Deburring Process Optimization – The Key to Perfect Metal Finishing

In modern manufacturing, machining processes such as cutting, drilling, milling, and punching are essential to shape metal components. However, almost every machining operation produces an unavoidable by-product: burrs.

These small unwanted edges or fragments may appear insignificant, but they can seriously affect product quality, assembly performance, and even user safety. That is why deburring has become one of the most important finishing processes in metalworking.

At Alpha, we focus on providing professional deburring solutions to help manufacturers achieve cleaner, safer, and more precise products.

What Is Deburring and Why Is It Necessary?

Deburring is the process of removing sharp edges, rough projections, or small material residues left on a workpiece after machining.

Burrs commonly appear after operations such as:

-

Laser cutting

-

Punching

-

Milling

-

Drilling

-

Sawing

-

Grinding

If burrs are not properly removed, they can lead to multiple problems:

-

Difficulty in assembly

-

Poor surface coating adhesion

-

Risk of injury to operators

-

Reduced product performance

-

Dimensional inaccuracy

-

Premature wear of moving parts

Therefore, deburring is not an optional step — it is a critical stage of quality control.

The Hidden Cost of Ignoring Deburring

Many factories underestimate the importance of deburring, focusing only on primary machining speed. However, neglecting burr removal can cause significant hidden costs:

-

Higher rejection rates

-

Additional manual rework

-

Delays in production

-

Customer complaints

-

Damage to brand reputation

A professional and stable deburring process ensures that parts move smoothly to the next production stage without unnecessary interruptions.

Main Deburring Methods in Industrial Production

There is no single universal deburring method. The correct solution depends on material, part geometry, and production volume.

(1) Manual Deburring

Using files, scrapers, or abrasive tools.

-

Low cost

-

Flexible

-

Suitable for small batches

-

Inconsistent quality

(2) Mechanical Deburring

Using specialized deburring machines.

-

High efficiency

-

Stable results

-

Ideal for mass production

(3) Abrasive Belt or Brush Deburring

Widely used for sheet metal parts.

-

Uniform surface finish

-

Suitable for flat components

(4) Vibratory Deburring

For small parts in bulk.

-

Good for complex shapes

-

Automated processing

(5) Thermal and Chemical Deburring

Used in high-end precision industries.

-

Removes internal burrs

-

Higher cost

Among these methods, mechanical deburring machines provide the best balance of efficiency, consistency, and cost — which is the core focus of Alpha.

Why Automated Deburring Machines Are Essential

As labor costs rise and quality requirements become stricter, manual deburring is no longer sufficient for modern factories.

Automated deburring machines offer clear advantages:

-

Consistent edge quality

-

Higher production speed

-

Lower labor dependency

-

Repeatable processing results

-

Improved workplace safety

For manufacturers aiming to upgrade production lines, investing in professional deburring equipment is a key step toward intelligent manufacturing.

Key Factors in Choosing the Right Deburring Machine

Selecting the correct deburring system is critical for long-term success.

Important considerations include:

-

Material type (steel, aluminum, stainless steel)

-

Part thickness

-

Burr size

-

Surface finish requirement

-

Production volume

-

Integration with existing workflow

Alpha provides customized consultation to help customers choose the most suitable deburring solution.

How Deburring Improves Product Quality

Proper deburring directly enhances multiple aspects of a product:

-

Smoother edges for safer handling

-

Better coating and painting adhesion

-

Improved dimensional accuracy

-

Longer service life of components

-

Higher overall product value

In industries such as automotive, aerospace, and electronics, high-quality deburring is essential to meet strict standards.

