Introduction to Deburring Techniques

Deburring is a crucial step in manufacturing processes that significantly impacts the quality and functionality of finished products. Whether you’re dealing with wood, metal, plastics, or composites, the deburring process helps remove unwanted burrs and sharp edges formed during production. These imperfections can lead to operational inefficiencies, safety hazards, and diminished product aesthetics. Among the many deburring solutions available, using specialized deburring tools and machines like Alpha Industries' SGP1300 ensures a precise and efficient finish, giving businesses a competitive edge in quality.

Understanding Deburring Methods and Applications

There are various deburring methods, both manual and automated, designed to cater to different material types and project scales. Traditional techniques involve hand tools, files, and abrasive brushes to eliminate burrs. While effective for low-volume tasks, manual deburring can be labor-intensive and less consistent. For high-volume production, deburring machines provide a seamless and efficient alternative.

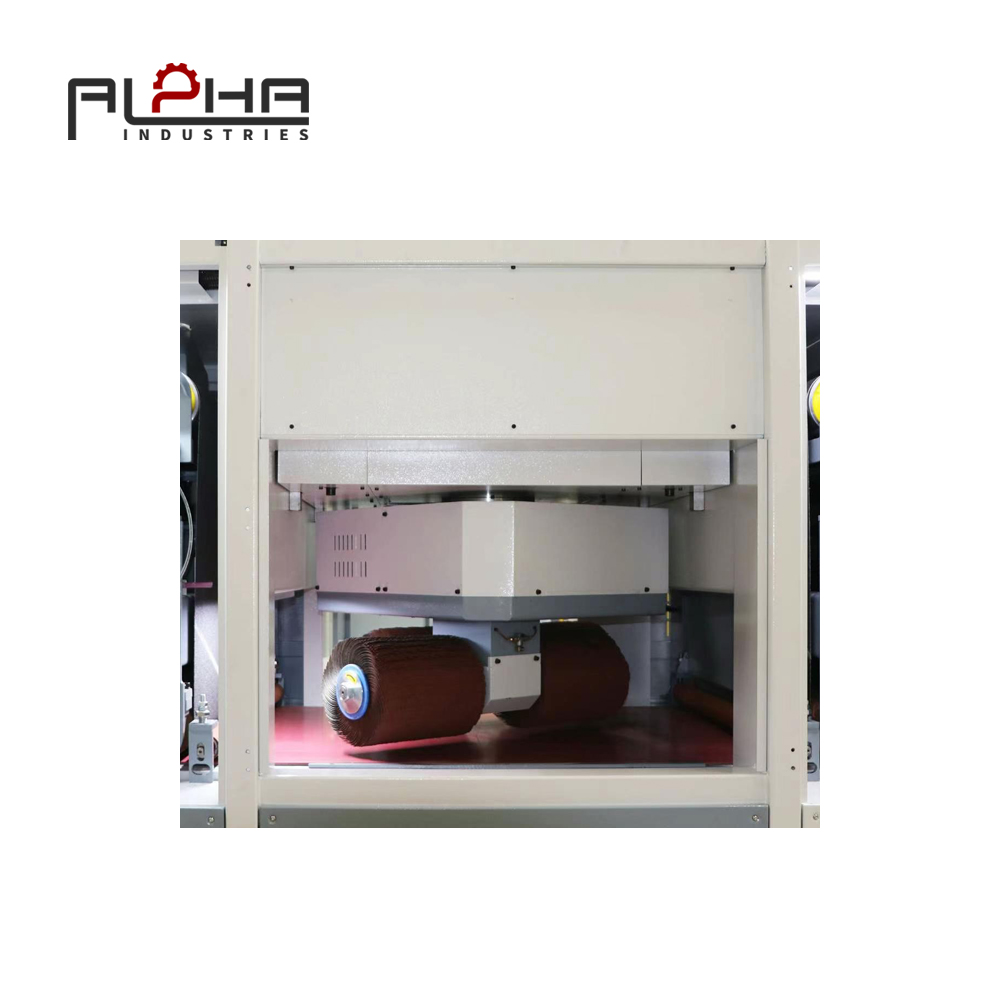

Automated deburring, such as that achieved with the SGP1300 from Nanjing Alpha CNC Co., Ltd, combines high performance with precision. It is suitable for tasks like sanding, grinding, and polishing, ensuring that surfaces are not only burr-free but also refined to the required finish. The machine’s versatility allows it to handle a range of applications, from smoothening furniture surfaces to enhancing the sheen on industrial metal panels. With adjustable settings, the SGP1300 delivers impeccable results tailored to specific project needs, making it a preferred choice in deburring solutions.

