Why Flat Bed CNC Lathe Structure Matters in Precision Turning

In modern metal machining, turning accuracy is not determined only by spindle speed or control systems.

For medium to large workpieces, long shafts, and heavy cutting conditions, the machine bed structure becomes the defining factor.

This is where the CNC LATHE FLAT BED design proves its long-term value.

The Alpha CNC Lathe Flat Bed Series is engineered around one critical objective:

👉 Maintaining turning stability and dimensional consistency under continuous cutting loads

This article focuses on one decisive technical dimension—

how flat bed rigidity directly impacts machining accuracy, vibration control, and service life in CNC turning operations.

Understanding CNC Lathe Flat Bed Design

A CNC lathe flat bed features a horizontal, wide-contact bed structure, where the carriage and tailstock move along precision guideways mounted on a solid bed casting.

This structure is especially suitable for:

-

Long or heavy cylindrical workpieces

-

High cutting force applications

-

Continuous production cycles

-

Stable manual or CNC turning operations

Compared with inclined bed lathes, flat bed CNC lathes emphasize structural mass, rigidity, and vibration absorption.

Bed Rigidity: The Core Advantage of CNC Lathe Flat Bed Machines

Why Bed Rigidity Is Critical in Turning

During turning, cutting forces act continuously on the workpiece, tool, spindle, and bed.

Insufficient bed rigidity leads to:

-

Tool chatter

-

Taper errors

-

Poor surface finish

-

Dimensional drift over time

Alpha flat bed CNC lathes are designed to eliminate these risks at the foundation level.

Heavy-Duty Flat Bed Casting Structure

Alpha CNC lathe flat bed machines utilize:

-

High-strength cast iron bed construction

-

Wide bed geometry with optimized rib layout

-

Stress-relieved casting process

This design delivers:

✔ High vibration damping

✔ Minimal deformation under load

✔ Stable tool-to-workpiece alignment

The result is consistent diameter control and improved surface quality, even in heavy-duty turning.

Wide Guideway Contact for Long-Term Stability

Flat bed CNC lathes provide a larger contact area between the carriage and the bed.

Alpha designs feature:

-

Precision-machined guideways

-

Wide bearing surfaces

-

Optimized load distribution

This ensures smooth carriage travel and reduces wear concentration, maintaining accuracy over extended service life.

Vibration Control Through Mass and Geometry

Vibration is one of the main enemies of turning accuracy.

The flat bed structure naturally offers:

-

Higher machine mass

-

Lower center of gravity

-

Superior vibration absorption

Alpha CNC lathe flat bed machines leverage this advantage to achieve:

