A tube bending machine, also known as a pipe bender, is specialized equipment designed for bending metal tubes and pipes into precise radii and complex shapes. This technology is critical in industries such as automotive, aerospace, shipbuilding, HVAC, furniture, and energy, where accuracy and durability are essential.

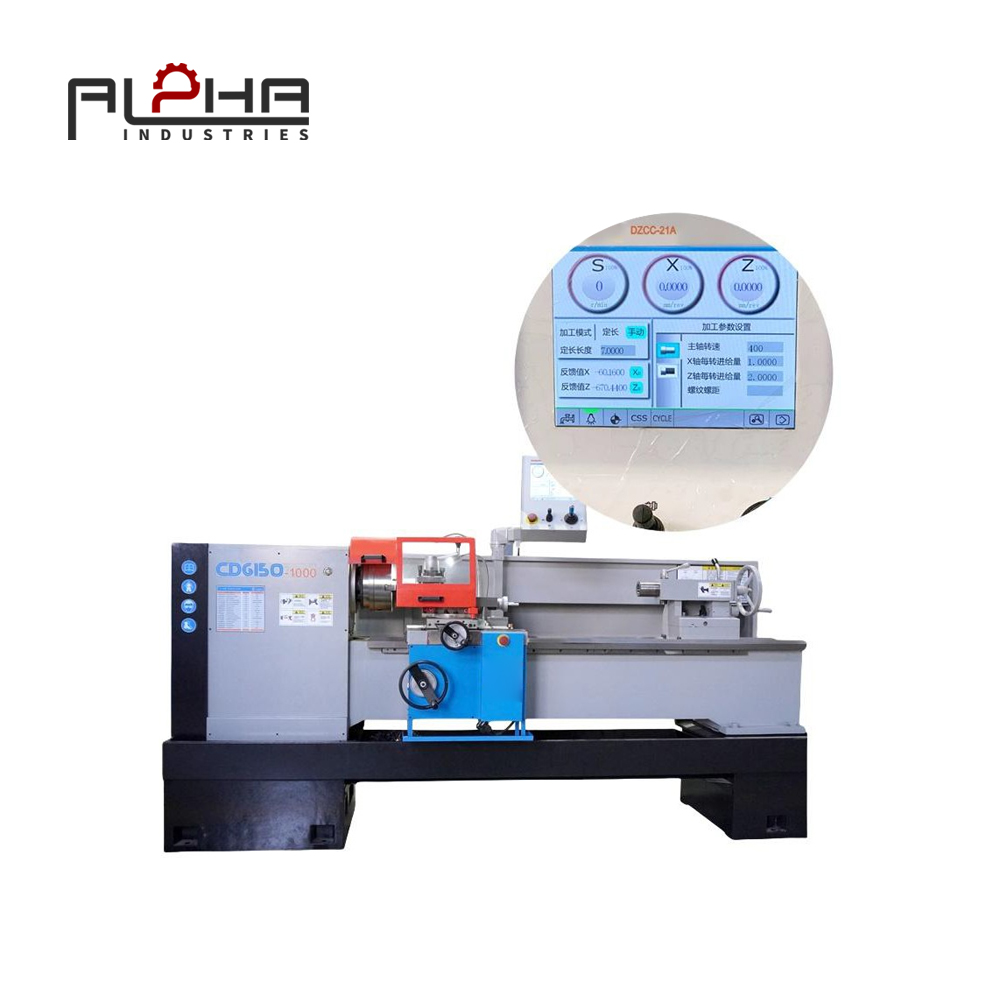

At Alpha, we manufacture high-performance tube bending machines that combine hydraulic power, CNC automation, and servo-electric control to deliver exceptional bending accuracy, repeatability, and efficiency.

Key Features of Tube Bending Machine

High Precision and Repeatability

Alpha’s machines ensure consistent bend angles and radii, supported by advanced CNC systems and intelligent programming.

Multi-Radius and Complex Bending

With interchangeable tooling, our machines can handle single-radius, multi-radius, and compound bending, making them suitable for complex applications.

Robust Hydraulic and Servo Drive Options

Hydraulic systems provide high tonnage for thick pipes, while servo-electric drives improve energy efficiency and precision.

Automated Operation

Equipped with touchscreen interfaces and CNC programming, Alpha’s tube bending machines reduce manual adjustments and setup times.

Working Principle of Tube Bending Machine

The machine clamps the pipe securely, applies force through a bending die, and rotates the pipe around the die radius to achieve the required bend angle.

-

Hydraulic Tube Bending Machines – suitable for heavy-duty industrial use and large-diameter tubes.

-

CNC Tube Bending Machines – support automation, complex geometries, and reduced cycle times.

-

Servo-Electric Tube Benders – energy-saving, precise, and ideal for high-precision industries.

Applications of Tube Bending Machine

-

Automotive – exhaust systems, chassis frames, and roll cages.

-

Aerospace – lightweight tubing for fuel and hydraulic systems.

-

Shipbuilding – piping systems, handrails, and structural tubes.

-

HVAC and Energy – heat exchanger tubes, boiler pipes, and gas pipelines.

-

Furniture – steel and aluminum tubing for chairs, tables, and frames.

Advantages of Choosing Alpha Tube Bending Machine

-

CE-certified safety standards for global compliance

-

Customizable tooling for different diameters and wall thicknesses

-

Global export service with short lead times

-

After-sales technical support with remote guidance and spare parts supply

Frequently Asked Questions (FAQ) on Tube Bending Machine

What is the function of a tube bending machine?

A tube bending machine bends metal pipes and tubes into specific radii and angles without compromising structural integrity, ensuring precision for industrial applications.

How do I choose the right tube bending machine?

Consider tube diameter, wall thickness, bending radius, production volume, and automation requirements. CNC models are ideal for high-volume, complex geometries.

What industries use tube bending machines?

Industries such as automotive, aerospace, shipbuilding, HVAC, furniture, and energy rely on tube bending machines for efficient and accurate pipe forming.

What is the difference between hydraulic and CNC tube bending machines?

-

Hydraulic machines: provide strong force for heavy-duty bending of thick pipes.

-

CNC machines: enable programmable automation, faster cycle times, and complex multi-radius bending.

Can Alpha provide customized tube bending solutions?

Yes, Alpha offers custom designs, tooling, and automation features tailored to the needs of global customers across different industries.

Why Choose Alpha Tube Bending Machine

Alpha delivers cutting-edge tube bending machines engineered for durability, precision, and efficiency. Whether for small workshops or global-scale manufacturing, our machines are designed to optimize productivity and meet international standards.

Get in touch with our team today: Contact Us