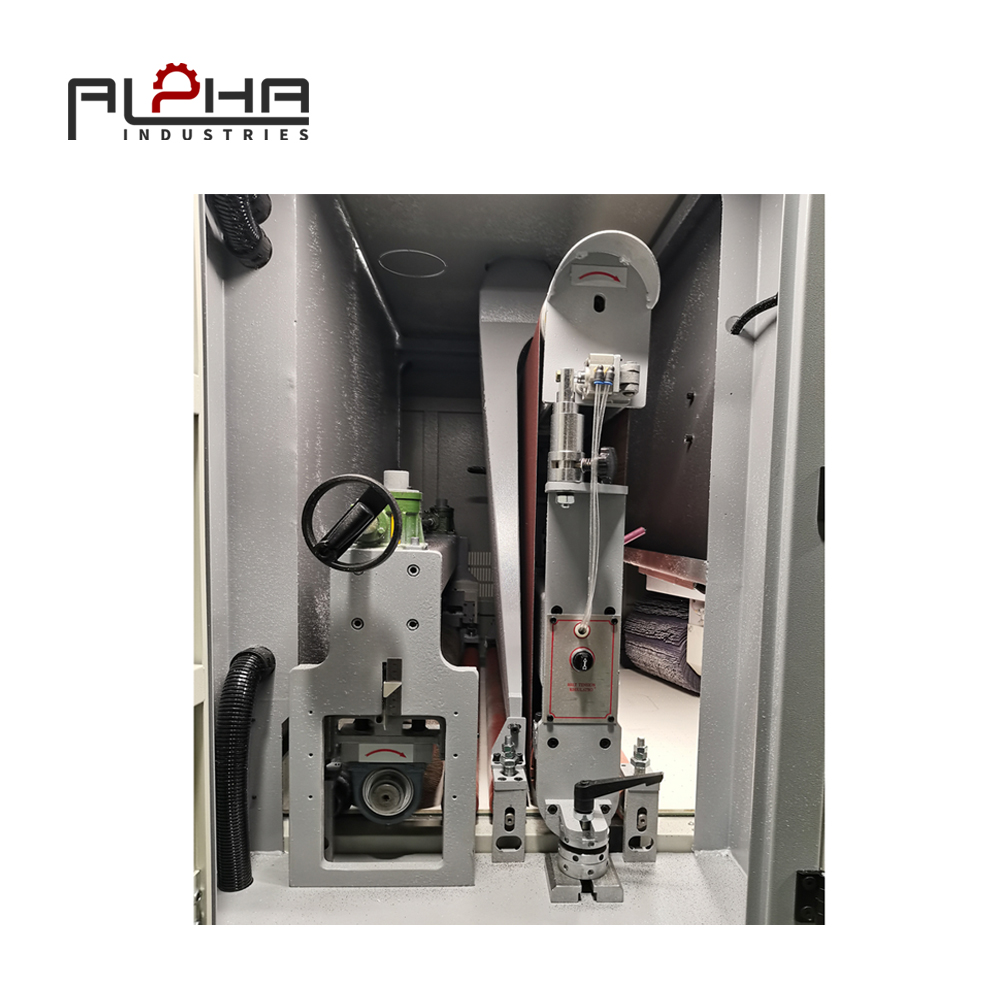

Alpha Deburring Solutions – Built for Industrial Efficiency

Alpha designs and manufactures professional deburring machines for various industrial applications.

Our equipment features:

-

High-precision abrasive systems

-

Adjustable processing parameters

-

Durable industrial structure

-

Easy maintenance

-

Stable and repeatable performance

-

Suitable for different materials and part sizes

With Alpha deburring machines, customers can achieve:

-

Faster throughput

-

Lower rejection rates

-

Better surface quality

-

Reduced manual labor

Deburring in Different Industries

Deburring plays a crucial role in many fields:

-

Sheet metal fabrication

-

Automotive components

-

Aerospace parts

-

Medical devices

-

Electronic enclosures

-

Precision machinery

Each industry has unique requirements, and Alpha offers tailored solutions to meet them.

Future Trends in Deburring Technology

With the development of smart manufacturing, deburring is also evolving toward:

-

Fully automated production lines

-

Robotic deburring systems

-

Intelligent parameter control

-

Higher precision finishing

Alpha continues to innovate to keep customers competitive in a rapidly changing market.

Frequently Asked Questions

Q1: What is deburring?

Deburring is the process of removing burrs and sharp edges left on parts after machining operations.

Q2: Why is deburring important?

It improves safety, product quality, assembly performance, and surface finish.

Q3: Can burrs affect product performance?

Yes. Burrs can cause poor fitting, coating failure, and even mechanical malfunction.

Q4: What is the most efficient deburring method?

For mass production, automated mechanical deburring machines are the most efficient and stable solution.

Q5: How do I choose the right deburring machine?

Selection depends on material, burr size, part shape, and production volume. Alpha can provide professional guidance.

Conclusion

In modern manufacturing, deburring is no longer just a finishing step — it is a critical quality process.

Without effective burr removal, even perfectly machined parts cannot meet real-world application requirements. A professional deburring system ensures:

-

Higher product quality

-

Safer operation

-

Faster production flow

-

Lower overall cost

At Alpha, we are committed to helping global manufacturers optimize their deburring processes with reliable equipment and technical expertise.

If you are looking for a professional partner to upgrade your deburring capability, Alpha is ready to support you.

- Explore our full product range: Alpha Industrial Machinery

-

Need technical support or a quotation? Contact Us