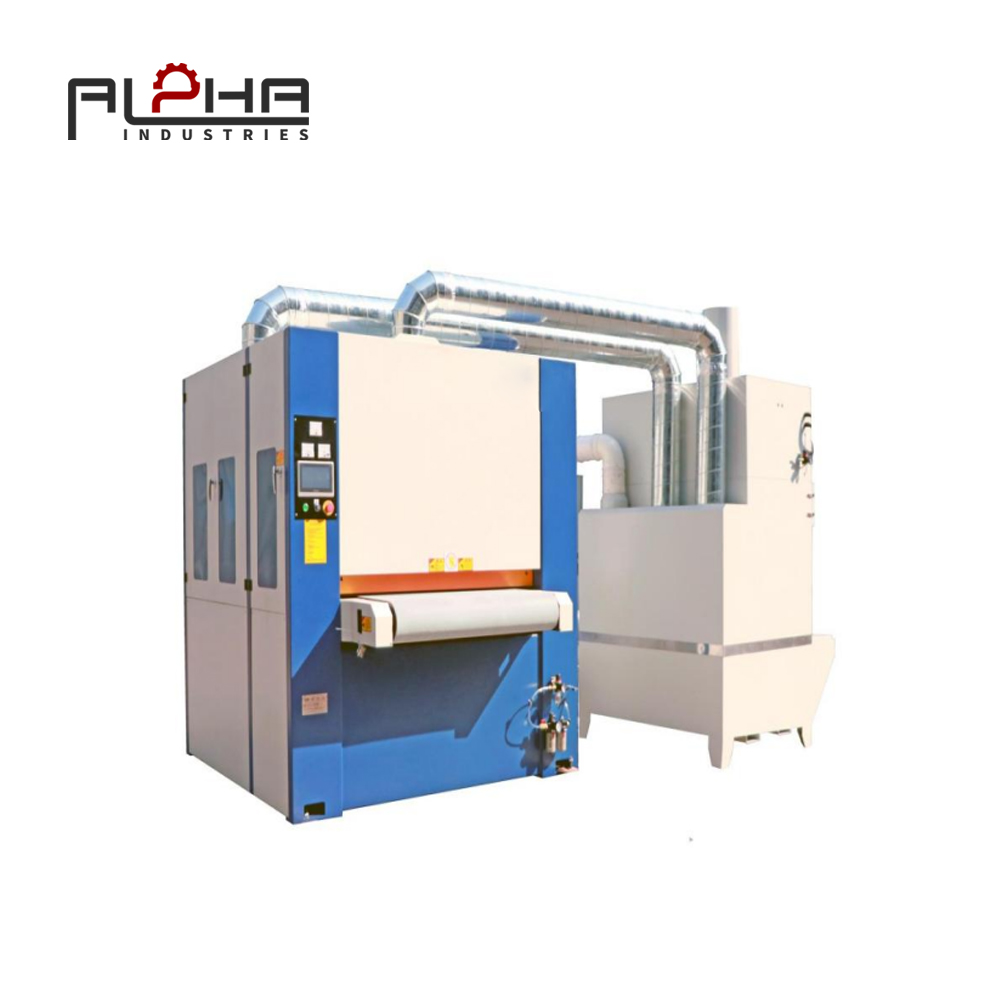

ALPHA Deburring Machines are engineered for high-precision edge finishing of metal components. They remove burrs, sharp edges, and rough surfaces created during machining, punching, or cutting processes.

Our machines are ideal for industries including automotive, aerospace, electronics, and general metal fabrication, ensuring smooth, safe, and high-quality finished products. Explore the ALPHA Deburring Machine product range for models suitable for different materials and production volumes.

