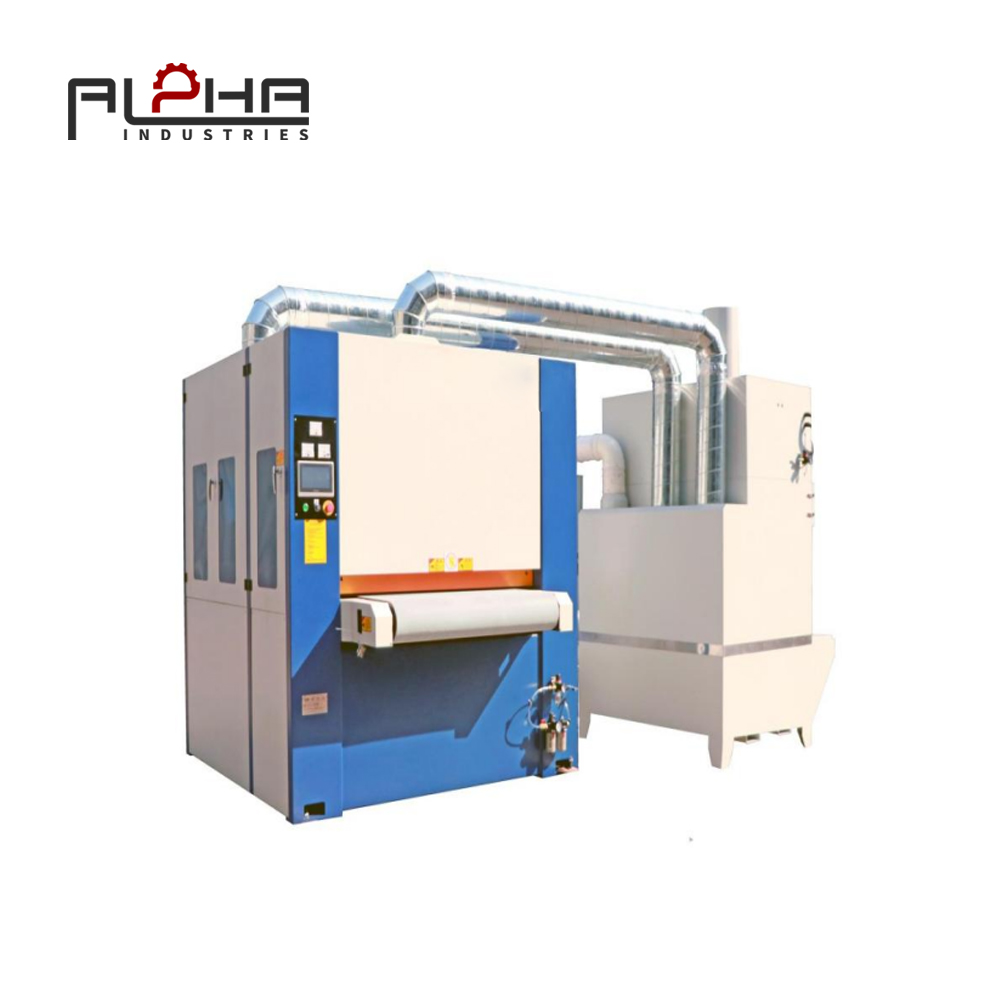

Polishing Machine – The Key to Superior Metal Surface Quality

In modern manufacturing, product quality is no longer judged only by dimensional accuracy or structural strength. Surface appearance and finish quality have become equally important standards. Whether it is stainless steel products, automotive parts, household appliances, or decorative components, the final visual and tactile impression largely depends on one critical process — polishing.

This is where the polishing machine plays a decisive role. A professional polishing system transforms rough machined surfaces into smooth, bright, and aesthetically pleasing finishes. For manufacturers aiming to produce high-end products, polishing machines are no longer optional equipment, but essential production tools.

At Alpha, we specialize in providing advanced polishing machine solutions that help global customers achieve higher quality standards and greater production efficiency.

What Is a Polishing Machine?

A polishing machine is an industrial device designed to improve the surface finish of metal parts through mechanical friction and abrasive action. By using polishing wheels, belts, or compounds, the machine gradually removes micro-level surface imperfections and creates a smooth, uniform surface.

