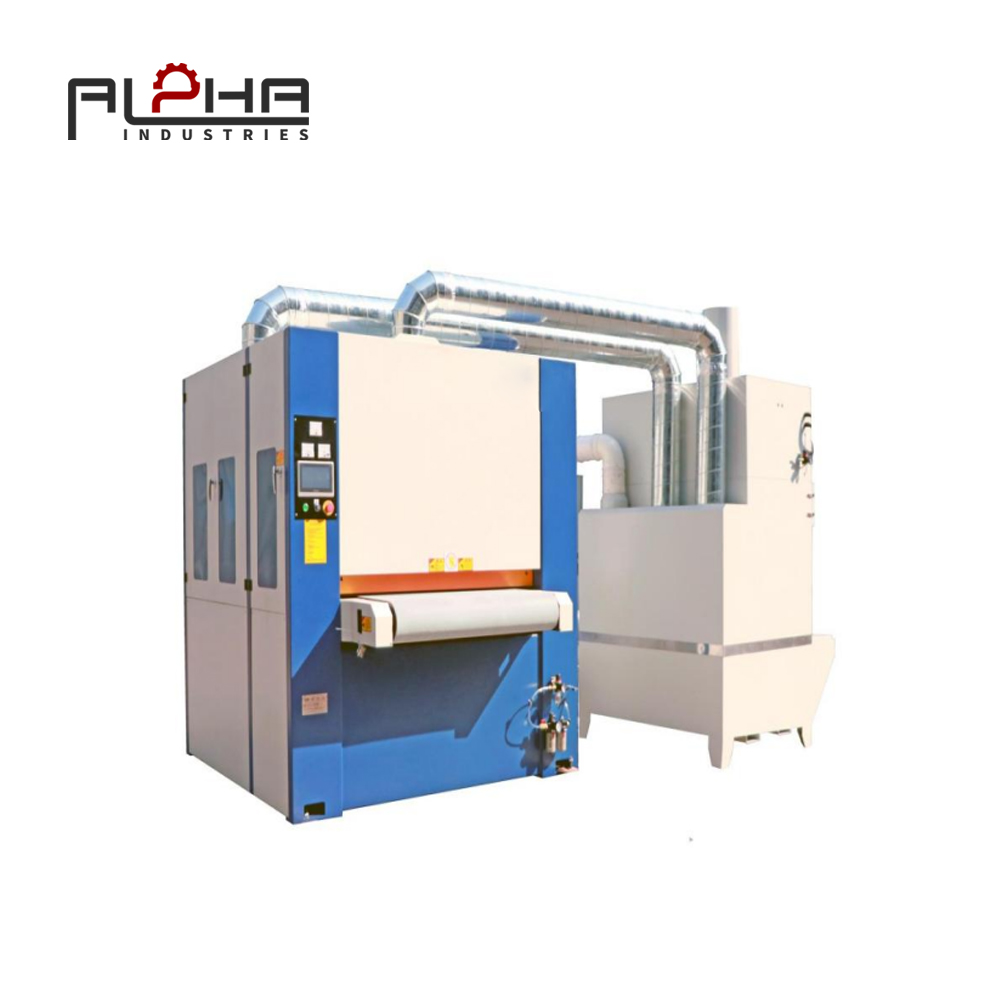

Automated Deburring for Sheet Metal – Efficiency and Quality Optimization

In today’s competitive manufacturing environment, productivity and quality are equally important. Sheet metal processing technologies such as laser cutting, punching, and stamping have become faster and more precise than ever before. However, one problem remains unavoidable after almost every cutting process — burrs.

Burrs may be small, but their impact on final product quality is enormous. That is why deburring has become a critical step in modern metal fabrication lines. Among all deburring approaches, automated deburring for sheet metal has proven to be the most effective and stable solution.

At Alpha, we specialize in developing professional automated deburring machines that help manufacturers achieve higher efficiency, better quality, and lower overall production cost.

