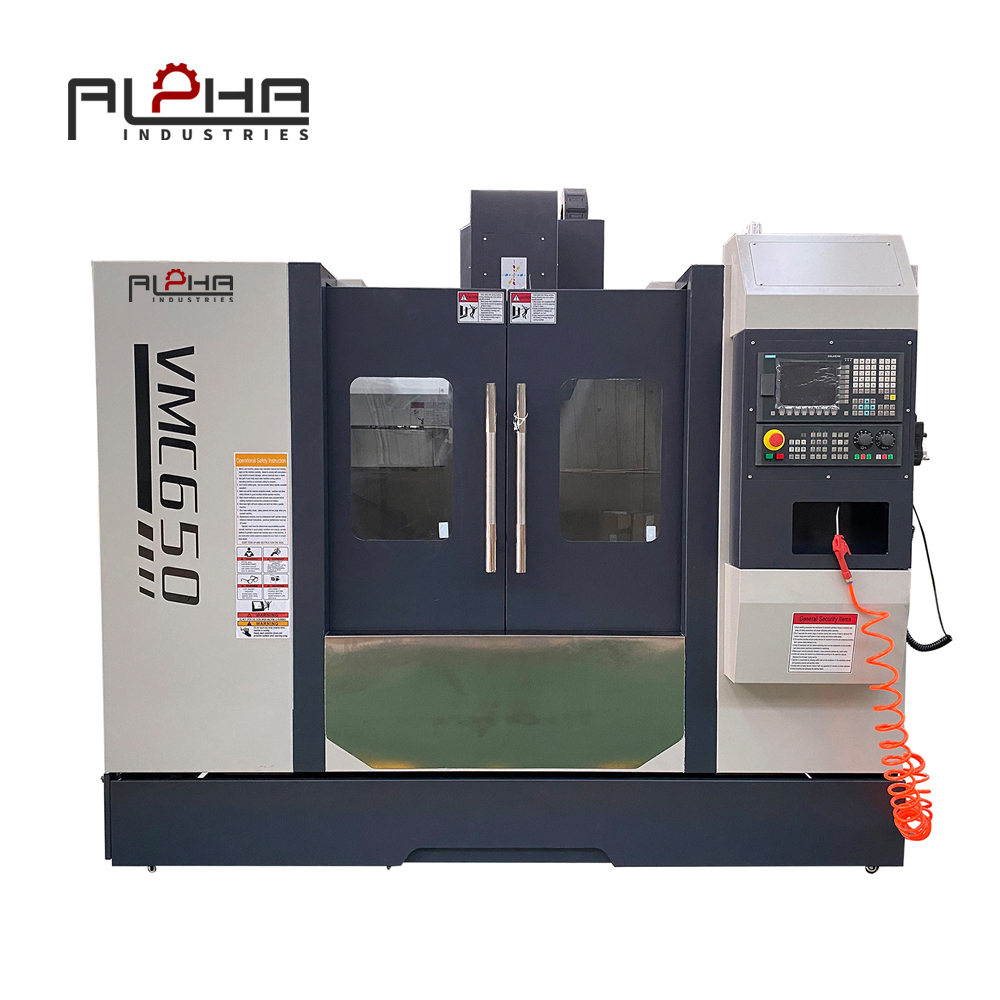

High-precision vertical machine center for aerospace components processing

As the aerospace industry requires microscopic tolerances and unparalleled surface finishes, Alpha introduces its high-precision Vertical Centre (VMC) - a solution designed to be accurate, consistent and productivity in the manufacturing of critical aerospace components.

Why does the aviation industry rely on vertical aircraft centers

Aerospace parts such as turbine blades, actuator housings and engine brackets require geometric accuracy and surface integrity. Alpha Vertical Machine Center provides:

-

Thermal stabilitythrough cast iron one-piece structure

-

Linear Guide and C3 level ball screw ensures smooth and rebound-free movement

-

Multi-axis interpolationFor complex configuration files with precise tool paths

-

Built-in cooling system Reduce thermal deformation during long cycles

These functions enable VMC to achieve ±2 µm positioning accuracy and ±1 µm repeatability makes it ideal for aviation-grade parts production.

