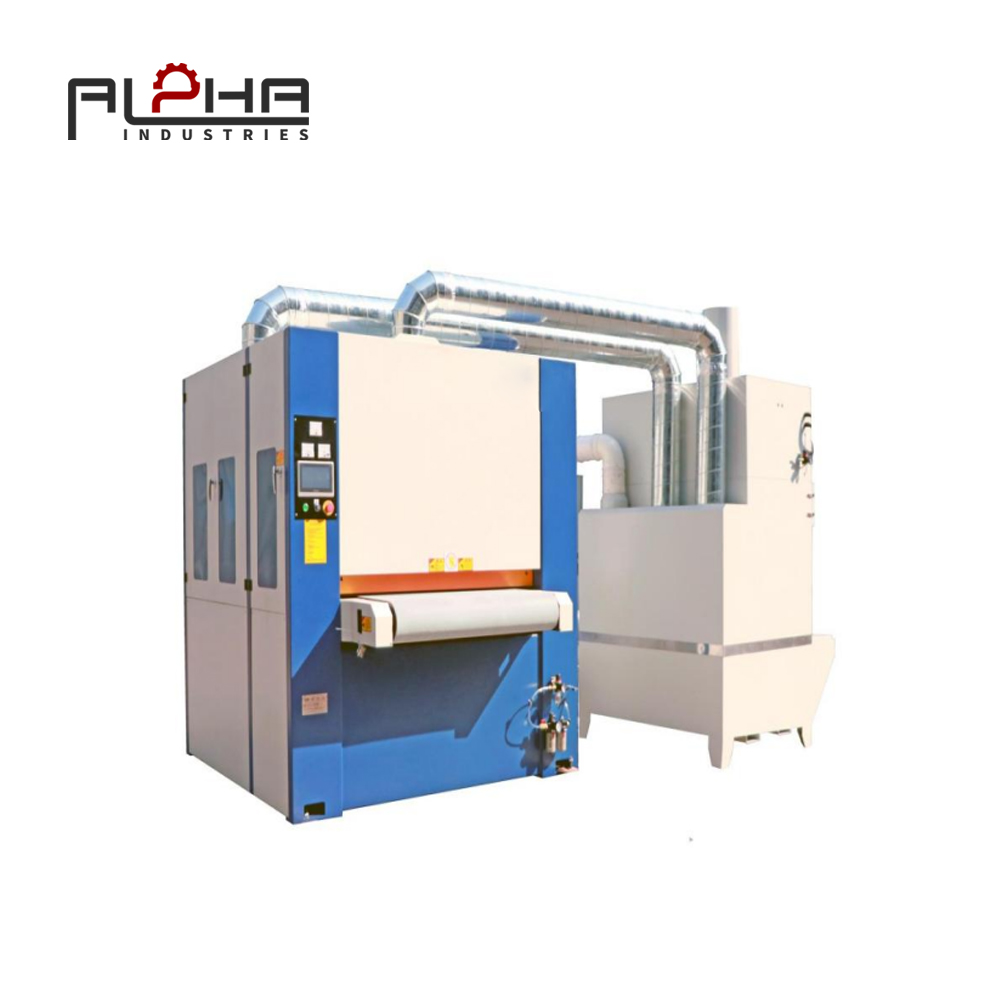

What is a Deburring Machine?

A Deburring Machine is specialized equipment designed to remove burrs, sharp edges, and residual particles generated during metal cutting, punching, laser cutting, or machining processes. Burrs, if not treated, can affect product assembly, coating adhesion, and overall aesthetics.

By using abrasive belts, brushes, or grinding discs, the machine smooths edges, polishes surfaces, and enhances the dimensional accuracy of metal components.

Modern automatic deburring machines are widely applied in sheet metal fabrication, automotive, aerospace, and machinery manufacturing.

