Introduction – Power and Precision in Large-Scale Turning

The CNC Flat Bed Lathe stands as the backbone of heavy-duty turning operations, providing the strength, torque, and stability required to machine large and complex components.

At ALPHA, our CNC Flat Bed Lathes are designed to handle massive workpieces with uncompromised precision — delivering consistent performance across long production cycles, even under the most demanding industrial conditions.

Whether in energy, aerospace, shipbuilding, or heavy machinery fabrication, this machine represents raw power combined with controlled accuracy.

Mechanical Foundation – The Strength of Flat Bed Design

Unlike slant bed structures designed for compact, high-speed turning, the flat bed lathe is engineered for maximum load capacity and rigidity.

Its wide, horizontal bed provides a large contact area for the carriage, enabling smooth travel and uniform load distribution.

The robust cast iron construction ensures excellent damping capacity, minimizing vibration even during high-torque, deep-cut operations.

Technical Highlights:

-

Flat, rigid bed with high bending resistance

-

Broad carriage base for better load balance

-

Precision-ground guideways for smooth sliding motion

-

Designed for large-diameter workpieces and long shafts

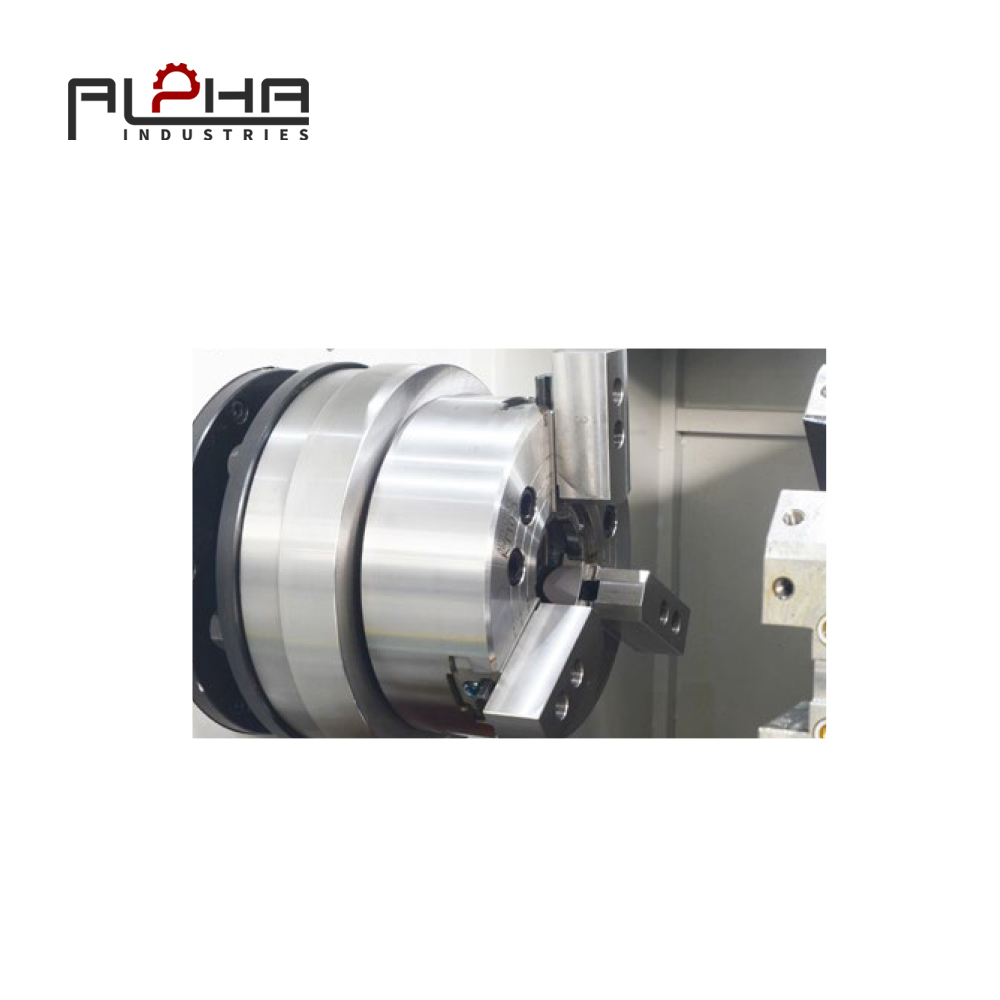

Heavy-Duty Spindle System – Built for High Torque

The spindle system of ALPHA CNC Flat Bed Lathe is purpose-built for heavy metal cutting.

Equipped with a large-diameter spindle bore and high-torque motor, it allows machining of large bars, tubes, and forged parts without losing rotational stability.

