Why Flat Bed Rigidity Defines CNC Lathe Performance

In modern turning operations, CNC lathe performance is no longer judged only by spindle speed or control accuracy.

Under real cutting conditions—especially in steel, alloy, and large-diameter workpieces—flat bed rigidity becomes the decisive factor.

A CNC Lathe Flat Bed is designed to provide a stable, vibration-resistant foundation for turning operations. At ALPHA, flat bed CNC lathes are engineered with a clear objective:

maintain accuracy and surface quality under continuous cutting load.

What Is a CNC Lathe Flat Bed Structure?

A flat bed CNC lathe features a horizontally oriented, box-type bed structure with wide contact surfaces between the carriage and bed.

Compared to inclined or slant bed designs, the flat bed structure offers:

-

Larger load-bearing area

-

Higher structural stiffness

-

Better vibration absorption

-

Superior stability for heavy cutting

This makes flat bed CNC lathes especially suitable for long shafts, large parts, and heavy-duty turning.

Why Rigidity Is the Core Advantage of Flat Bed CNC Lathes

Structural Rigidity Under Cutting Load

During turning, cutting forces act continuously on:

-

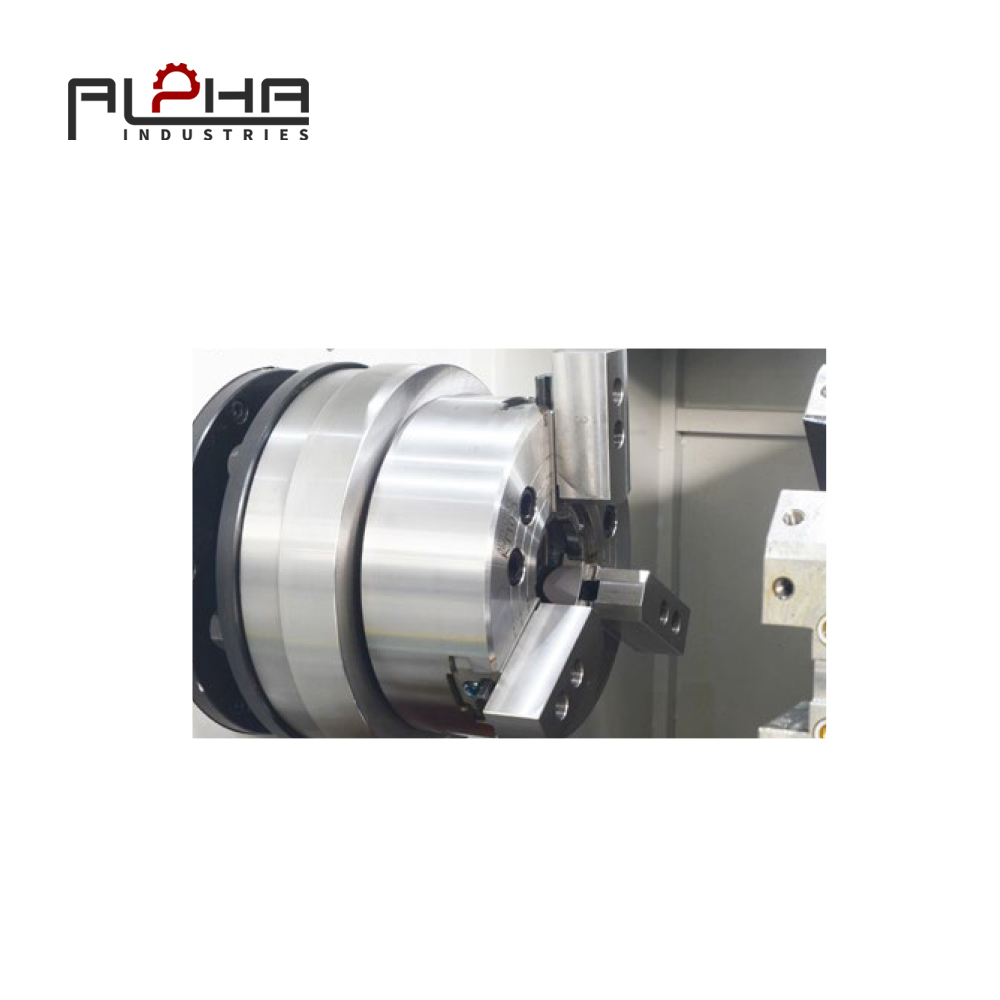

Spindle and chuck

-

Tool post and carriage

-

Bed and base

If the lathe bed lacks rigidity, these forces lead to:

-

Micro-deflection

-

Tool chatter

-

Dimensional deviation

-

Poor surface finish

A high-rigidity flat bed CNC lathe resists deformation, ensuring consistent cutting geometry throughout the machining cycle.