Working Principle of Deburring Machine

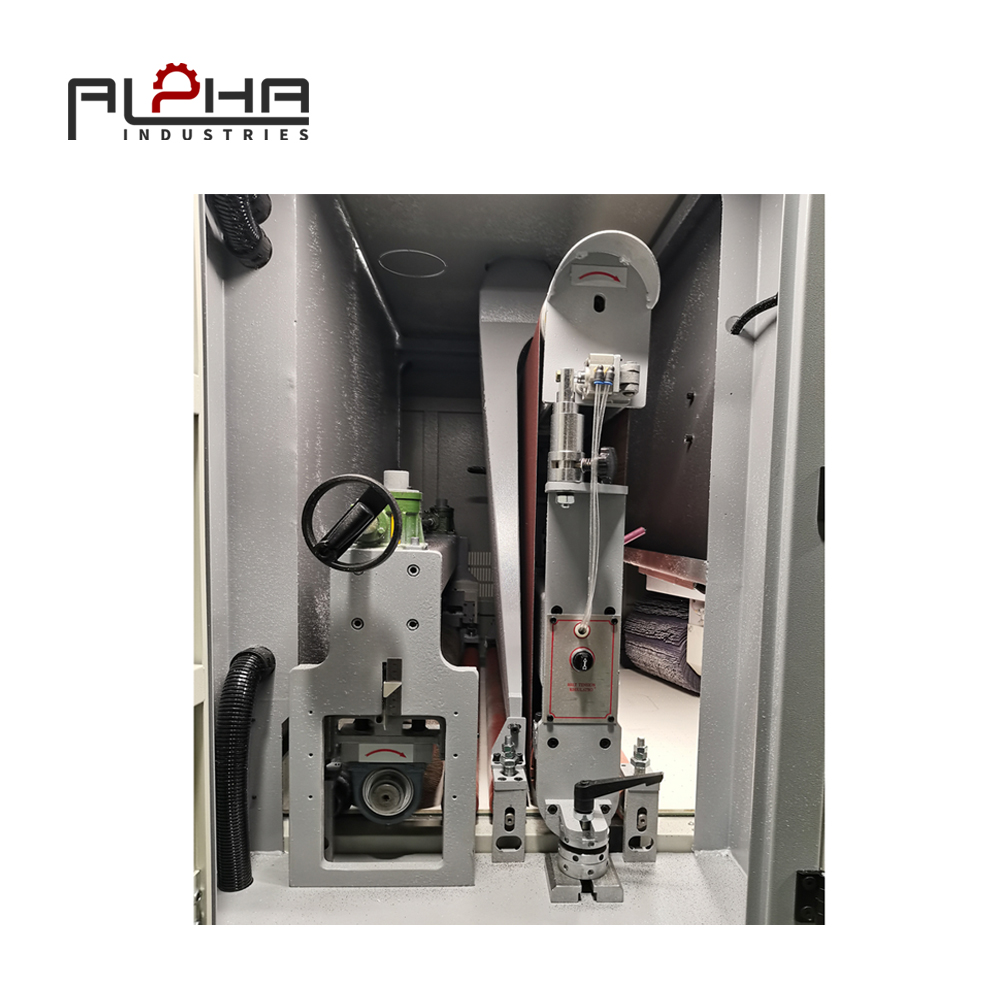

The deburring machine operates through mechanical abrasion using rotating brushes, belts, or discs that contact the workpiece surface.

Depending on the configuration, deburring can handle both single-sided and double-sided processing for metal sheets and parts.

Step-by-Step Process:

-

Feeding – The metal workpiece enters the machine via a conveyor system.

-

Abrasive Processing – Brushes or belts rotate to remove burrs and oxide layers.

-

Edge Rounding – Specialized rotary brushes round sharp corners to prevent injury or coating failure.

-

Dust Extraction – A built-in vacuum system removes metal dust and debris.

-

Discharge – The finished parts exit with a clean, smooth surface ready for painting or assembly.

