Lathe machine is the cornerstone of the manufacturing industry and the foundation for creating cylindrical parts with excellent accuracy. Its evolution is crucial in advancing modern production, thus enabling the creation of essential components in every sector from automobiles to aerospace. The process of precise machining depends largely on the function of the lathe, which makes choosing the right equipment a key decision for any workshop or production facility. Choosing machines that combine powerful structures with complex controls is key to achieving efficiency and top-level results.

Unlock the anatomy of a high-performance lathe

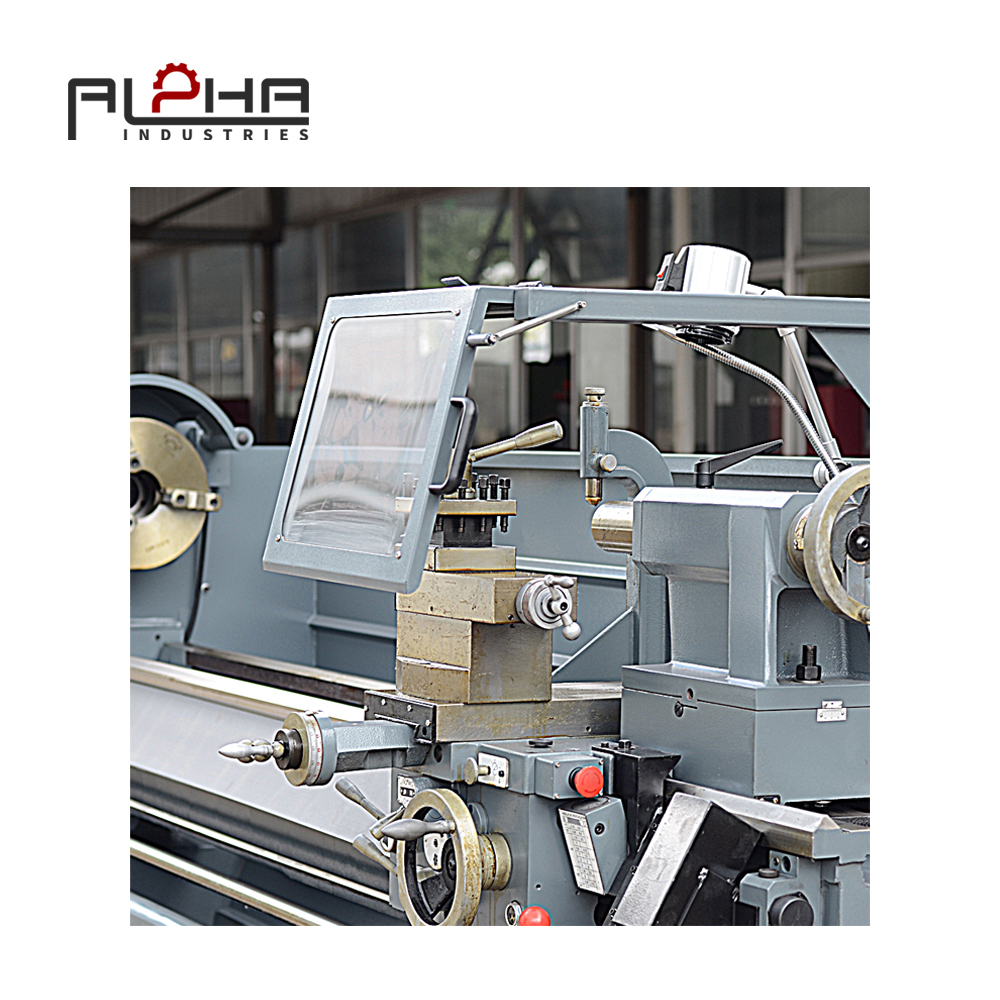

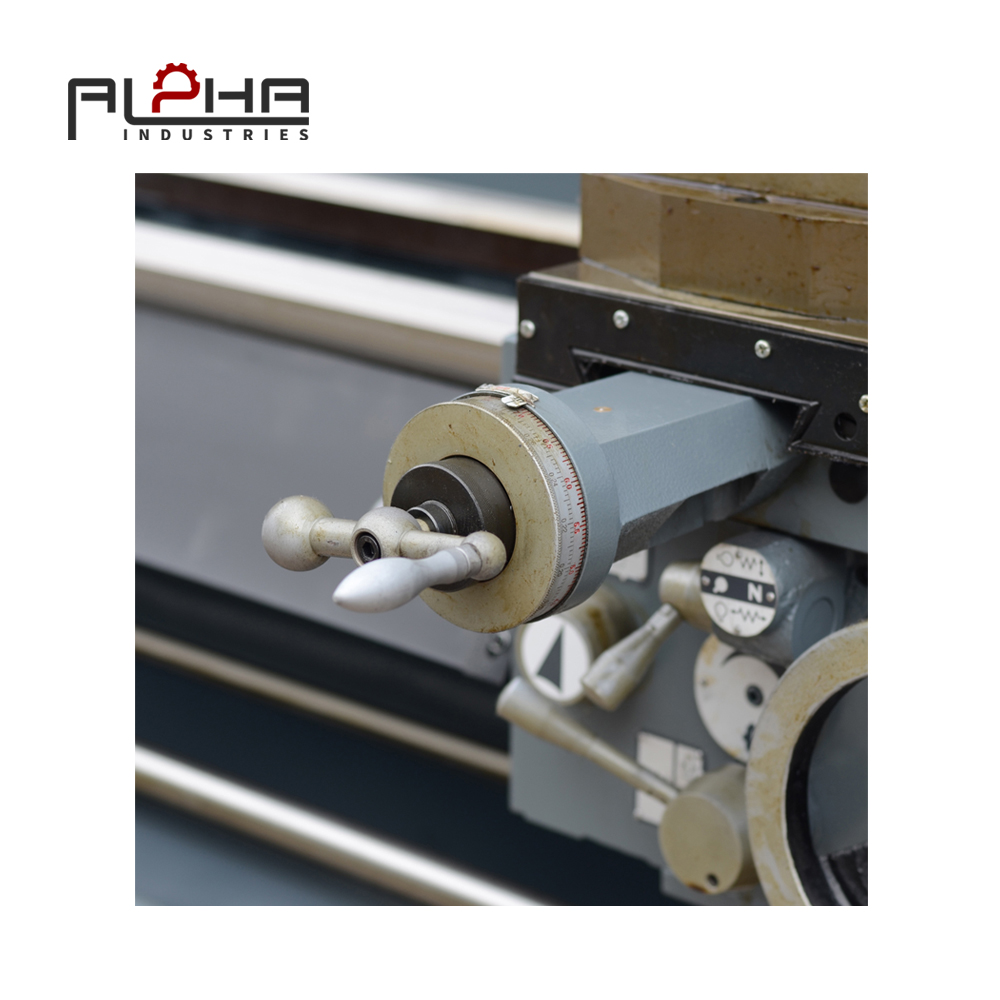

Advanced lathes are defined by the quality of their components and engineering. Premium lathe parts must be built from durable materials, from bedside tables and tails to carriages and beds to withstand the rigor of a demanding work environment. This powerful build prevents wear and corrosion, ensuring longevity and stable performance. Controls including handwheels and levers should allow for micron adjustments, which is crucial for complex tasks. Versatility is another crucial aspect, modern machines offer a range of spindle speeds and feed speeds. This adaptability allows operators to perform different functions using a variety of lathe tools, such as rotation, facing, drilling and thread cutting with the highest accuracy.

Master modern lathe operation

Effective lathe operation is a skill that combines technical knowledge with hands-on expertise. Although traditional manual lathes require important operator skills, the emergence of CNC lathes has revolutionized the industry. Following programming instructions, Computer Numerical Control (CNC) automatically performs the process to perform unparalleled repetition and accuracy. However, today’s best machines often bridge the gap, combining intuitive, user-friendly