Main features of the vertical machine center of Alpha

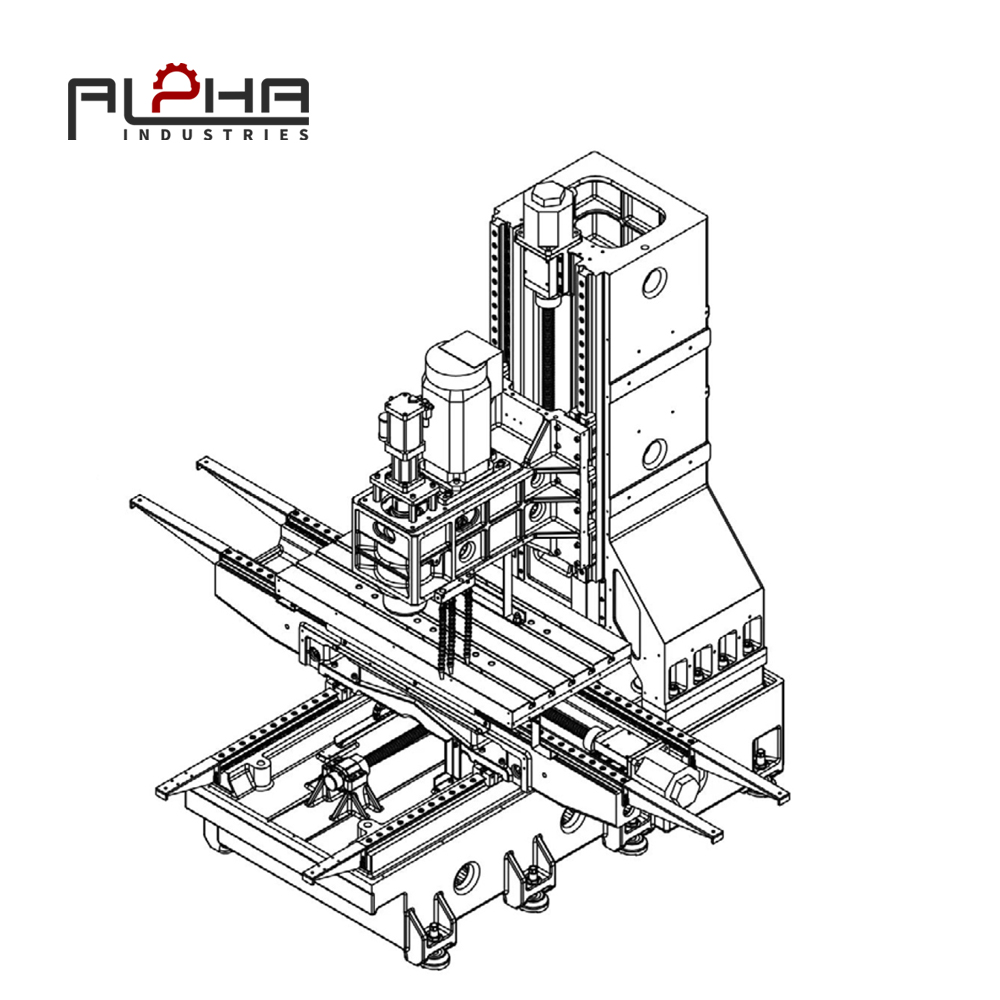

Rigid Structural Design

VMC's T-type column base and Crossing beds reduce vibration and keep the axis aligned, even during heavy-duty cutting.

High-speed, high-precision spindle

equipped with directly drive the spindle to 15,000 rpm, the system minimizes jumping and supports aluminum and titanium processing.

Intelligent control system

Use Siemens or FANUC control units to allow advanced feedforward control of 3D geometry, pre-processed processing and dynamic turns.

Applications in aviation component manufacturing

Alpha VMC support:

-

Engine housing

-

Wing ribs and frames

-

Aviation-grade fixture

-

Driver mechanism and bracket

Machining process optimization

Using cam integrated tool path simulation, manufacturers can predict matter behavior, optimize cutter angles and reduce tool wear - essential in aerospace grade alloys.

FAQ:

What makes VMC suitable for aerospace component manufacturing?

Aviation processing requires ultra-fine tolerances and consistent accuracy. VMCs with high RPM spindles, rigid casting and dynamic path control (such as those of Alpha) ensure tight tolerance to critical flight components is completed.

How does thermal compensation improve the accuracy of VMC?

Thermal compensation will expand the heat of the computer during long operation. Alpha VMC uses thermal sensors and compensation algorithms to adjust real-time positioning to ensure dimensional stability.

Can Alpha's VMC handle titanium and inconel materials?

Yes, the rigid base in the Alpha VMC, a powerful spindle motor and an effective coolant system enable them to easily cut difficult-to-mechanical aerospace alloys such as titanium and inconel.

How does Alpha VMC ensure the repeatability of parts across batches?

Using linear encoders and precision ground ball screws and using closed-loop feedback, Alpha VMCS is crucial for mass production in aerospace.