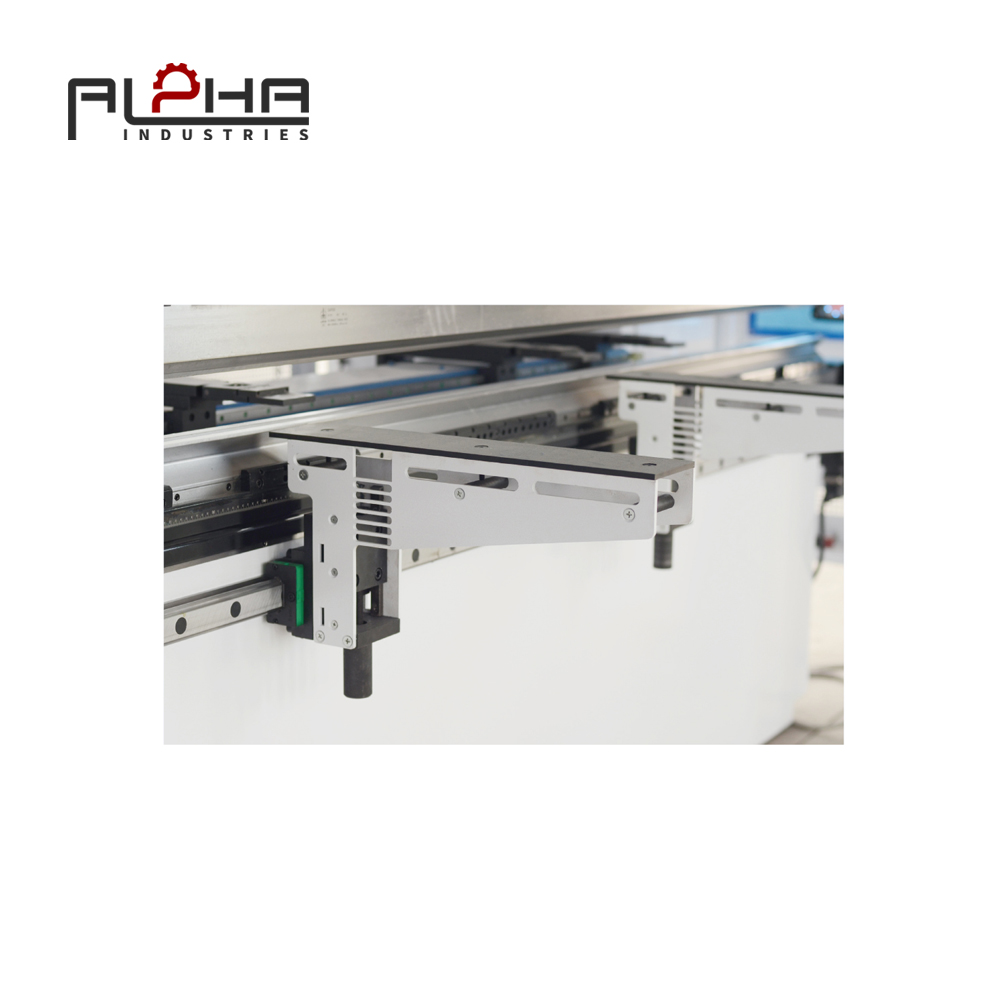

A press brake laser safety system is an optical protection device installed near the bending area. It uses synchronized laser beams to create a protective field in front of the punch and die. When an object—such as an operator’s hand—enters the protected zone, the system immediately stops or slows the machine movement.

