High-quality lathe machine is the cornerstone of modern manufacturing, and it is an essential tool for metals, wood and other materials with excellent accuracy. For businesses in the automotive to aerospace industry, the ability to perform precise processing distinguishes excellent products from great products. The choice of machines, their components and their functions directly affects efficiency, quality and overall operational success. As technology advances, understanding what is looking for in lathes becomes increasingly important to maintain a competitive advantage.

The basis of quality: robust structure and durable parts

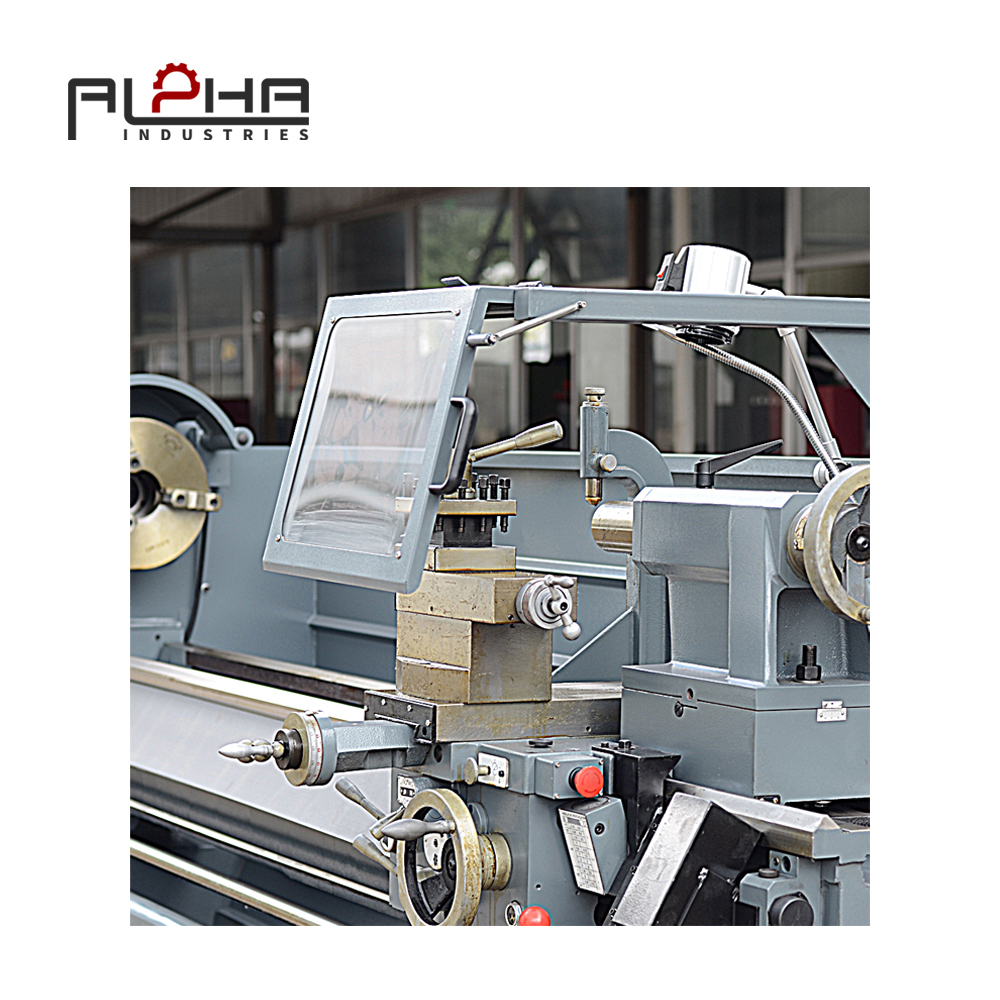

Realizing true precise machining starts with the basic design and construction of the machine. The lathe must be built on a stable and stable frame to minimize vibration and ensure stable performance, even under heavy workloads. The quality of individual lathe parts from the tool transport to the handwheel and spindle is crucial. At Nanjing Alpha CNC Co., Ltd, we understand excellence is the details. Our machines, such as the CR6266CX2300, have components carefully crafted from advanced materials such as premium steel and brass. This commitment to high-quality structure ensures longevity and unwavering accuracy, allowing operators to produce perfect components every time.

