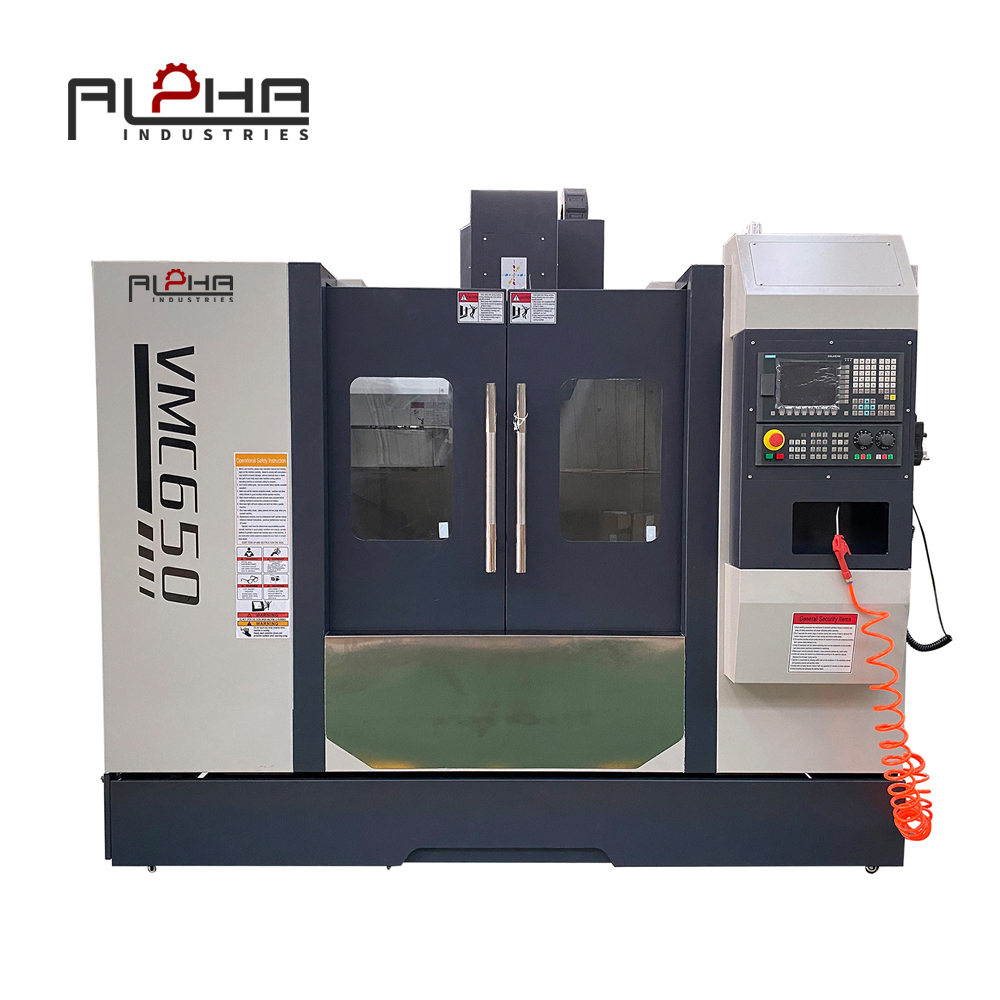

ALPHA’s vertical machine center (VMC) tailored for mold manufacturing provides exceptional performance in terms of dimensional accuracy, repeatability, and surface finish—three critical requirements in die and mold production. Mold machining demands not just precision, but high material removal rates and rigid structural design to withstand the stress of continuous operations in tool steel, hardened alloys, and other demanding materials.