This process ensures uniform surface quality, enhanced safety, and precise edge control.

Key Features of Deburring Machine

1) Automatic Deburring System

Fully automated feeding, processing, and discharging system for continuous, high-efficiency production.

2) Multi-Station Design

Combines abrasive belts, cross brushes, and oscillating discs to achieve comprehensive surface treatment.

3) Edge Rounding and Oxide Removal

Simultaneous deburring, edge rounding, and oxide removal ensure perfect coating adhesion and corrosion resistance.

4) Adjustable Pressure & Speed

Operators can control the processing force, brush rotation, and feed speed to handle different materials and thicknesses.

5) Dust Collection System

Equipped with an industrial-grade vacuum system to maintain a clean working environment and protect operators’ health.

Advantages of Using a Deburring Machine

-

Enhanced Surface Quality: Smooth, burr-free finish ready for painting or powder coating.

-

Improved Safety: Rounded edges eliminate sharp hazards.

-

Higher Efficiency: Automatic feeding system reduces manual labor and production time.

-

Consistent Results: Uniform finishing across all parts ensures product consistency.

-

Material Versatility: Suitable for stainless steel, aluminum, copper, mild steel, and galvanized sheets.

Technical Specifications (Example Reference)

| Model | Working Width | Material Thickness | Belt Speed | Brush Motor Power | Weight |

|---|---|---|---|---|---|

| DB1000 | 1000 mm | 0.5–80 mm | 2–10 m/min | 3 kW × 2 | 1600 kg |

| DB1300 | 1300 mm | 0.8–100 mm | 3–12 m/min | 4 kW × 2 | 2200 kg |

| DB1600 | 1600 mm | 1–120 mm | 3–15 m/min | 5.5 kW × 2 | 2800 kg |

Applications of Deburring Machine

Deburring machines are essential in:

-

Sheet Metal Fabrication – Removal of burrs after laser or plasma cutting.

-

Automotive Manufacturing – Smoothing parts for engine, body, and chassis components.

-

Aerospace Industry – Precision finishing of aircraft parts to meet strict tolerance standards.

-

Machinery Production – Surface finishing of gears, plates, and housings.

-

Electrical & Electronic Equipment – Ensuring safe, burr-free enclosures and panels.

Maintenance and Operation Tips

-

Regularly inspect brushes and belts for wear and replace when necessary.

-

Keep the dust collection filters clean for efficient suction.

-

Calibrate brush height and pressure before each production batch.

-

Lubricate moving parts periodically to extend machine life.

-

Follow the safety manual and check emergency stop functions regularly.

Why Choose a Deburring Machine from Alpha

At Alpha, we specialize in designing high-performance deburring and edge rounding systems for industrial sheet metal processing.

Our machines are built for precision, durability, and operator safety, featuring:

-

Modular design for different production needs

-

Intelligent control system with variable speed adjustment

-

Anti-vibration steel structure for long-term stability

-

CE and ISO-certified safety and quality compliance

We provide customized solutions for laser-cut, punched, or machined parts to ensure smooth edges, excellent coating performance, and superior finish quality.

FAQ About Deburring Machine

Q1: What is deburring and why is it important?

Deburring removes sharp edges and burrs from metal parts, improving safety, assembly fit, and product appearance.

Q2: What materials can be processed by a deburring machine?

It can process stainless steel, aluminum, mild steel, copper, and galvanized sheets.

Q3: What types of deburring machines exist?

Common types include belt-type, brush-type, vibratory, and wet deburring machines, each suitable for different finishing requirements.

Q4: How to choose the right deburring machine?

Consider the material type, part size, burr severity, and required surface finish when selecting a model.

Q5: Can a deburring machine also polish surfaces?

Yes, many models integrate surface finishing and polishing functions for a complete one-step process.

Call to Action

Looking for a professional Deburring Machine manufacturer?

Contact Alpha today to get your customized edge finishing solution and quotation.