User-centered design simplifies operations

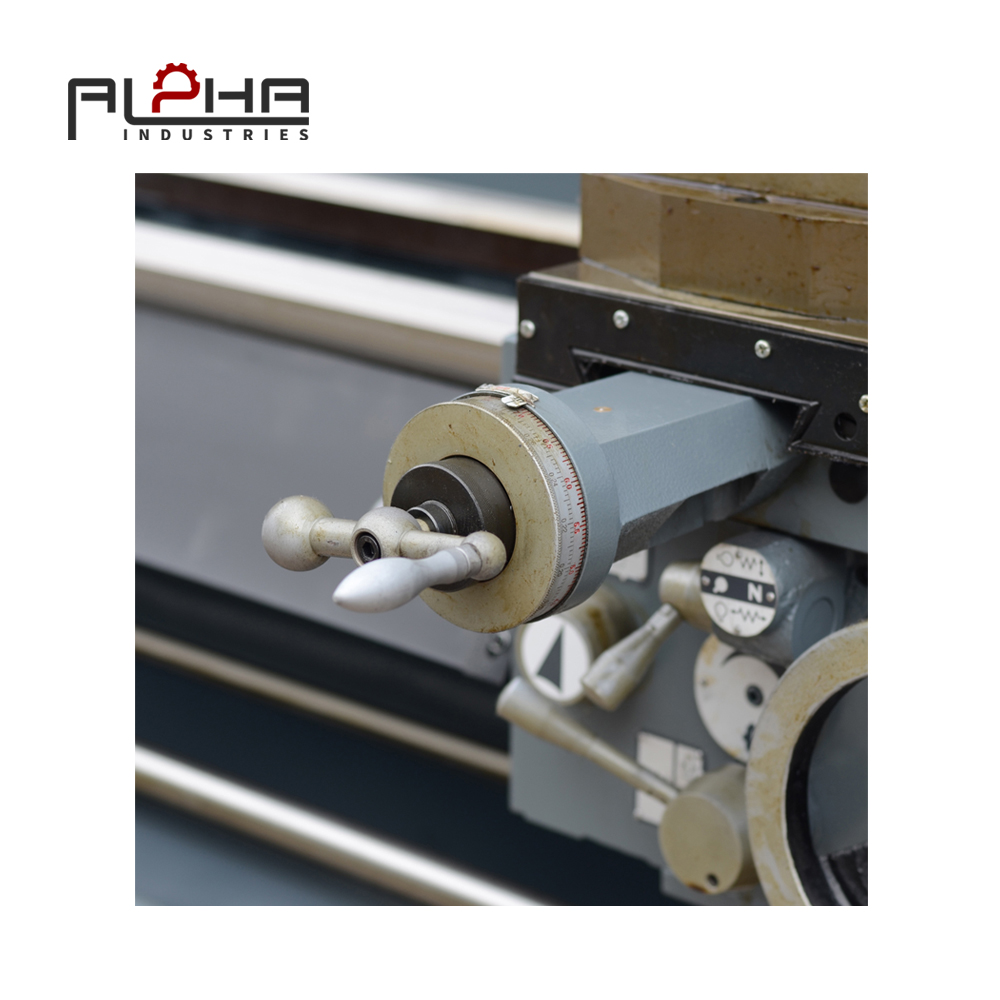

Effective lathe operation depends not only on the original power. It requires an intuitive and ergonomic design that supports the operator. Modern lathes are designed for user convenience, with logical placement levers, clear dials and smooth operating controls. For example, the touch of a well-designed handwheel allows for tiny, easy adjustments, while clearly marked instrumentation and directional controls simplify complex tasks. Whether it is a processing manual or a CNC lathe, the user-friendly interface lowers the learning curve, minimizes errors and increases productivity. This focus on human elements ensures that machines are not only tools, but real partners in production, capable of handling a variety of materials and workpieces without seam transitions.

Versatility and power in modern machining

Today’s manufacturing needs versatility, and top lathes must be able to adapt to a variety of tasks. The effectiveness of a lathe also depends on the lathe tool it can support and the complexity of the operations it can perform. Our CR6266CX2300 model exemplifies this principle. They are carefully designed to handle a wide range of materials and applications, from making small and complex parts to managing large-scale manufacturing. Features like precise nozzles and multi-function carriages allow workshops to expand their capabilities and carry out more challenging projects. This adaptability combines powerful performance to make our machines fundamental assets for any facility designed to promote productivity and unparalleled results.

Find more than just machines: Choose a reliable lathe supplier

Obtaining advanced machinery is a significant investment to choose a lathe supplier as important as the machine itself. A great supplier not only needs to sell equipment, but also can do more. They provide comprehensive solutions. At Nanjing Alpha CNC Co., Ltd, we are proud to be a solution provider. Our professional R&D team ensures world-class design, while our dedicated customer service team provides timely expert support. We provide customers with safe and cost-effective transportation from choosing a machine to designing a complete production line. Working with knowledgeable and supported suppliers guarantees that you not only receive an excellent lathe machine, but also gain a valuable ally dedicated to helping your business grow and improve its manufacturing standards.