✔ Smoother cutting action

✔ Improved surface finish

✔ Reduced tool wear

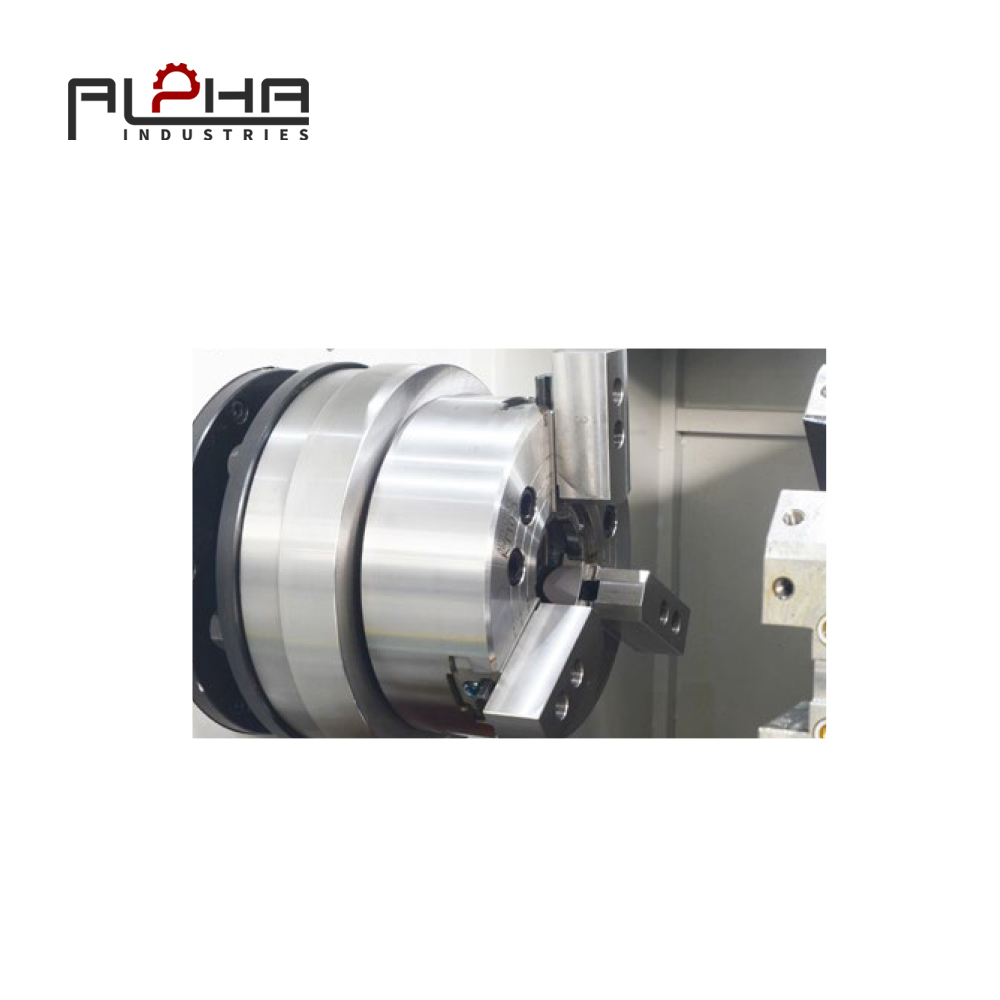

Stable Headstock and Bed Integration

Turning accuracy depends heavily on the alignment between the spindle and bed.

Alpha CNC lathe flat bed machines are engineered with:

-

Rigid headstock mounting

-

Precision-aligned bed-to-headstock interface

-

Stable spindle axis support

This ensures long-term concentricity and dimensional repeatability.

Flat Bed CNC Lathe for Heavy and Long Workpieces

The flat bed structure is especially suitable for:

-

Shafts and rods

-

Hydraulic cylinders

-

Rollers and sleeves

-

Industrial mechanical components

The rigid bed prevents deflection when machining long workpieces supported by tailstock or steady rests.

Consistent Accuracy in Continuous Production

Accuracy must be maintained not only on the first part, but throughout production.

Alpha flat bed CNC lathes deliver:

-

Stable geometry during long cycles

-

Reduced thermal and mechanical drift

-

Predictable machining results

This makes them ideal for batch production and industrial environments.

Reduced Scrap and Lower Operating Cost

Unstable machines lead to rework and material waste.

By prioritizing bed rigidity and structural stability, Alpha CNC lathe flat bed machines help manufacturers achieve:

✔ Higher first-pass yield

✔ Lower scrap rates

✔ Reduced adjustment and downtime

CNC Lathe Flat Bed Applications

Industries that benefit from flat bed CNC lathes include:

-

General metal machining

-

Industrial equipment manufacturing

-

Hydraulic and pneumatic components

-

Automotive parts machining

-

Maintenance and repair workshops

FAQ

What is a CNC lathe flat bed used for?

A CNC lathe flat bed is used for turning cylindrical metal parts, especially long or heavy workpieces that require high rigidity and stable cutting.

Why choose a flat bed CNC lathe instead of a slant bed?

Flat bed CNC lathes provide higher structural rigidity and vibration damping, making them suitable for heavy-duty and long-term turning applications.

How does bed rigidity affect turning accuracy?

A rigid bed minimizes deformation and vibration, ensuring consistent tool positioning and stable dimensional control.

Is a flat bed CNC lathe suitable for continuous production?

Yes. With proper structural design, flat bed CNC lathes maintain accuracy throughout extended production cycles.

Why Choose Alpha CNC Lathe Flat Bed Machines

Alpha focuses on engineering-driven lathe design, not generic assembly.

With Alpha CNC lathe flat bed machines, you gain:

-

Superior bed rigidity

-

Stable and accurate turning

-

Industrial-grade durability

-

Long-term dimensional consistency

Explore More Alpha Machining Solutions

👉 CNC Lathe Machine Series

https://alpha-cnc.com/products/cnc-lathe-flat

👉 All Alpha CNC & Industrial Machines

https://alpha-cnc.com/products

Contact Alpha today to discover how our CNC Lathe Flat Bed machines can improve your turning stability, accuracy, and production efficiency.