In the world of manufacturing and metal manufacturing, the final finish of a component is as crucial as its initial design. The key step in this finishing phase is the process of removing small, unwanted raised edges or ridges on the metal parts after processing operations such as cutting, drilling or stamping. These burrs can affect the function, safety and aesthetic quality of the parts. Therefore, adopting an effective industrial basis process is not optional. This is a basic requirement for producing high-quality, reliable and safe products.

The Challenge of Traditional Burr

For decades, manufacturers have relied on manual methods and basic burr tools to smooth the metal edges. This approach, while working to some extent, is full of challenges. Manual basis is incredibly labor-intensive, time-consuming, and can lead to inconsistencies between parts. The quality of the finish is often dependent on the skill and expertise of the individual operator, which leads to high potential for human error. Additionally, this manual labor increases operating costs and can expose workers to repeated strain injury and safety risks due to handling sharp metal components. Traditional Deburring tools are often not suitable for complex geometry, nor are they suitable for the high tolerance needed in modern industries such as aerospace, automotive and electronics.

Transition to automatic glitch solutions

To overcome the limitations of manual processes, the industry has turned to more complex glitch solutions. The emergence of automatic burrs has completely changed how manufacturers approach part finishes. By leveraging advanced machinery, companies can achieve unparalleled consistency, speed and accuracy, with manual methods simply not matching. Automated systems reduce labor costs, increase throughput and greatly improve worker safety through direct contact with parts during the burr process. Investing in high-quality burr machines is no longer a luxury, but a strategic necessity for any business looking to maintain a competitive advantage and provide flawless products.