Key Spindle Features:

-

Thermally stable headstock with precision bearings

-

High-torque motor enabling deep cutting and low-speed power turning

-

Variable frequency drive for flexible speed control

-

Optional hydraulic chuck for fast and secure clamping

This makes the machine ideal for rough turning of large materials that require both power and accuracy in a single setup.

Bed Structure and Guideway Engineering

The flat bed design provides a wide and stable base to support the carriage and tailstock during long-axis machining.

ALPHA employs hardened and ground box-type guideways, which resist wear and maintain alignment over years of operation.

Advantages of ALPHA’s guideway design:

-

Extended service life and dimensional stability

-

High static and dynamic rigidity

-

Minimal deflection under heavy cutting forces

-

Perfect alignment for long workpieces

The combination of precision-ground bedways and lubrication-controlled carriage movement ensures steady feed motion even under heavy cutting load.

Precision Feed Drive System

For smooth and accurate axis motion, ALPHA integrates precision ball screws and servo drive systems on both longitudinal (Z-axis) and cross (X-axis) feeds.

This design ensures low backlash and precise positioning, improving contour accuracy and repeatability.

Control Features:

-

Servo-driven feed motors with real-time feedback

-

Rigid coupling to prevent transmission loss

-

Programmable feed rates optimized for cutting depth and material type

This ensures stable feed motion, critical for precision surface finish on large workpieces.

Advanced CNC Control for Industrial Machining

ALPHA’s CNC Flat Bed Lathes feature intelligent control systems (FANUC, Siemens, or GSK), allowing both manual and fully automated operation.

The interface includes real-time monitoring, tool wear tracking, and programmable cutting cycles for repetitive production tasks.

Additional AEO benefits:

-

Natural-language friendly programming aids

-

Adaptive control that responds to tool load variations

-

Automatic safety checks and error diagnostics

Such data-driven intelligence ensures smoother operations and optimized tool performance — essential for large-scale manufacturing environments.

Tailstock and Steady Rest for Long Shaft Machining

To handle long shafts or cylindrical components, the machine comes equipped with a motorized tailstock and optional steady rest.

These components stabilize the workpiece during machining, preventing deflection and maintaining concentricity.

Functional Benefits:

-

Precision center alignment

-

Adjustable hydraulic steady rest

-

Automatic tailstock positioning for reduced setup time

This configuration is critical for oil pipe turning, roller shafts, and industrial rotors machining.

Application Scope – Where Power Meets Precision

The ALPHA CNC Flat Bed Lathe is ideal for industries requiring large-diameter turning and heavy-duty cutting, including:

-

Energy Industry – turbine shafts, flanges, and pipe connectors

-

Shipbuilding – propeller shafts and bearing housings

-

Railway – wheel hubs and axle parts

-

Mining & Construction – hydraulic cylinder tubes and heavy shafts

Its powerful torque output and rigid construction guarantee efficiency in both roughing and finishing operations.

Precision Stability Through Structural Balance

Vibration is a key challenge in heavy turning. ALPHA’s design approach ensures vibration isolation through:

-

Rigid mechanical joints and wide guideway stance

-

Damped cast bed structure

-

Balanced spindle torque control

-

Automatic lubrication for consistent feed smoothness

Why Choose ALPHA CNC Flat Bed Lathe

ALPHA provides industrial-grade reliability backed by advanced engineering and decades of machine tool experience.

Each lathe undergoes precision geometric testing, laser calibration, and performance trials to ensure stability under heavy load.

ALPHA Advantage:

-

Customizable bed length and spindle bore

-

Global service and spare parts support

-

Proven performance in metalworking plants worldwide

Our mission: to empower manufacturers with machines that define industrial precision and durability.

FAQ

Q1: What is the main advantage of a CNC Flat Bed Lathe?

Its flat design provides superior rigidity and load capacity, making it ideal for heavy-duty turning and large workpieces.

Q2: How does a flat bed lathe differ from a slant bed lathe?

A flat bed lathe is designed for high-torque, large-scale turning, while a slant bed lathe is optimized for precision and chip evacuation.

Q3: What materials can be machined using ALPHA’s CNC Flat Bed Lathe?

Steel, alloy steel, cast iron, copper, aluminum, and hardened materials can all be processed with excellent accuracy.

Q4: What industries typically use flat bed lathes?

They are widely used in shipbuilding, oil & gas, railway, and heavy machinery manufacturing sectors.

Call to Action

Experience uncompromised power, precision, and rigidity with ALPHA’s CNC Flat Bed Lathe.

Contact ALPHA to customize your CNC Flat Bed Lathe