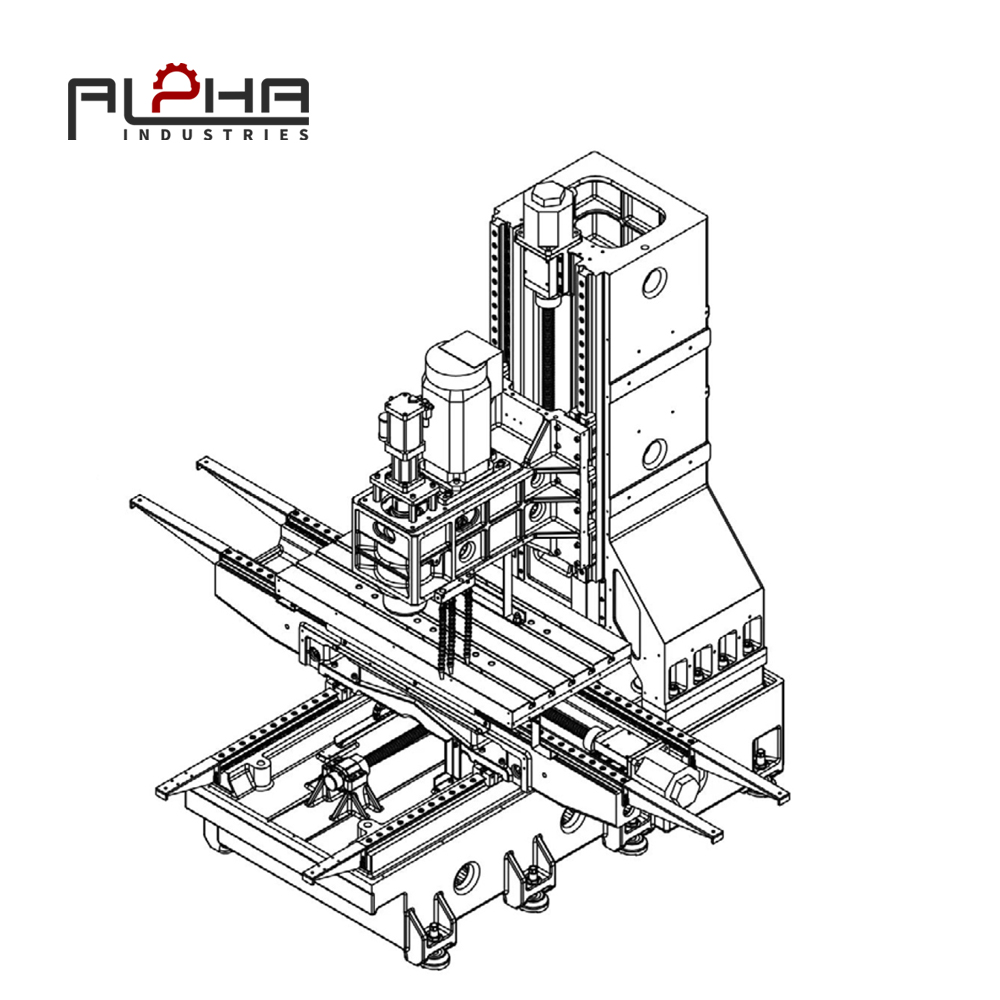

The base, column, and saddle of ALPHA’s VMC are integrally cast to provide outstanding rigidity and superior vibration dampening performance.For mold processing, where deep cavity cutting and continuous load conditions are common, this design minimizes deflection and guarantees accuracy over long machining cycles.

The fully enclosed box-way guide structure option—available for heavy-duty models—provides added resistance to torsional stress, further improving machine rigidity.

The vertical machine center features a direct-drive spindle configuration with optional motorized spindle for fine finishing operations. The spindle nose is thermally stabilized, and oil-air lubrication is employed to reduce heat build-up during high-speed operations.

ALPHA’s spindles are dynamically balanced and tested for concentricity within ±2 μm, allowing micro-finish tolerances in cavity machining without secondary grinding.

ALPHA integrates flood coolant nozzles, through-spindle coolant, and programmable misting systems, which are essential for extending tool life during deep pocket milling and fine-detail contouring. The dual-screw chip conveyor system ensures uninterrupted evacuation of chips—even from sticky materials like P20 or H13—thereby reducing downtime.

ALPHA’s VMCs are compatible with Fanuc, Mitsubishi, or Siemens controllers, and offer high-speed look-ahead and multi-axis synchronization, enabling efficient 3D surfacing, electrode machining, and engraving of fine details.

Temperature fluctuations are one of the biggest challenges in mold machining. ALPHA includes a thermal compensation module that monitors axis and spindle temperature and actively adjusts position data to ensure micron-level accuracy over extended operations. Linear scales (Heidenhain optional) are installed on the X/Y/Z axes to prevent cumulative positioning error.

The machine is designed with servo-based lubrication and variable frequency drive systems, reducing overall energy consumption. The modular layout allows technicians to access coolant tanks, electronics, and tool magazines conveniently, facilitating quicker preventive maintenance.

Whether it's plastic injection molds, die-casting tooling, stamping dies, or EDM electrode bases, ALPHA's VMC ensures the surface finish, dimensional tolerance, and production efficiency that mold industries demand.

Why Choose ALPHA's Mold-Focused VMC:

-

Cast-iron monolithic structure for stability

-

Spindle concentricity within ±2 µm

-

Thermal compensation and linear scale feedback

-

Optimized for steel, alloy, and hardened tool materials

-

Advanced cooling and chip management for long-cycle cutting

-

Flexible controller options and mold machining cycles

People Also Ask (FAQ):

What makes a VMC suitable for mold processing?

A VMC must offer high rigidity, thermal stability, fine spindle control, and advanced coolant systems to handle the demands of mold manufacturing. These features ensure accuracy during prolonged, high-load cutting cycles.

Can a vertical machine center machine hardened steel?

Yes, ALPHA’s VMC models are capable of machining hardened steels up to 60 HRC, especially when paired with coated carbide or CBN tooling and optimized cooling strategies.

How accurate is a VMC for mold machining?

With features like linear scales, thermal compensation, and high-resolution encoders, ALPHA’s VMCs can achieve accuracy within ±3 μm over long operations—ideal for mold cavity precision.

Is a vertical machine center better than a horizontal one for molds?

For complex, upright cavity structures and easier workpiece setup, vertical machine centers are often preferred. ALPHA’s VMCs provide better chip removal for vertical cavities and simpler programming for 3-axis mold machining.