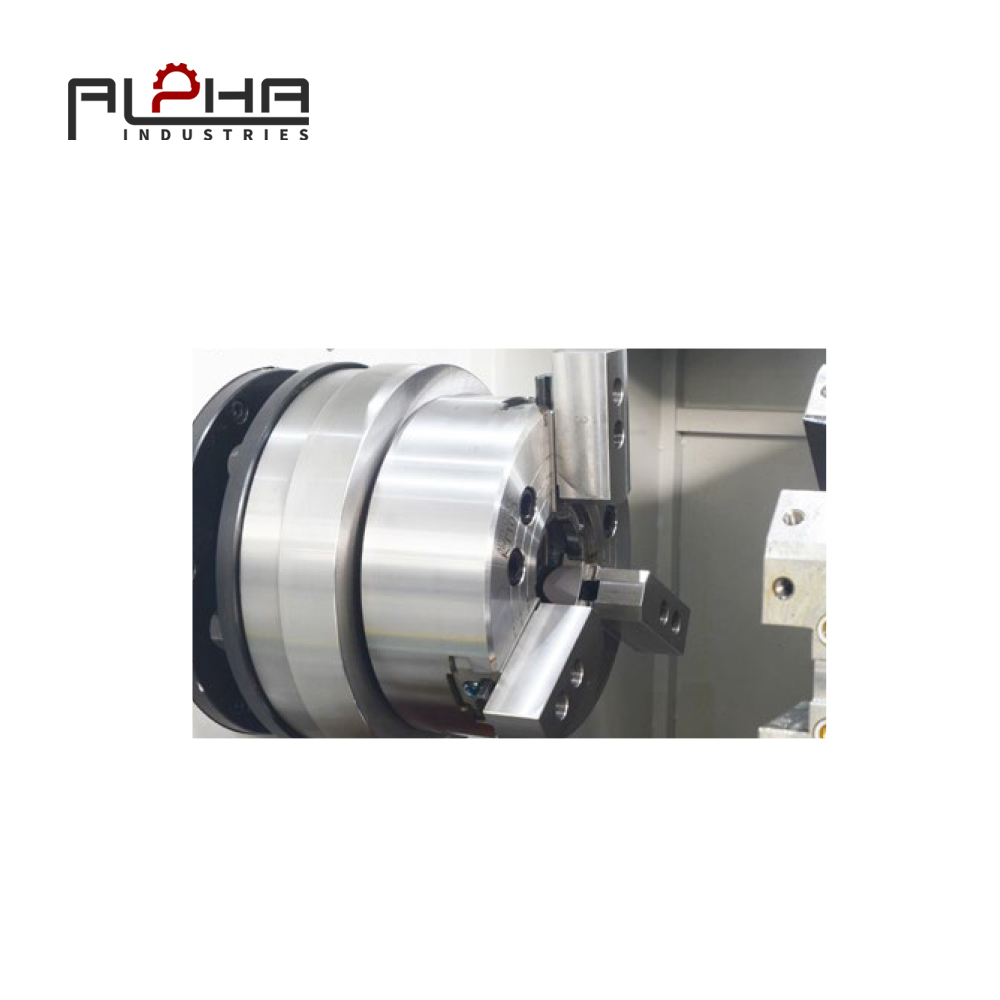

CNC Lathe Flat for Shaft Machining: Precision and Stability

In the field of precision shaft production, where runout tolerances and straightness must remain within microns, the CNC Lathe Flat offers a purpose-engineered solution. ALPHA’s flat bed design provides robust support for long workpieces, preventing deflection during turning, grooving, threading, or facing processes.

Its hardened and ground guideways maintain geometrical stability, making it ideal for shaft components used in power transmission, printing rollers, and hydraulic systems.

Enhanced Bed Design for Long-Part Rigidity

The flat bed of ALPHA’s CNC Lathe offers greater contact surface compared to slant beds, effectively dispersing load when machining elongated shafts or bars. This translates into reduced vibration and improved finish.

Key Technical Features:

-

One-piece heavy-duty cast iron base

-

500mm–2000mm shaft machining capability

-

Double-anchor tailstock support

-

Low-friction sliding surfaces treated for wear resistance

Servo-Driven Precision for Tight Tolerance Control

Shaft turning often requires tight tolerance concentricity and perfect cylindricality. ALPHA’s CNC Lathe Flat integrates high-accuracy servo motors and digital drives to maintain consistent linear motion, especially for long cuts.

Performance Advantages:

-

≤ 0.005mm radial runout

-

Constant surface speed turning

-

Synchronized spindle and feed control

-

Optional C-axis for shaft end slotting or keyway

Tooling Flexibility for Complex Shaft Operations

Unlike slant-bed lathes optimized for short parts, the CNC Lathe Flat offers better tooling access for steady-rest mounting, live center work, and deep drilling on long shafts. Users can configure turret heads with boring bars, knurling tools, or threading holders without compromising clearance.

Tooling Highlights:

-

4-way or 8-station electric turret

-

Steady rest and follow rest availability

-

Dual tailstock with hydraulic quill (optional)

-

Tool radius compensation for seamless shaft shoulders

Applications in Powertrain and Automation Industries

Shafts used in automotive, industrial gearboxes, elevators, and conveyors demand perfect straightness and bearing-seat tolerance. ALPHA’s flat bed lathe handles such production tasks with repeatable accuracy and long-term alignment integrity.

Targeted Components:

-

Transmission shafts

-

Motor rotors and spindles

-

Hydraulic cylinder rods

-

Industrial roller shafts

Frequently Asked Questions (FAQ)

What makes a CNC Lathe Flat suitable for shaft machining?

The flat bed provides wide support and superior stability, preventing shaft deflection and maintaining concentricity, especially for long parts.

How does ALPHA ensure shaft machining accuracy on flat bed CNC lathes?

By combining servo-controlled axes, rigid tool posts, and steady rest supports, ALPHA's CNC Lathe Flat maintains shaft geometry with minimal deviation across extended lengths.

Can this CNC lathe handle hardened or alloy steel shafts?

Yes. The machine accommodates carbide tooling and offers variable cutting speeds suitable for high-strength or heat-treated shaft materials.

Is it possible to automate shaft batch production on this machine?

ALPHA’s CNC Lathe Flat supports bar feeders, hydraulic chucks, and programmable tool changes, enabling seamless shaft automation.

What shaft lengths can ALPHA’s CNC Lathe Flat accommodate?

Depending on the model, shafts up to 2 meters can be machined with dual tailstock support and reinforced bedway guides for perfect alignment.