Core Components of Laser Safety Protection

-

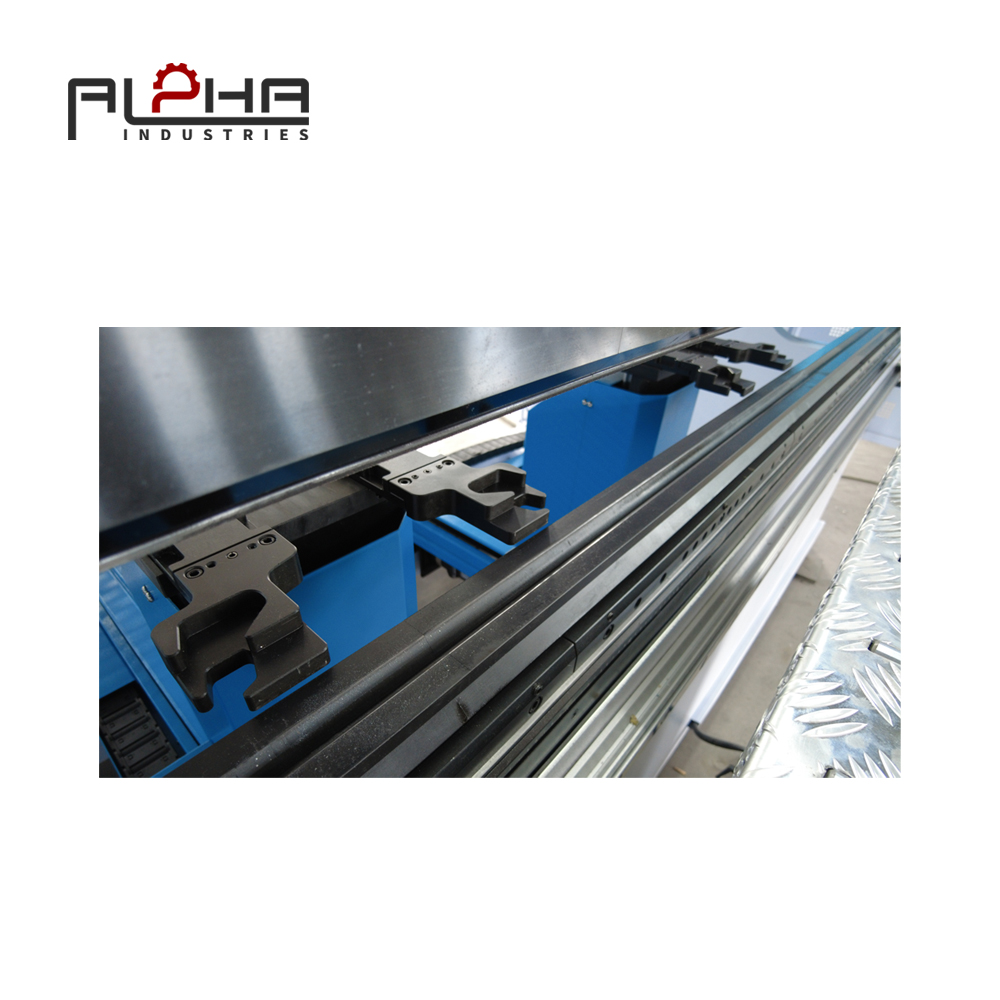

Laser transmitters and receivers mounted on both sides of the press brake

-

Real-time controller connected to the press brake CNC system

-

Adaptive logic for different tool heights and bending modes

Unlike conventional safety light curtains, laser systems are specifically designed for press brake applications and complex bending geometries.

Why Laser Safety Systems Improve Press Brake Productivity

High-Speed Approach Without Risk

With traditional protection devices, the ram speed must be reduced significantly to meet safety requirements. A press brake laser safety system allows full-speed approach until the ram reaches the safe bending zone, dramatically reducing cycle time.

Fewer Interruptions During Bending

Laser systems automatically adapt to box bending, deep profiles, and offset tools. This reduces false triggers and avoids unnecessary machine stops, ensuring smoother and more stable production.

Reduced Operator Fatigue

Because operators do not need to constantly adjust guarding devices, laser protection improves ergonomics and lowers the risk of human error during long production shifts.

Technical Advantages of Alpha Press Brake Laser Safety Solutions

Intelligent Detection Accuracy

Alpha’s laser safety systems offer millisecond-level response times and high-resolution detection. This ensures reliable protection even during high-speed bending cycles.

Seamless CNC Integration

Our press brake laser safety system is fully integrated with the CNC controller, enabling:

-

Automatic mode switching

-

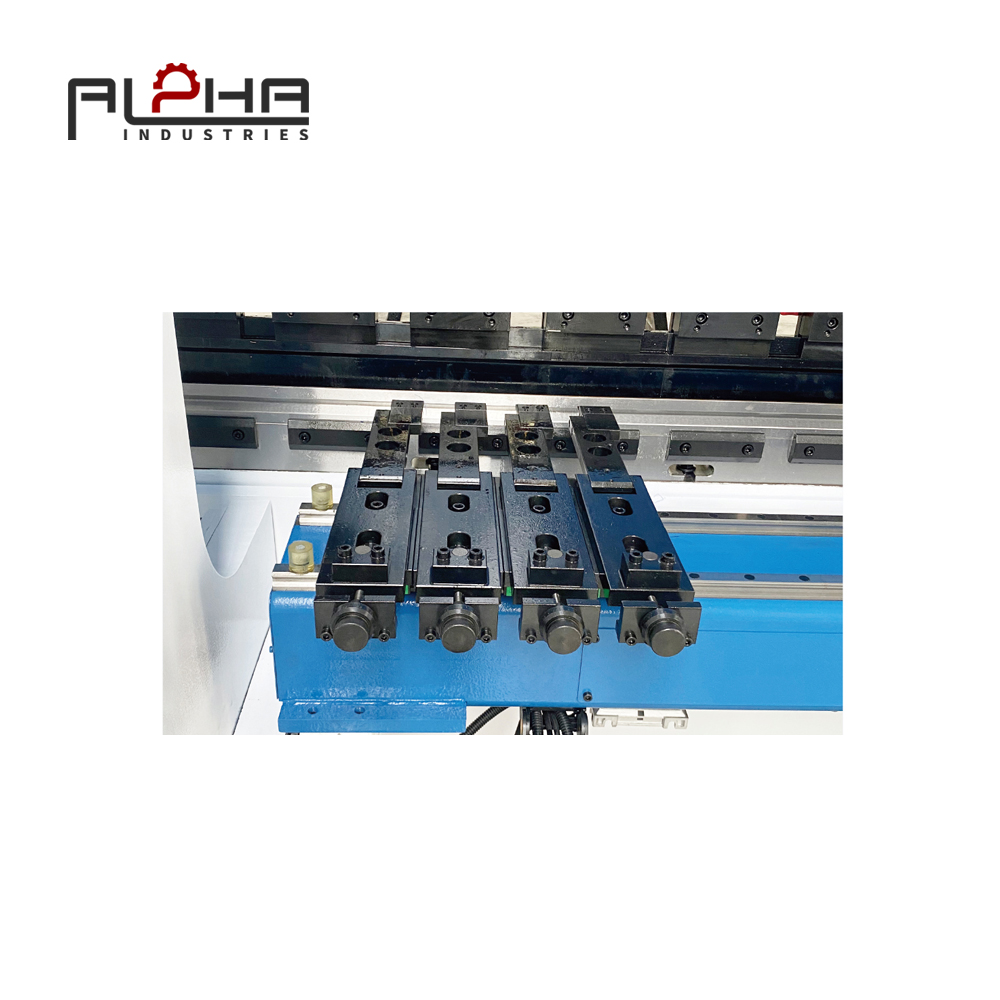

Tool recognition compatibility

-

Stable synchronization with ram movement

Compliance With International Safety Standards

Alpha press brakes equipped with laser protection are designed to meet major international safety regulations, supporting global market requirements.

Application Scenarios for Laser-Protected Press Brakes

Laser safety systems are especially valuable in:

-

High-volume sheet metal bending lines

-

Complex box and enclosure fabrication

-

Automotive and electrical cabinet production

-

Workshops requiring frequent tool changes

For manufacturers aiming to balance speed, safety, and flexibility, laser protection is no longer optional—it is a competitive advantage.

FAQ

Is a laser safety system better than a light curtain for press brakes?

Yes. Laser safety systems are specifically engineered for press brake bending, allowing closer installation to the tooling area and enabling faster approach speeds compared to standard light curtains.

Does a laser safety system affect bending accuracy?

No. When properly integrated, the system does not interfere with ram positioning or angle accuracy. In fact, stable operation can improve overall bending consistency.

Can laser safety systems work with different punch and die setups?

Yes. Advanced systems automatically adapt to various tool heights and bending geometries, making them ideal for flexible production environments.

Why Choose Alpha Press Brakes With Laser Safety Protection?

Alpha focuses on combining mechanical rigidity, intelligent control, and advanced safety technologies. Our press brake laser safety systems are not add-ons, but fully engineered solutions designed for long-term reliability and real production efficiency.

By choosing Alpha, manufacturers gain:

-

Safer working conditions

-

Shorter cycle times

-

Higher equipment utilization

-

Stronger compliance for international markets