designs that make complex lathe operation easier for new mechanics while still providing advanced features required by experienced professionals. This focus on ergonomic design and streamlined control maximizes operator efficiency and reduces fatigue, resulting in increased productivity and better finished products.

Find the right partner: The importance of expert lathe suppliers

With a lot of options available, choosing from a large number of lathe suppliers can be a daunting task. The ideal partner is more than just the seller. They are solutions providers dedicated to helping your business succeed. Companies like Nanjing Alpha CNC Co., Ltd provide a reflection of this approach by providing customers with everything from choosing a computer to designing the entire production line. Reputable lathe suppliers have invested heavily in R&D to ensure their products are world-class design and manufactured. They provide comprehensive support, quickly resolve inquiries and ensure that goods are both safe and cost-effective. Working with expert suppliers ensures that you will not only receive high-quality lathe machines, but also seamlessly integrate them into your workflow for the guidance you need to get the best results.

Conclusion: Improve manufacturing capabilities

In short, investing in high-quality lathe machines is a direct investment in your company's future manufacturing. Whether you choose a manual model for custom projects or a complex CNC lathe for mass production, the right equipment is crucial to achieving the highest standards for precise machining. By carefully considering the components, operating functions and the credibility of the lathe supplier of your machine, you can gain strong assets for your business. Working with knowledgeable and supportive providers like Alpha ensures that you not only get world-class machines, but also work together, and work to enhance your operational excellence.