Typical materials processed by polishing machines include:

-

Stainless steel

-

Aluminum

-

Brass

-

Copper

-

Carbon steel

-

Various alloys

Polishing machines are widely used to achieve different levels of surface finish, ranging from basic smoothing to high-gloss mirror effects.

Why Polishing Is Crucial in Metal Manufacturing

Many manufacturers focus heavily on machining accuracy but overlook surface treatment. However, poor surface quality can cause several problems:

-

Unattractive product appearance

-

Poor resistance to corrosion

-

Weak coating adhesion

-

Difficult cleaning and maintenance

-

Reduced market value

A high-quality polishing process directly improves:

-

Product aesthetics

-

Functional performance

-

Durability

-

Customer satisfaction

Therefore, polishing is a vital step in transforming semi-finished parts into premium products.

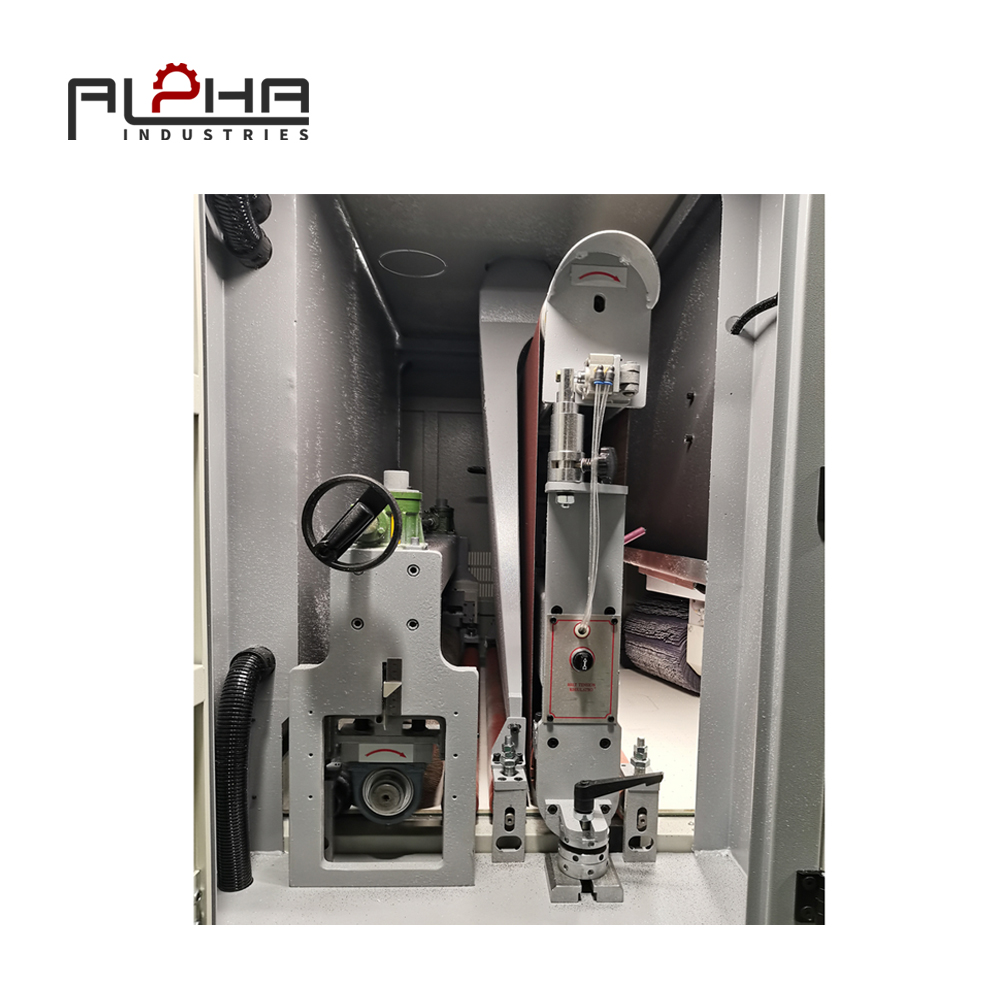

How Industrial Polishing Machines Work

The working principle of a polishing machine is based on controlled friction between the workpiece and abrasive tools.

Main components usually include:

-

Polishing wheels or belts

-

High-speed drive motor

-

Pressure control system

-

Workpiece holding fixture

-

Speed adjustment mechanism

-

Dust collection system

By adjusting rotation speed, pressure, and abrasive type, operators can achieve different surface effects such as:

-

Satin finish

-

Brushed finish

-

Matte surface

-

Mirror polish

This flexibility makes polishing machines suitable for a wide range of industrial applications.