The Real Challenge of Burrs in Sheet Metal Production

When sheet metal is processed by laser cutting, punching, or shearing, tiny sharp edges and material residues are inevitably created along the cutting lines. These burrs may seem minor, but they bring many serious problems:

-

Sharp edges that can injure operators

-

Difficulty during part assembly

-

Poor powder coating or painting adhesion

-

Inaccurate part dimensions

-

Unstable product performance

-

Increased rejection rate

For companies focused on high-end manufacturing, leaving burrs on parts is simply unacceptable.

Therefore, a reliable and efficient deburring process is not optional — it is a mandatory quality control step.

Why Manual Deburring Is No Longer Enough

Traditionally, many factories relied on manual deburring using hand tools. While this method works for small batches, it has major disadvantages:

-

Low efficiency

-

Inconsistent results

-

High labor cost

-

Operator fatigue

-

Difficult to control quality

-

Not suitable for large-volume production

As production volumes grow and labor costs rise, manual deburring becomes a bottleneck that limits overall factory performance.

This is exactly why automated deburring technology has become the industry standard.

The Core Advantages of Automated Deburring

Automated deburring machines bring a series of significant improvements to sheet metal processing:

(1) Stable and Consistent Quality

Machines deliver uniform edge finishing regardless of operator skill.

(2) Higher Production Efficiency

Large quantities of parts can be processed continuously in a short time.

(3) Lower Labor Dependency

One operator can manage the entire deburring process.

(4) Safer Working Environment

No direct contact with sharp metal edges.

(5) Better Surface Treatment Results

Ideal preparation for painting, coating, or further finishing.

For modern smart factories, automated deburring is a key step toward digital and intelligent manufacturing.

