Introduction to Vertical Machine Center

In the field of CNC machining, the "vertical machine center" is the cornerstone of modern manufacturing processes. Vertical machine centers are well-known for their versatility and precision, providing unparalleled efficiency in machining tasks such as cutting, drilling and milling. For industrial applications where accuracy and adaptability are required, vertical machine centers such as Alpha's VMC500 represent the cutting-edge technology needed to stay ahead of the competitive industry.

Use VMC500 vertical machine center to improve accuracy

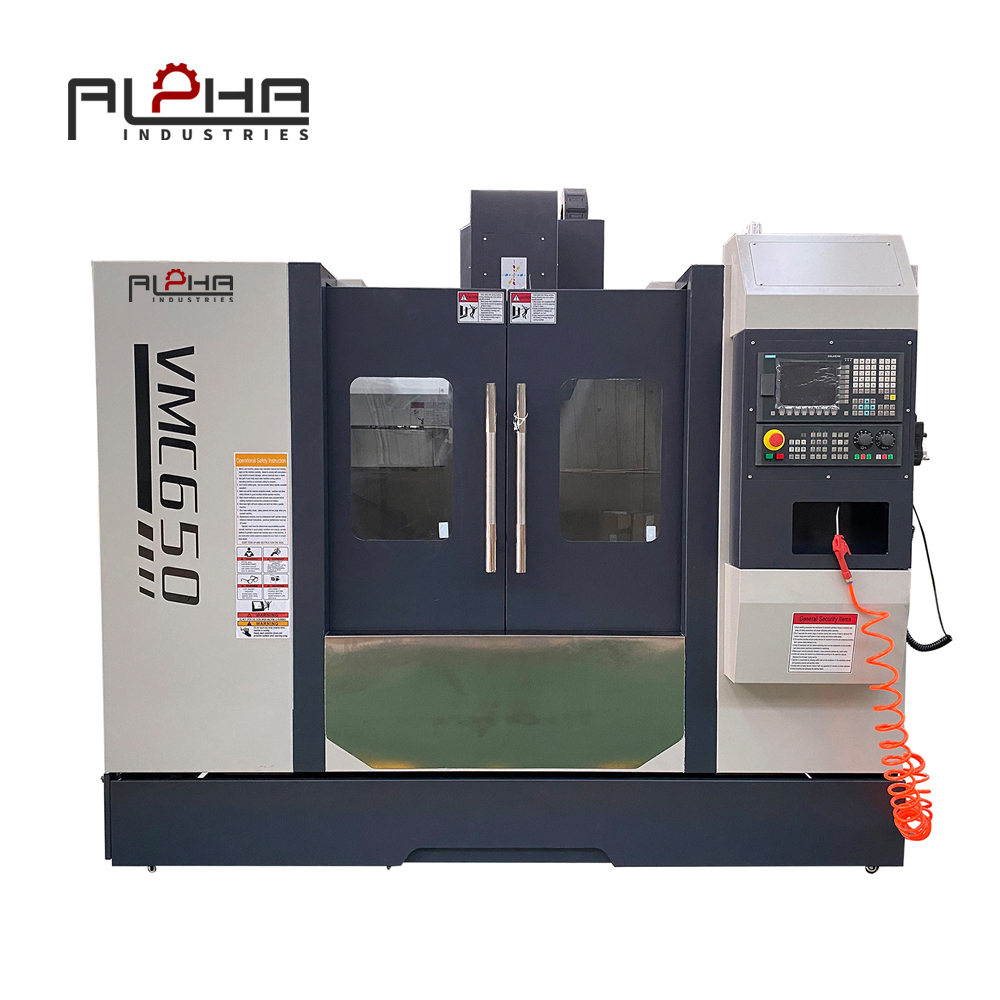

By Nanjing Alpha CNC Co., Ltd. The introduction of the VMC500 vertical machining center is a breakthrough in precision engineering. As one of the leading vertical machine center manufacturers, Alpha has injected innovation into every aspect of the VMC500. The compact and robust design ensures that the machine not only saves space but also ensures stability during high-speed machining. High-performance spindles form the heart of the VMC500, providing unparalleled cutting capabilities for a wide range of materials.

In addition to attractiveness, the VMC500 is equipped with a precisely designed linear guide tube and a rigid foundation to minimize vibration, ensuring efficiency and excellent results. Its multi-axis configuration and multi-functional working sports movement make it an ideal CNC vertical machine center for industrial applications. The adaptability of the VMC500 makes it highly sought after, especially for those who want to buy vertical machine centers for sale for automotive, aerospace, medical equipment and electronics manufacturing.