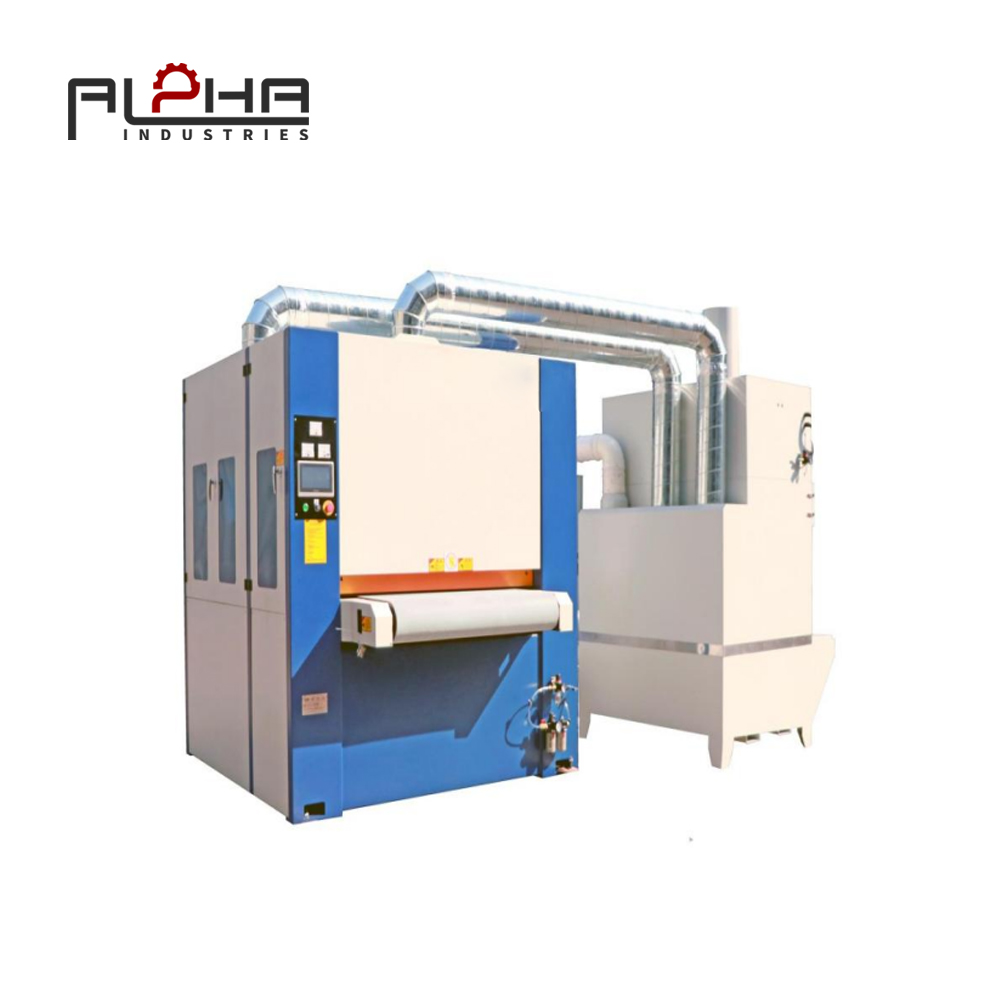

Meet Alpha Grinding System: The Ultimate Grease Machine

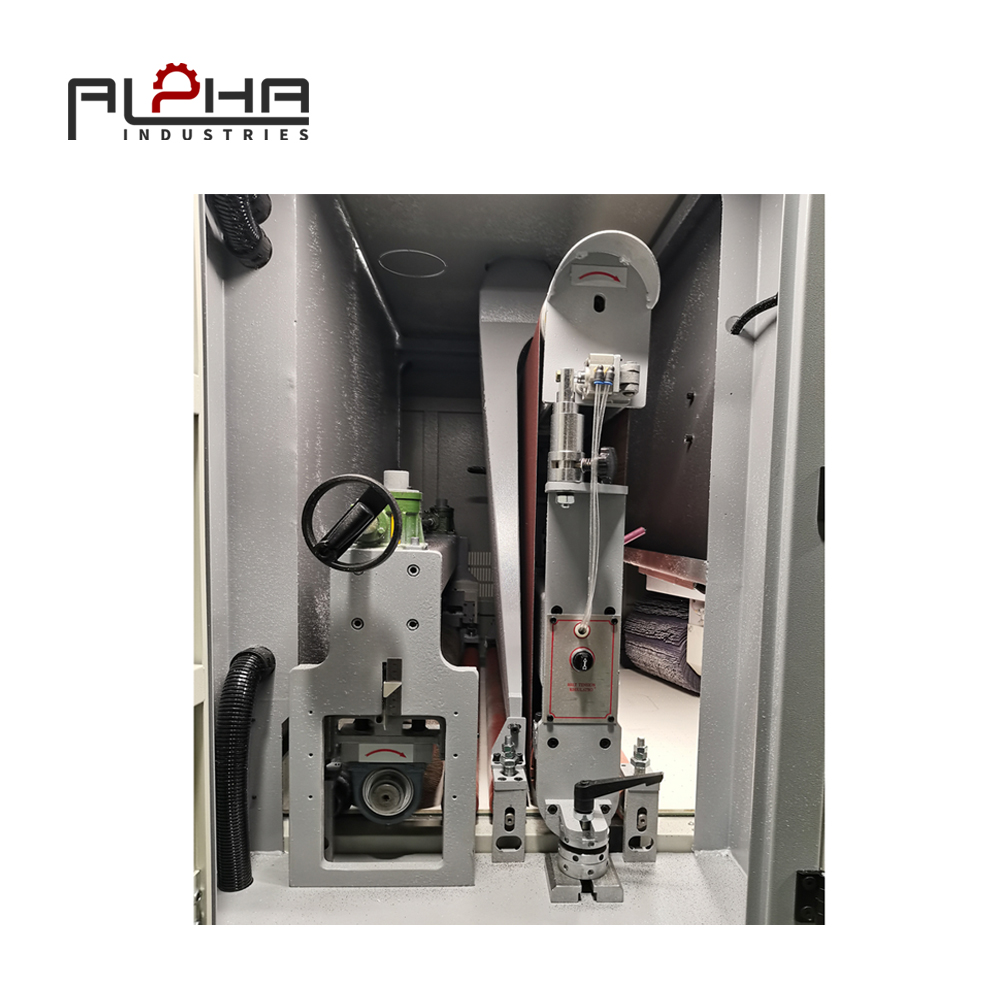

The forefront of this technological development is the Alpha Sanding System, a cutting-edge machine designed to provide perfect finishes. It's not just a sander. This is a comprehensive solution specially designed for precise burrs and finishing. The machine features a user-friendly control panel with analog meter and modern touch screen interface, giving the operator complete control of the process for precise specifications. Its wide, adjustable table can accommodate a wide variety of materials and part sizes, making it versatile for any workshops for efficient and high-quality metal burrs.

Designed for performance and clean workspaces

The reason for setting up the Alpha grinding system is its thoughtful engineering and robust structure. Built in durable metal shells, this Deburring Machine is designed to perform long-term in demanding industrial environments. A key feature is its professionally integrated dust extraction system. This powerful system captures air particles at the source, ensuring a clean, safe workspace that protects operator health and reduces machine maintenance. The commitment to performance and safety makes it an ideal platform for meticulously accurate basis without compromise. The combination of powerful motors, stable working surfaces and effective dust management ensures perfect results for each component.

您的合作伙伴以完成毛刺解决方案

At Nanjing Alpha CNC Co., Ltd, we learn that achieving excellence in manufacturing requires not only machinery. It requires partnerships. We are proud to be a solution provider, helping our customers from one machine to a complete production line. Our professional R&D team ensures that our equipment represents world-class design and capabilities. When you invest in an Alpha system, you are not just buying a machine. You are getting a partner dedicated to a comprehensive glitch solution tailored to your unique needs. We are committed to helping you improve your business with advanced technology and reliable support.