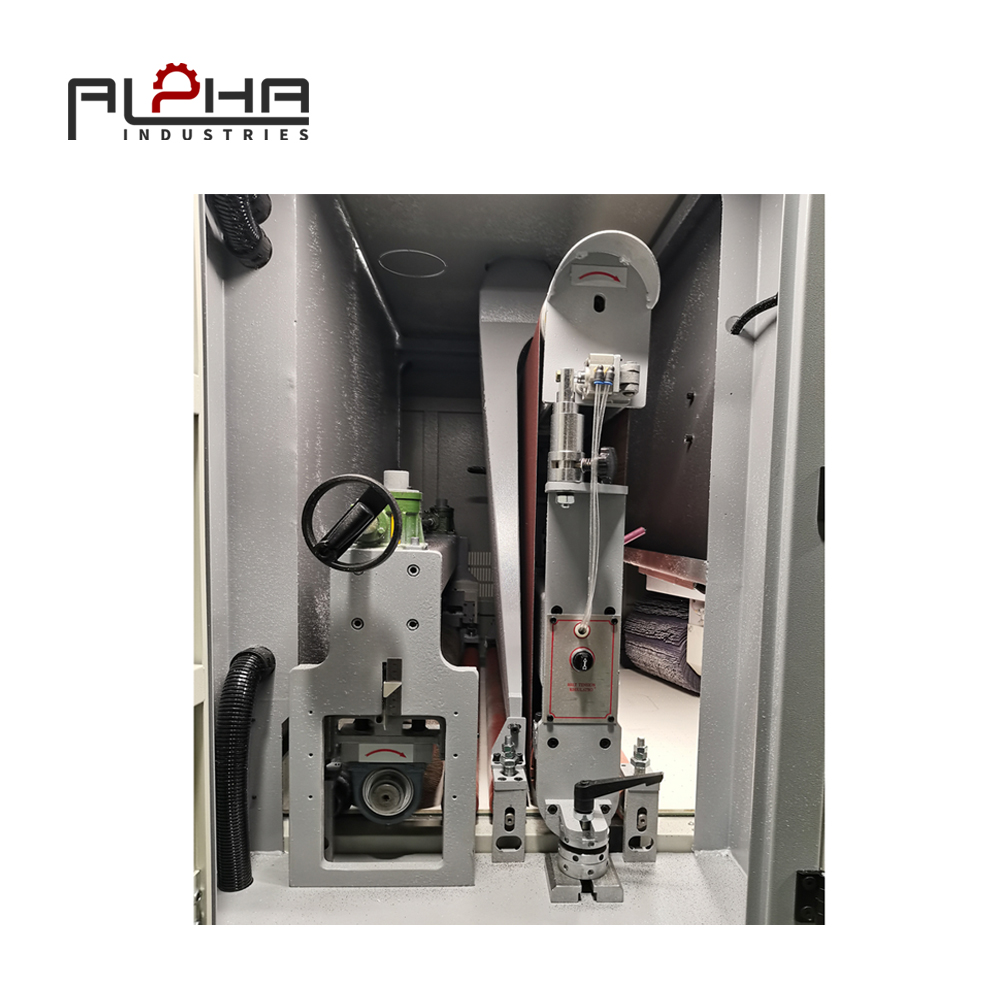

How Automated Deburring Machines Work

A professional sheet metal deburring machine typically includes:

-

Abrasive belts or grinding rollers

-

Rotating brushes

-

Adjustable pressure systems

-

Conveyor feeding mechanisms

-

Dust extraction systems

Parts pass through the machine once or multiple times, and burrs are removed uniformly from all edges and surfaces.

This process ensures:

-

Smooth edges

-

Clean surfaces

-

Controlled material removal

-

Repeatable results

Key Factors in Deburring Process Optimization

To achieve the best deburring effect, several technical factors must be carefully considered:

-

Material type (aluminum, carbon steel, stainless steel)

-

Sheet thickness

-

Burr size and hardness

-

Required surface finish

-

Processing speed

-

Abrasive tool selection

Optimizing these parameters is essential for maximizing efficiency while protecting part accuracy.

Alpha provides professional technical support to help customers fine-tune their deburring process.

Industries That Depend on Automated Deburring

Automated deburring is widely used in:

-

Sheet metal fabrication

-

Electrical enclosures

-

Automotive components

-

Elevator parts

-

Kitchen equipment

-

Construction hardware

-

Precision machinery

Any industry that processes large volumes of metal parts can benefit greatly from automated deburring technology.

How Alpha Helps Customers Improve Deburring Performance

Alpha designs and supplies advanced deburring machines tailored for industrial users.

Our deburring equipment offers:

-

Adjustable processing parameters

-

Strong and durable structure

-

Easy operation

-

Low maintenance cost

-

Excellent processing stability

-

Compatibility with various materials

With Alpha deburring machines, customers can achieve:

-

Higher throughput

-

Better edge quality

-

Reduced rework

-

Improved customer satisfaction

Deburring as a Key Step in Smart Manufacturing

As Industry 4.0 develops, factories are moving toward fully automated production lines. Deburring is becoming an integrated process connected with:

-

Laser cutting machines

-

Robotic handling systems

-

Automatic sorting lines

-

Digital quality control

Alpha continues to innovate to provide intelligent deburring solutions that fit modern smart factories.

Frequently Asked Questions

Q1: What is deburring in sheet metal processing?

Deburring is the process of removing sharp edges and burrs created during cutting, punching, or machining operations.

Q2: Why is automated deburring important?

Automated deburring ensures consistent quality, higher efficiency, lower labor cost, and safer operation.

Q3: Can burrs affect product quality?

Yes. Burrs can cause assembly problems, poor coating adhesion, and even safety risks.

Q4: What is the best method for large-volume deburring?

For mass production, automated mechanical deburring machines are the most efficient and reliable option.

Q5: How do I choose the right deburring machine?

Selection depends on material type, part thickness, burr size, and required surface finish. Alpha provides professional consultation.

Conclusion

In sheet metal manufacturing, cutting and forming are only the beginning. The final quality of a product largely depends on how well burrs are removed.

Automated deburring is the key to:

-

Stable product quality

-

High production efficiency

-

Lower operational cost

-

Safer working conditions

For companies aiming to upgrade their production lines and compete in global markets, investing in professional deburring technology is a smart and necessary decision.

At Alpha, we are dedicated to providing reliable, high-performance deburring machines and complete technical support to help manufacturers achieve perfect metal finishing.

Explore our complete product range: Alpha Industrial Machinery

Need technical support or a quotation? Contact Us