Define key functions of VMC500

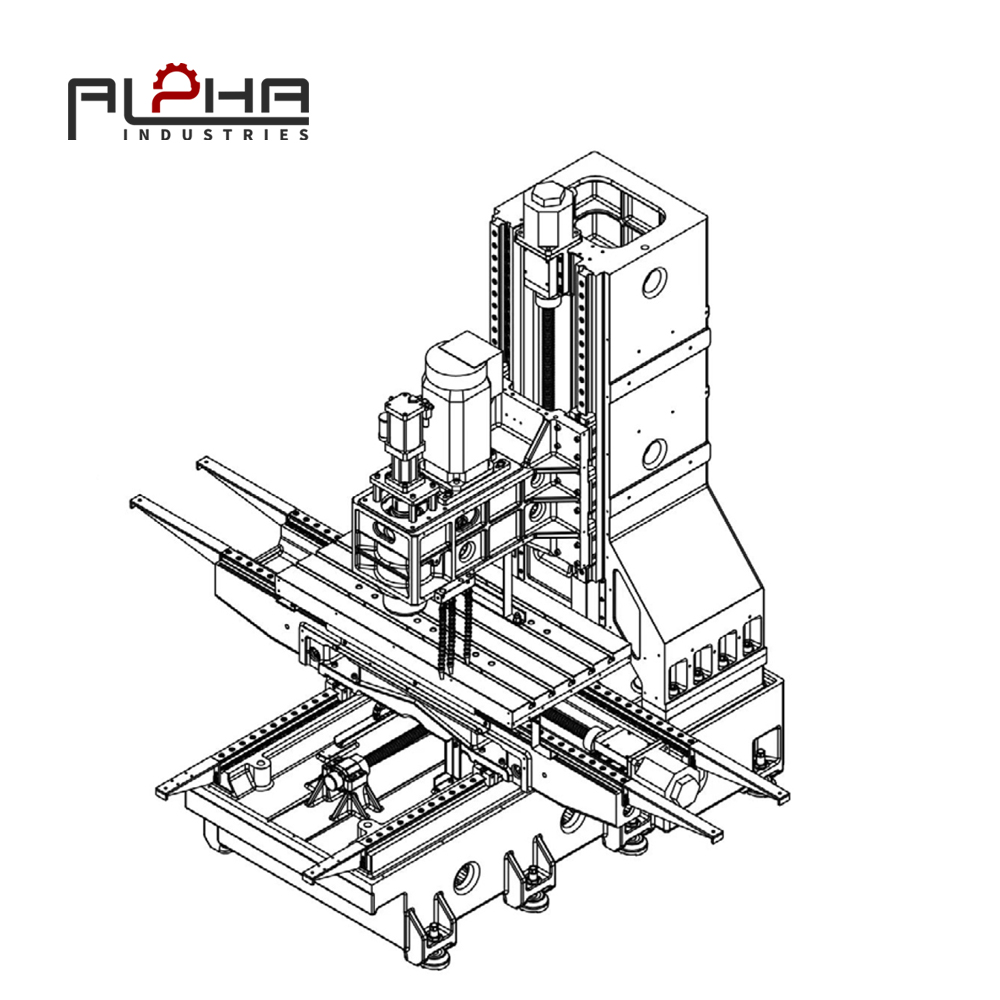

One of the most impressive aspects of the VMC500 is its innovative design and functionality. With a compact and sturdy construction, this vertical machine center highlights the perfect balance between performance and efficiency. Table motion (X, Y and Z axes) cross-cut, designed to handle complex machining tasks with ease and precision. Its advanced spindle centralizes it in symmetric load balancing, ensuring a sharp finish even with challenging materials.

In addition, the VMC500 is integrated with a sophisticated automatic tool changer (ATC), simplifying the transfer between operations. This tool management system greatly improves efficiency, which makes machines an excellent investment for manufacturers of priority productivity and precision. Engineers also include Alpha Intelligence Technology, which provides real-time monitoring, diagnostic alerts and performance tracking, a valuable addition to long-term reliability and maintenance.

Conclusion

VMC500 Vertical Machining Center is more than just a tool. It represents the pinnacle of innovation and engineering at Nanjing Alpha CNC Co., Ltd. Whether you are looking for vertical machine centers for sale or exploring the potential of used vertical machine centers, the VMC500 is the top choice. Its advanced features, modern design and unparalleled reliability make it an indispensable asset for every industry.

Trust Alpha's expertise to provide machining solutions that suit your production needs and experience new precision and efficiency in operation. Explore VMC500 and other products today to revolutionize your manufacturing process.