Key Advantages of Using a Professional Polishing Machine

Compared with manual polishing, industrial polishing machines provide clear benefits:

(1) Consistent Surface Quality

Machines deliver uniform results independent of operator skill.

(2) Higher Efficiency

Large volumes of parts can be polished in a short time.

(3) Lower Labor Cost

Automation significantly reduces manual workload.

(4) Repeatable Results

Processing parameters can be precisely controlled.

(5) Safer Working Environment

Less direct human contact with abrasive materials.

For companies targeting stable and large-scale production, polishing machines are indispensable.

Types of Polishing Machines

Different products require different polishing solutions. Common types include:

-

Flat surface polishing machines

-

Tube and pipe polishing machines

-

Automatic rotary polishing machines

-

Robotic polishing systems

-

Vibratory polishing equipment

-

Mirror polishing machines

Choosing the right type depends on:

-

Workpiece shape

-

Material

-

Required finish

-

Production volume

Alpha provides a full range of polishing machines to meet diverse industrial needs.

Industries That Rely on Polishing Machines

Polishing technology is essential in many sectors:

-

Kitchen equipment manufacturing

-

Automotive parts

-

Medical instruments

-

Architectural decoration

-

Furniture hardware

-

Electronics housings

-

Aerospace components

In these industries, surface quality is often as important as functional performance.

Manual Polishing vs. Machine Polishing

| Factor | Manual Polishing | Machine Polishing |

|---|---|---|

| Efficiency | Low | High |

| Consistency | Unstable | Excellent |

| Labor cost | High | Low |

| Surface quality | Operator-dependent | Uniform |

| Production capacity | Limited | Large-scale |

This comparison clearly shows why more and more factories are switching to automated polishing machines.

How Alpha Polishing Machines Improve Your Production

Alpha designs polishing machines specifically for industrial applications with strict quality requirements.

Our technical strengths include:

-

Robust and durable structure

-

Precise speed control

-

Adjustable pressure system

-

Easy operation interface

-

Low maintenance design

-

Stable long-term performance

With Alpha polishing machines, customers can achieve:

-

Higher productivity

-

Better surface consistency

-

Reduced rejection rate

-

Lower overall production cost

Choosing the Right Polishing Machine

Selecting the correct machine requires professional evaluation:

-

Material type

-

Part geometry

-

Surface roughness requirement

-

Desired gloss level

-

Production quantity

Alpha offers expert consultation to help customers choose the most suitable polishing solution.

Future Development of Polishing Technology

With the progress of smart manufacturing, polishing machines are developing toward:

-

Full automation

-

Robotic integration

-

Intelligent parameter control

-

Higher precision

-

Environmentally friendly designs

Alpha continuously invests in innovation to keep our customers at the forefront of industrial technology.

Frequently Asked Questions

Q1: What is a polishing machine used for?

A polishing machine is used to smooth, refine, and brighten metal surfaces to improve appearance and performance.

Q2: What materials can be polished?

Most metals such as stainless steel, aluminum, brass, and copper can be effectively polished.

Q3: What is the difference between grinding and polishing?

Grinding removes larger material amounts, while polishing focuses on fine surface finishing and gloss improvement.

Q4: Is machine polishing better than manual polishing?

Yes. Machine polishing provides higher efficiency, better consistency, and lower cost.

Q5: How to choose the right polishing machine?

Selection depends on part shape, material, required finish, and production volume. Alpha can help you make the right choice.

Conclusion

In modern metal manufacturing, surface quality has become a key factor that determines product competitiveness. The polishing machine is the core equipment that turns ordinary metal parts into high-value finished products.

Through professional polishing technology, manufacturers can achieve:

-

Smooth and attractive surfaces

-

Improved corrosion resistance

-

Higher added value

-

Better brand image

-

More satisfied customers

For companies seeking to upgrade product quality and production efficiency, investing in a high-performance polishing machine is a smart and strategic decision.

At Alpha, we are committed to providing reliable, efficient, and advanced polishing machine solutions for customers worldwide.

Explore More Solutions

Learn more about our industrial machinery:

👉 Alpha Industrial Machinery