The SGP1300: Redefining Performance and Versatility

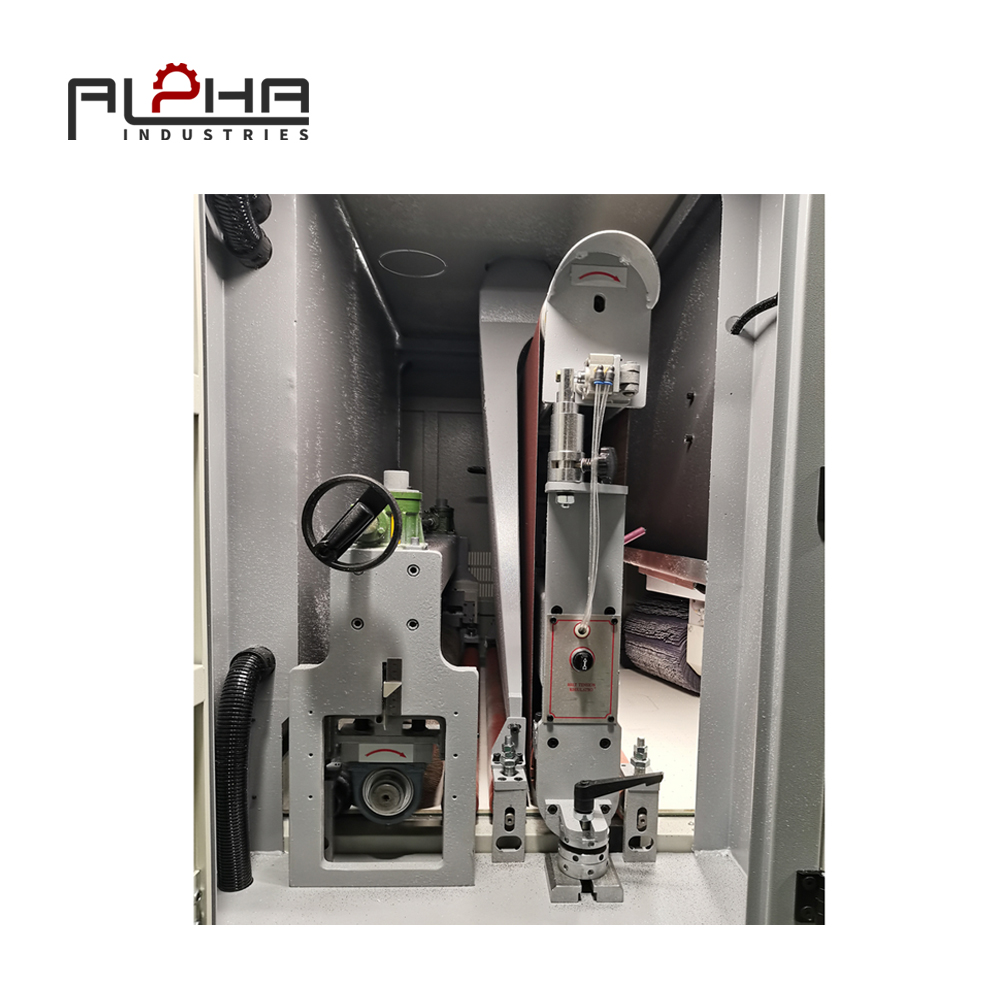

The SGP1300 from Alpha Industries is a cutting-edge deburring machine designed to excel in precision surface preparation. Its industrial-grade motor, sleek design, and user-friendly interface make it a powerful ally in achieving consistent and polished results every time. Compact yet robust, this machine easily integrates into workspaces without compromising functionality.

Key features include:

1. **Industrial Precision**: Perfectly suited for wood, metals, plastics, and composites, ensuring a polished and consistent finish across all materials.

2. **High-Performance Motor**: Powers through demanding tasks, making it a reliable choice for professional applications.

3. **Safety and Usability**: Emergency stops, protective shields, and an intuitive interface ensure operations are efficient and secure.

These attributes position the SGP1300 as a must-have solution, elevating automated deburring processes for businesses. Plus, its angular, modern aesthetic complements the contemporary look of industrial settings, proving that functionality and design can coexist.

Why Choose Nanjing Alpha CNC?

At Nanjing Alpha CNC Co., Ltd, the focus is not just on selling machinery but on providing comprehensive solutions. With expertise in research and development, the company ensures that products like the SGP1300 meet the highest industry standards. Customers benefit from personalized support, whether acquiring a single machine or setting up complete production lines. Quick responses, safe shipping, and competitive pricing further add to Alpha Industries’ commitment to excellence.

By leveraging cutting-edge technologies, the company bridges the gap between innovation and practical application, enabling businesses to achieve unparalleled productivity and precision. Whether you’re engaged in small-scale handicrafts or managing large-scale industrial operations, the deburring applications enabled by the SGP1300 are bound to elevate your end results.

Conclusion

Deburring is an indispensable part of any manufacturing process, and choosing the right deburring tools or machines can make all the difference. With advancements like the SGP1300 from Alpha Industries, automated deburring has become more efficient, versatile, and user-friendly. Businesses can now ensure flawless finishes while maintaining safety, quality, and productivity.

If you’re searching for deburring solutions that combine innovation, efficiency, and reliability, look no further than Alpha Industries and the SGP1300. Eliminate burrs effortlessly, refine surfaces with precision, and take your manufacturing process to the next level.