Flat Bed Casting Design and Stress Distribution

One-Piece High-Mass Bed Casting

ALPHA CNC lathe flat beds are manufactured using:

-

High-grade cast iron

-

Thick-wall bed sections

-

Optimized internal ribbing

This design allows cutting forces to be evenly distributed across the bed, reducing localized stress concentration.

Stress-Relieved Structure

Thermal and mechanical stress relief during casting ensures:

-

Long-term dimensional stability

-

Reduced deformation during continuous operation

-

Reliable accuracy over the machine’s service life

Guideway Contact Area and Turning Stability

Wide Guideway Layout

Flat bed CNC lathes offer wide guideway spacing, which provides:

-

Strong resistance to torsional forces

-

Stable carriage movement under load

-

Improved straightness during longitudinal turning

This is critical when machining long or heavy workpieces.

Guideway Types and Application Matching

Depending on application requirements, ALPHA flat bed CNC lathes utilize:

-

Hardened box guideways for heavy cutting

-

Precision-ground guide surfaces for smooth motion

The result is stable axis movement without vibration-induced wear.

Vibration Control and Surface Finish Quality

Why Vibration Control Matters in Turning

Vibration directly affects:

-

Surface roughness

-

Tool wear rate

-

Dimensional consistency

The high mass and damping characteristics of a flat bed CNC lathe naturally suppress vibration, producing:

-

Cleaner surface finishes

-

Reduced chatter marks

-

Extended tool life

This is especially important for finishing passes and tight-tolerance components.

Flat Bed CNC Lathe vs Slant Bed CNC Lathe (Rigidity Perspective)

| Aspect | Flat Bed CNC Lathe | Slant Bed CNC Lathe |

|---|---|---|

| Structural rigidity | Higher | Moderate |

| Heavy cutting | Excellent | Limited |

| Vibration damping | Strong | Weaker |

| Chip evacuation | Moderate | Better |

| Large workpieces | Ideal | Less suitable |

For rigidity-driven applications, flat bed CNC lathes remain the preferred solution.

Applications That Benefit Most from Flat Bed CNC Lathe Rigidity

High-rigidity CNC lathe flat bed machines are widely used in:

-

Steel shaft and bar turning

-

Heavy flange and coupling machining

-

Oil & gas components

-

Large industrial fittings

-

Maintenance and repair workshops

In these scenarios, cutting stability directly impacts productivity and accuracy.

FAQ

What does “flat bed” mean in a CNC lathe?

A flat bed refers to a horizontal bed structure that provides a wide, rigid foundation for turning operations.

Why is flat bed rigidity important?

Higher rigidity reduces vibration, improves accuracy, and ensures stable cutting under heavy loads.

Is a flat bed CNC lathe suitable for precision machining?

Yes. With sufficient rigidity and proper guideway design, flat bed CNC lathes deliver excellent dimensional consistency.

Can software compensate for poor lathe bed rigidity?

No. Rigidity is a mechanical property that cannot be corrected by CNC control systems.

Structural Rigidity vs Nominal Accuracy

A CNC lathe may show high positioning accuracy without load.

However, only a rigid flat bed structure can maintain that accuracy during real cutting.

At ALPHA, CNC lathe performance is evaluated based on cutting-condition accuracy, not just specification-sheet values.

Flat Bed Rigidity Defines Real CNC Turning Capability

A CNC Lathe Flat Bed is not an outdated design—it is a rigidity-focused solution for demanding turning applications.

By prioritizing structural stiffness, vibration damping, and load stability, ALPHA flat bed CNC lathes deliver:

-

Reliable machining accuracy

-

Superior surface finish

-

Long-term production stability

For industries where turning performance matters under real cutting conditions, flat bed rigidity defines true capability.

👉 Learn more about ALPHA CNC Lathe Solutions

/cnc-lathe