Key Features of ALPHA Deburring Machines

-

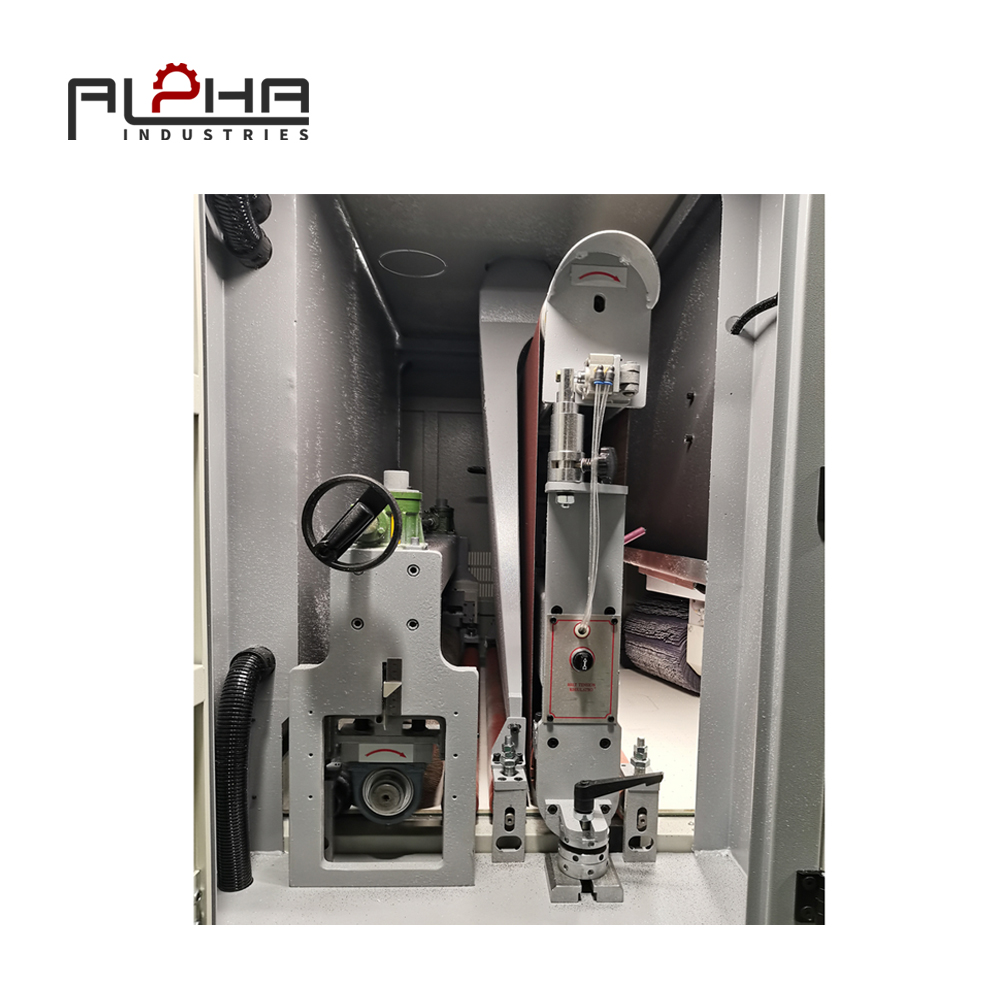

High Precision Burr Removal: Advanced abrasive and brushing systems provide consistent edge finishing.

-

Versatile Operation: Suitable for stainless steel, aluminum, copper, and other metals.

-

Adjustable Speed and Pressure: Optimize deburring for different material thicknesses and surface finishes.

-

Compact and Durable Design: Heavy-duty construction ensures long service life and minimal maintenance.

-

Safety and User-Friendly Controls: Emergency stops and intuitive panels improve operator safety and efficiency.

Learn more about our models on the ALPHA product page.

Applications of ALPHA Deburring Machines

Deburring machines are essential for:

-

Automotive parts finishing (gears, brackets, and housings)

-

Aerospace component edge smoothing

-

Electronic metal component finishing

-

Sheet metal parts and fabricated components

Explore detailed applications in our Deburring Machine applications article.

Common Problems with Deburring Machines and Solutions

Even high-quality machines like ALPHA Deburring Machines may encounter operational challenges. Understanding these helps maintain performance and reduce downtime.

1. Incomplete Burr Removal

Cause: Incorrect speed or abrasive settings.

Solution:

-

Adjust speed and pressure based on material type.

-

Replace worn brushes or abrasive belts.

2. Surface Damage

Cause: Excessive pressure or improper abrasive selection.

Solution:

-

Reduce pressure and choose the correct abrasive type.

-

Test on sample parts before full production runs.

3. Machine Overheating

Cause: Continuous operation or insufficient lubrication.

Solution:

-

Allow cooling intervals during long cycles.

-

Lubricate moving parts regularly.

4. Excessive Vibration or Noise

Cause: Loose components or unbalanced abrasive wheels.

Solution:

-

Tighten bolts and check fixture alignment.

-

Balance abrasive wheels and brushes periodically.

Maintenance Tips for ALPHA Deburring Machines

-

Regularly inspect and replace worn brushes, belts, and abrasive tools.

-

Keep the machine clean and free from metal dust and debris.

-

Lubricate moving components according to the maintenance schedule.

-

Ensure operators follow recommended deburring procedures for different materials.

Contact our support team for maintenance assistance via ALPHA contact page.

Advantages of Choosing ALPHA Deburring Machines

-

High-precision and consistent edge finishing

-

Versatile for different metals and part sizes

-

Durable, low-maintenance construction

-

User-friendly and safe for operators

Explore the full range of ALPHA Deburring Machines to find the best solution for your metal finishing needs.

Get Your ALPHA Deburring Machine Product Brochure

For complete specifications, model options, and technical details, download the ALPHA Deburring Machine brochure here.